|

|

Q.

Which turn-signal lamp fails to illuminate correctly?

|

|

|

Front turn-signal lamp : Go to Step 2. : Go to Step 2.

|

|

|

|

|

|

Side turn-signal lamp : Go to Step 9. : Go to Step 9.

|

|

|

|

|

|

Rear turn-signal lamp : Go to Step 16. : Go to Step 16.

|

|

|

|

|

|

All lamps on the right side do not illuminate. : Go to Step 23. : Go to Step 23.

|

|

|

|

|

|

All lamps on the left side do not illuminate. : Go to Step 24. : Go to Step 24.

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 3. Go to Step 3.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

|

Check the bulb(s) of the defective lamp.

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the bulb(s) of the defective lamp. Go to Step 25. Replace the bulb(s) of the defective lamp. Go to Step 25.

|

|

|

|

|

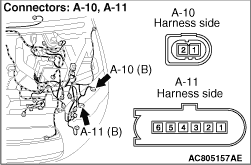

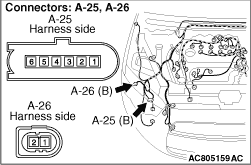

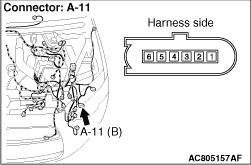

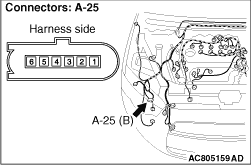

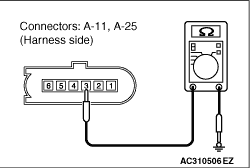

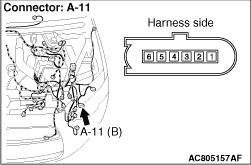

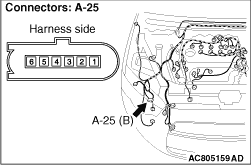

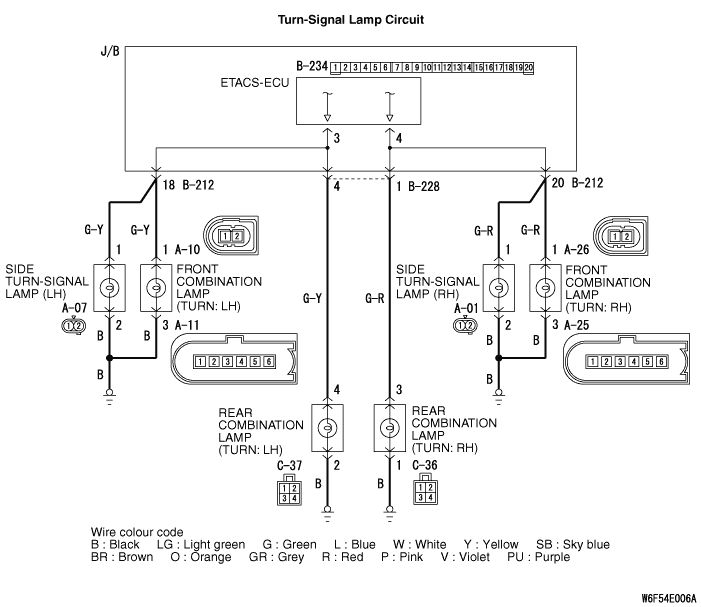

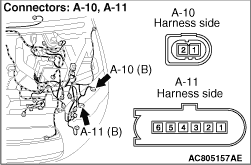

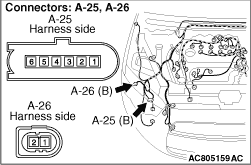

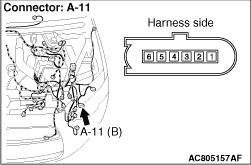

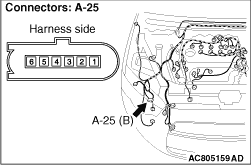

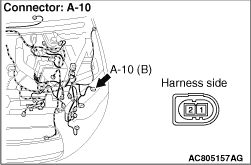

(1)Disconnect the connector, and measure at the wiring harness side.

|

|

(2)Resistance measurement between the defective lamp connector terminal and body earth.

- Resistance between A-11 front combination lamp (turn: LH) connector terminal

No.3 and body earth

- Resistance between A-25 front combination lamp (turn: RH) connector terminal No.3

and body earth

OK: Continuity exists (2 Ω or less)

Q.

Is the check result normal?

Go to Step 6. Go to Step 6.

Go to Step 5. Go to Step 5.

|

|

- Check the earth wires for open circuit.

Q.

