|

| caution |

The strand end of the twist wire should be within 10 cm from

the connector. For details refer to  . .

|

|

|

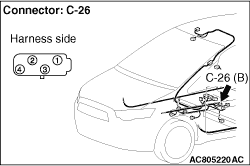

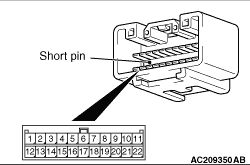

When checking the joint connector, ensure that its wiring harness side and its short pins

are not damaged.

Q.

Are the check results normal?

Go to Step 2. Go to Step 2.

Repair a defective connector or replace the joint connector. Repair a defective connector or replace the joint connector.

|

|

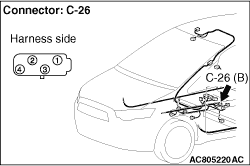

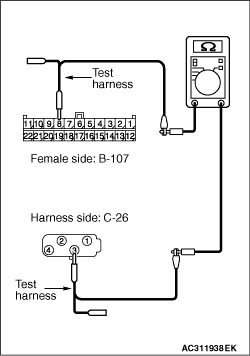

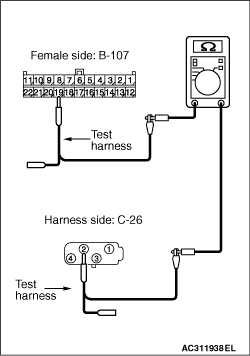

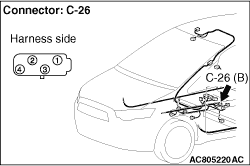

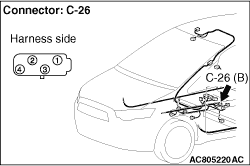

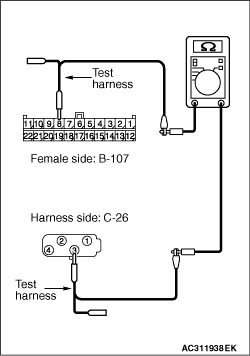

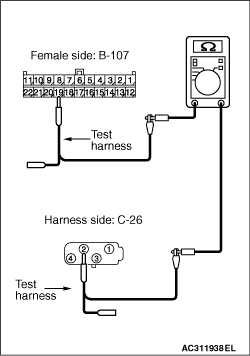

(1)Disconnect the joint connector (CAN2) and the G and yaw rate sensor connector, and measure

at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery

terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

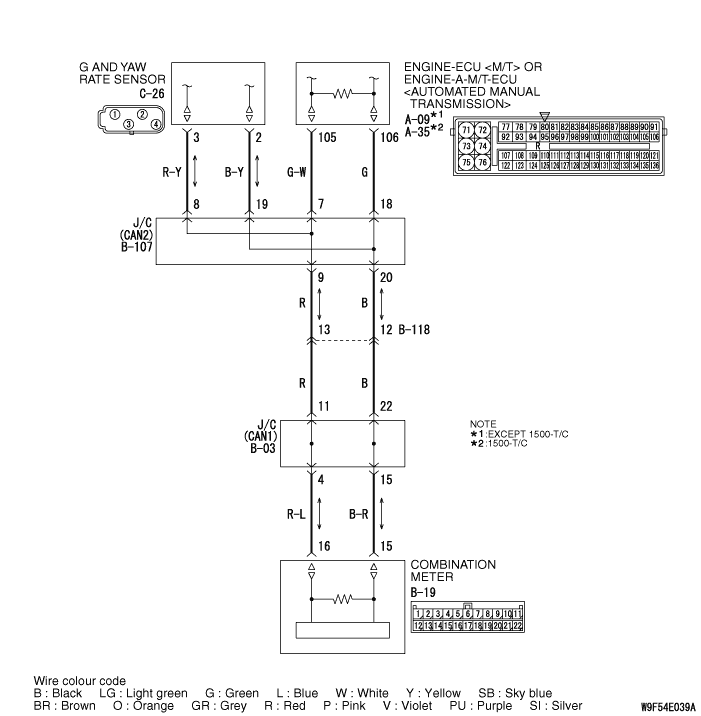

(4)Continuity between B-107 joint connector (CAN2) terminal No.8 and C-26 G and yaw rate

sensor connector terminal No.3

OK: 2 ohms or less

|

|

(5)Continuity between B-107 joint connector (CAN2) terminal No.19 and C-26 G and yaw rate

sensor connector terminal No.2

OK: 2 ohms or less

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

Q.

Are the check results normal?

<All the resistances measure 2 Ω or less> Power supply

to the G and yaw rate sensor may be suspected. Diagnose the TCL/ASC system. Refer to <All the resistances measure 2 Ω or less> Power supply

to the G and yaw rate sensor may be suspected. Diagnose the TCL/ASC system. Refer to  . .

<Either or all of the voltages measure more than 2 Ω> Repair

the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector. <Either or all of the voltages measure more than 2 Ω> Repair

the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

|

.

.

<All the resistances measure 2 Ω or less> Power supply

to the G and yaw rate sensor may be suspected. Diagnose the TCL/ASC system. Refer to

<All the resistances measure 2 Ω or less> Power supply

to the G and yaw rate sensor may be suspected. Diagnose the TCL/ASC system. Refer to  .

. <Either or all of the voltages measure more than 2 Ω> Repair

the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

<Either or all of the voltages measure more than 2 Ω> Repair

the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.