|

|

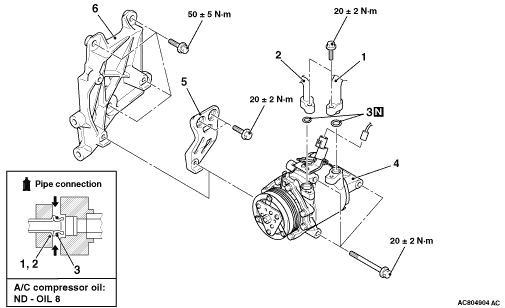

Plug the removed nipple of the pipe, hose and expansion valve to prevent the entry of

dust and dirt.

|

|

|

Be careful not to spill the A/C compressor oil and remove the A/C compressor.

|

|

|

When installing the new A/C compressor, install the A/C compressor after

adjusting the oil volume as follows.

|

|

|

1.Measure the oil of A/C compressor removed.(X mL )

|

|

|

2.Drain the oil (Y mL) given by the following expression from a new A/C compressor,

and then install the A/C compressor.

130 mL - X mL = Y mL

| note |

- 130 mL shows the oil volume contained in the new A/C compressor.

- Y mL shows the oil volume stored in the refrigerant line, condenser, and cooling

unit, etc.

|

|

.)

.) <134>, GROUP

11C, On-Vehicle Service, Drive Belt Tension Check And Adjustment

<134>, GROUP

11C, On-Vehicle Service, Drive Belt Tension Check And Adjustment  <135> or

GROUP 11E, On-Vehicle Service, Drive Belt Tension Check And Adjustment

<135> or

GROUP 11E, On-Vehicle Service, Drive Belt Tension Check And Adjustment  <4G1>.)

<4G1>.)