Is the check result normal?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25. ). Go to Step 25.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

Q.

Is the check result normal?

Go to Step 7. Go to Step 7.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

| note |

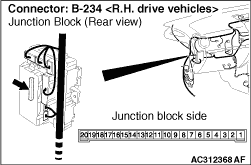

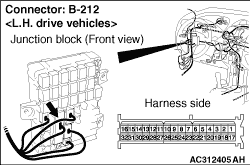

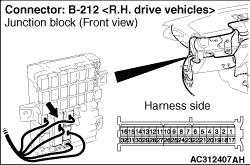

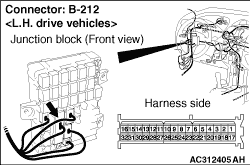

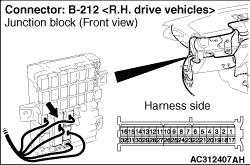

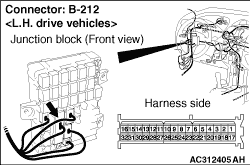

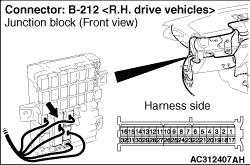

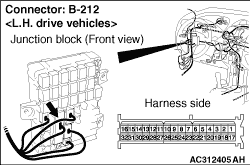

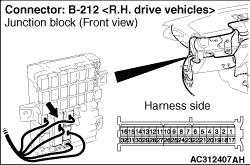

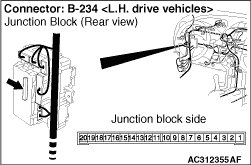

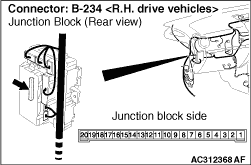

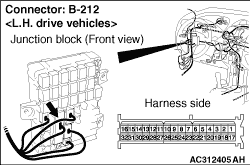

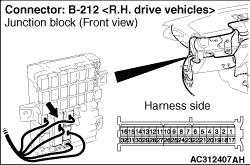

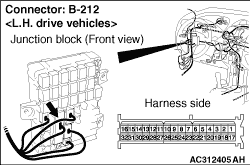

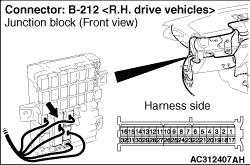

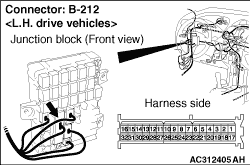

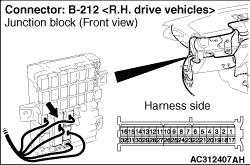

Prior to the wiring harness inspection, check junction block connector B-212, and repair

if necessary.

|

- Check the output lines for open circuit.

Q.

Is the check result normal?

Go to Step 8. Go to Step 8.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

|

Check that the front turn-signal lamps illuminate normally.

|

|

|

Q.

Is the check result normal?

|

|

|

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25. ). Go to Step 25.

|

|

|

|

|

|

Replace the front combination lamp. Go to Step 25. Replace the front combination lamp. Go to Step 25.

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 10. Go to Step 10.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

|

Check the bulb(s) of the defective lamp.

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the bulb(s) of the defective lamp. Go to Step 25. Replace the bulb(s) of the defective lamp. Go to Step 25.

|

|

|

|

|

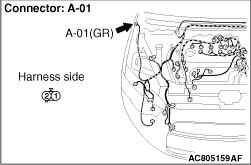

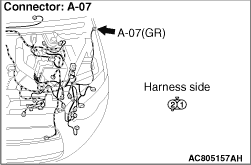

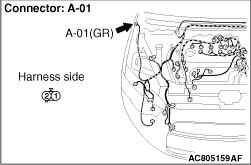

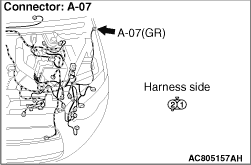

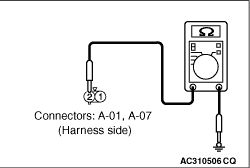

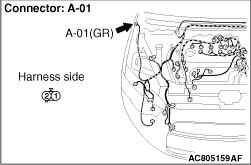

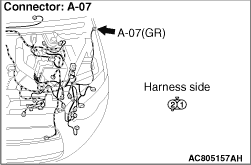

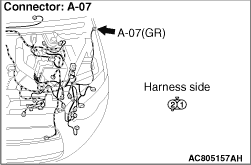

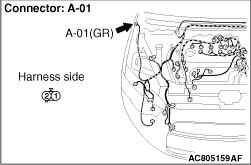

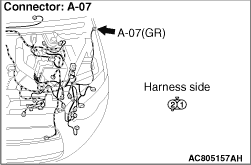

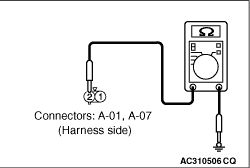

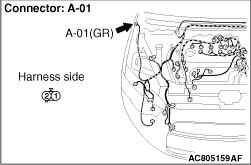

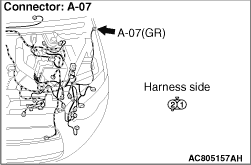

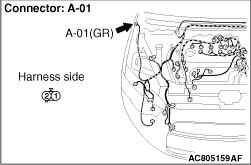

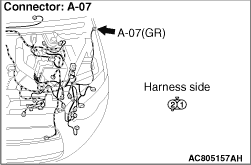

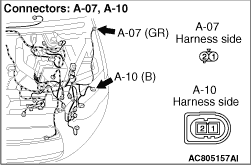

(1)Disconnect the connector, and measure at the wiring harness side.

|

|

(2)Resistance measurement between the defective lamp connector terminal and body earth.

- Resistance between A-07 side turn-signal lamp (LH) connector terminal No.2

and body earth

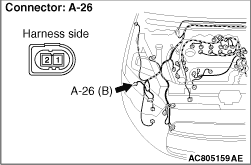

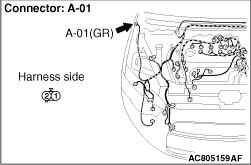

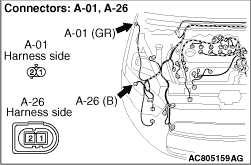

- Resistance between A-01 side turn-signal lamp (RH) connector terminal No.2 and body

earth

OK: Continuity exists (2 Ω or less)

Q.

Is the check result normal?

Go to Step 13. Go to Step 13.

Go to Step 12. Go to Step 12.

|

|

- Check the earth wires for open circuit.

Q.

Is the check result normal?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). ).

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

Q.

Is the check result normal?

Go to Step 14. Go to Step 14.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

| note |

Prior to the wiring harness inspection, check junction block connector B-212, and repair

if necessary.

|

- Check the output lines for open circuit.

Q.

Is the check result normal?

Go to Step 15. Go to Step 15.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

|

Check that the side turn-signal lamps illuminate normally.

|

|

|

Q.

Is the check result normal?

|

|

|

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25. ). Go to Step 25.

|

|

|

|

|

|

Replace the side turn-signal lamp. Go to Step 25. Replace the side turn-signal lamp. Go to Step 25.

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 17. Go to Step 17.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

|

Check the bulb(s) of the defective lamp.

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the bulb(s) of the defective lamp. Go to Step 25. Replace the bulb(s) of the defective lamp. Go to Step 25.

|

|

|

|

|

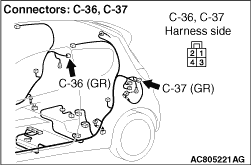

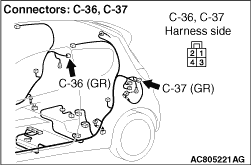

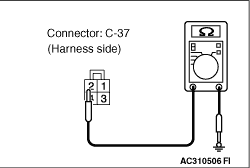

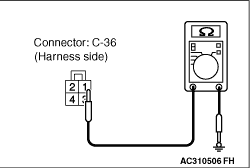

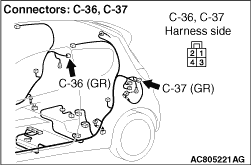

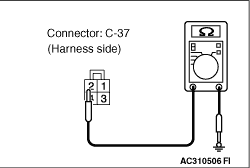

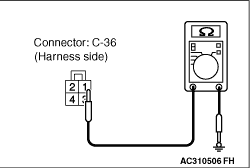

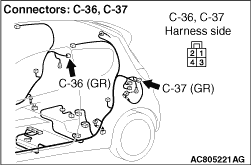

(1)Disconnect the connector, and measure at the wiring harness side.

|

|

(2)Resistance measurement between the defective lamp connector terminal and body earth.

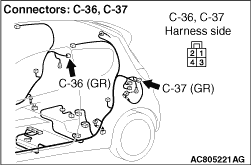

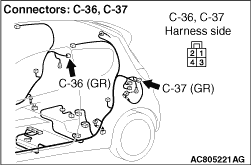

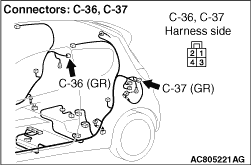

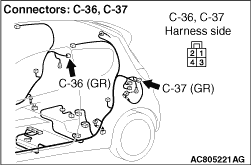

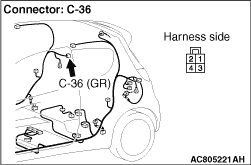

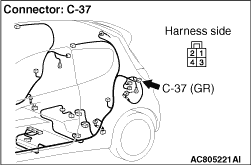

- Resistance between C-37 rear combination lamp (turn: LH) connector terminal No.2 and body

earth

- Resistance between C-36 rear combination lamp (turn: RH) connector terminal No.1 and body

earth

OK: Continuity exists (2 Ω or less)

Q.

Is the check result normal?

Go to Step 20. Go to Step 20.

Go to Step 19. Go to Step 19.

|

|

- Check the earth wires for open circuit.

Q.

Is the check result normal?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25. ). Go to Step 25.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

Q.

Is the check result normal?

Go to Step 21. Go to Step 21.

Repair the defective connector. Go to Step 25. Repair the defective connector. Go to Step 25.

|

|

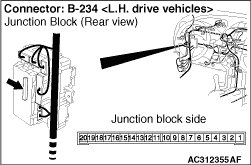

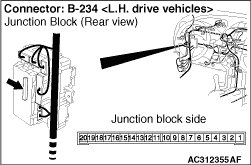

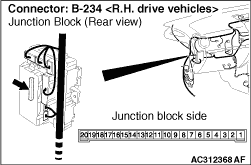

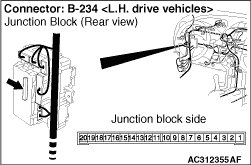

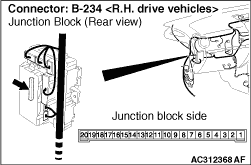

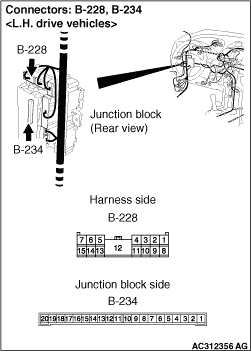

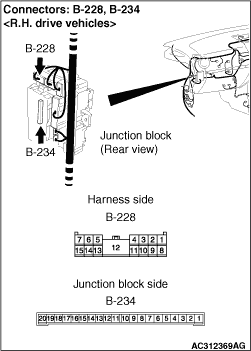

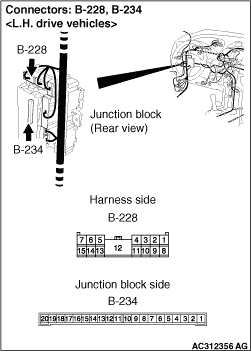

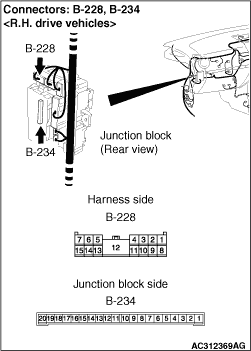

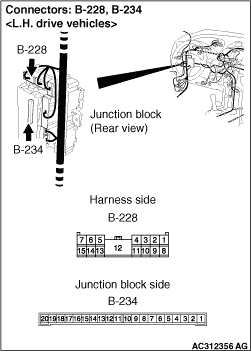

| note |

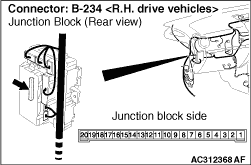

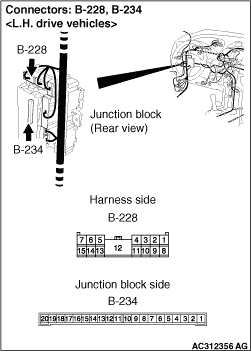

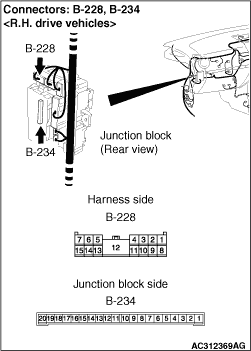

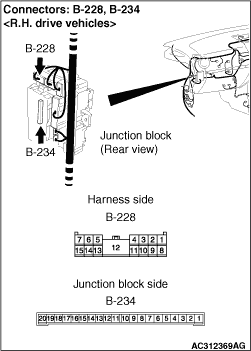

Prior to the wiring harness inspection, check junction block connector B-228, and repair

if necessary.

|

- Check the output lines for open circuit.

Q.

Is the check result normal?

Go to Step 22. Go to Step 22.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

|

Check that the rear turn-signal lamps illuminate normally.

|

|

|

Q.

Is the check result normal?

|

|

|

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25. ). Go to Step 25.

|

|

|

|

|

|

Replace the rear combination lamp. Go to Step 25. Replace the rear combination lamp. Go to Step 25.

|

|

|

|

|

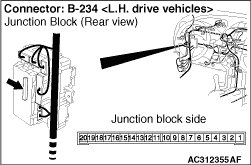

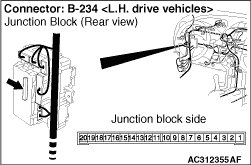

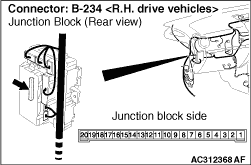

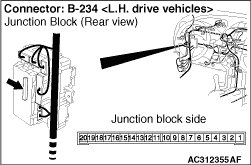

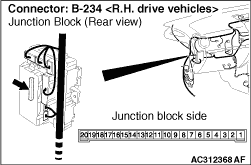

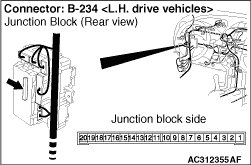

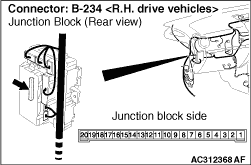

| note |

Prior to the wiring harness inspection, check junction block connectors B-212 and B-228,

and repair if necessary.

|

- Check the output lines for short circuit.

Q.

Is the check result normal?

Go to Step 25. Go to Step 25.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

| note |

Prior to the wiring harness inspection, check junction block connectors B-212 and B-228,

and repair if necessary.

|

- Check the output lines for short circuit.

Q.

Is the check result normal?

Go to Step 25. Go to Step 25.

Repair the wiring harness. Go to Step 25. Repair the wiring harness. Go to Step 25.

|

|

|

Check if diagnosis code No.B1740 or B1741 is set.

|

|

|

Q.

Is the diagnosis code set?

|

|

|

Replace the ETACS-ECU. Then perform the variant coding and write the VIN data

(Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding Replace the ETACS-ECU. Then perform the variant coding and write the VIN data

(Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

: Go to Step 2.

: Go to Step 2.

: Go to Step 2.

: Go to Step 2. : Go to Step 9.

: Go to Step 9. : Go to Step 16.

: Go to Step 16. : Go to Step 23.

: Go to Step 23. : Go to Step 24.

: Go to Step 24.

Go to Step 3.

Go to Step 3. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25. Go to Step 4.

Go to Step 4. Replace the bulb(s) of the defective lamp. Go to Step 25.

Replace the bulb(s) of the defective lamp. Go to Step 25.

Go to Step 7.

Go to Step 7. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25.

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25.

). Go to Step 25. Replace the front combination lamp. Go to Step 25.

Replace the front combination lamp. Go to Step 25.

Go to Step 10.

Go to Step 10. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25. Go to Step 11.

Go to Step 11. Replace the bulb(s) of the defective lamp. Go to Step 25.

Replace the bulb(s) of the defective lamp. Go to Step 25.

Go to Step 13.

Go to Step 13. Go to Step 12.

Go to Step 12.

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ).

). Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25.

Go to Step 14.

Go to Step 14. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25.

Go to Step 15.

Go to Step 15. Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25.

). Go to Step 25. Replace the side turn-signal lamp. Go to Step 25.

Replace the side turn-signal lamp. Go to Step 25.

Go to Step 17.

Go to Step 17. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25. Go to Step 18.

Go to Step 18. Replace the bulb(s) of the defective lamp. Go to Step 25.

Replace the bulb(s) of the defective lamp. Go to Step 25.

Go to Step 20.

Go to Step 20. Go to Step 19.

Go to Step 19.

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25.

). Go to Step 25. Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25.

Go to Step 21.

Go to Step 21. Repair the defective connector. Go to Step 25.

Repair the defective connector. Go to Step 25.

Go to Step 22.

Go to Step 22. Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to use Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). Go to Step 25.

). Go to Step 25. Replace the rear combination lamp. Go to Step 25.

Replace the rear combination lamp. Go to Step 25.

Go to Step 25.

Go to Step 25. Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25.

Go to Step 25.

Go to Step 25. Repair the wiring harness. Go to Step 25.

Repair the wiring harness. Go to Step 25. Replace the ETACS-ECU. Then perform the variant coding and write the VIN data

(Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding

Replace the ETACS-ECU. Then perform the variant coding and write the VIN data

(Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ).

). The procedure is complete.

The procedure is complete.