|

| caution |

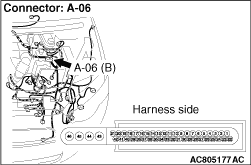

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 2. Go to Step 2.

Repair the defective connector. Repair the defective connector.

|

|

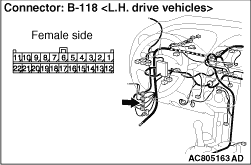

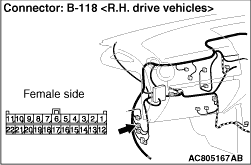

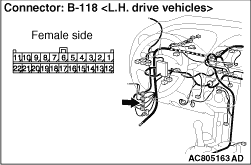

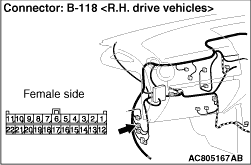

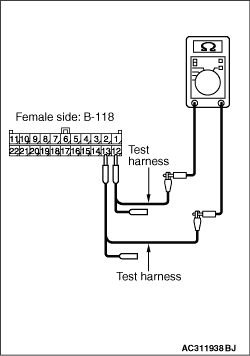

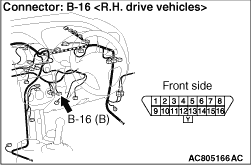

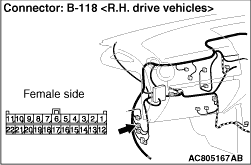

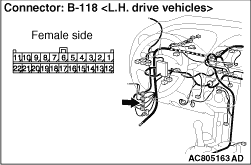

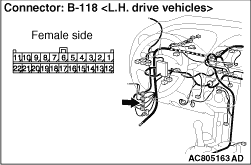

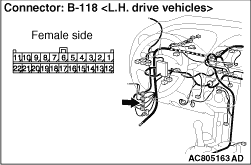

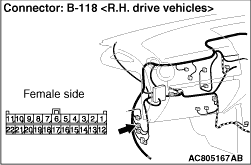

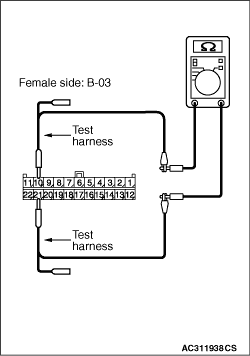

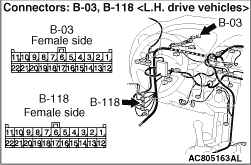

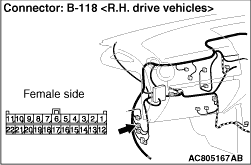

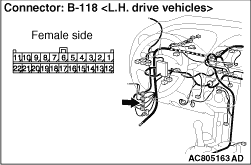

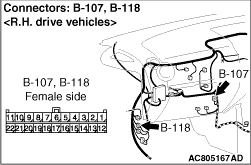

(1)Disconnect the connector, and measure at its female-side intermediate connector (at the front wiring harness side).

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Resistance between B-118 intermediate connector terminal Nos.12 and 13

OK: 120 ± 20 Ω

Q.

Is the check result normal?

<Within 120 ± 20 Ω> Go to Step 3. <Within 120 ± 20 Ω> Go to Step 3.

<Not within 120 ± 20 Ω> Go to Step 20. <Not within 120 ± 20 Ω> Go to Step 20.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

|

|

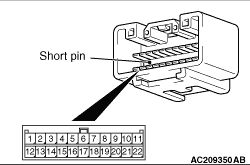

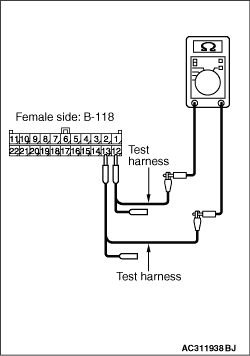

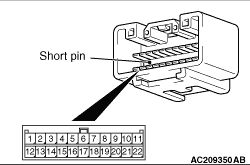

When checking the joint connector, ensure that its wiring harness side and its short pins are not damaged.

Q.

Is the check result normal?

Go to Step 4. Go to Step 4.

Repair a defective connector or replace the joint connector. Repair a defective connector or replace the joint connector.

|

|

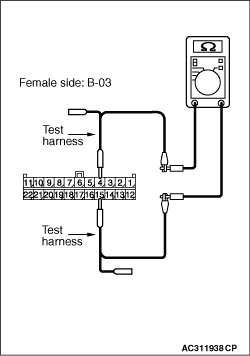

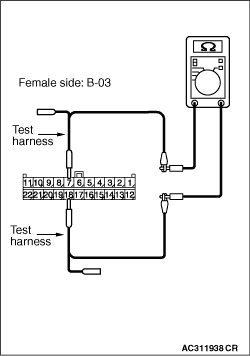

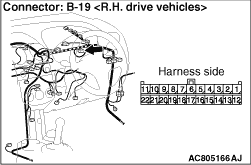

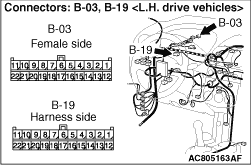

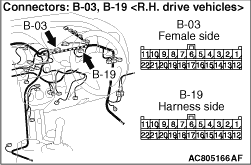

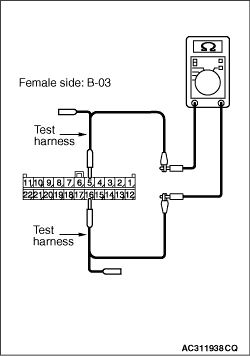

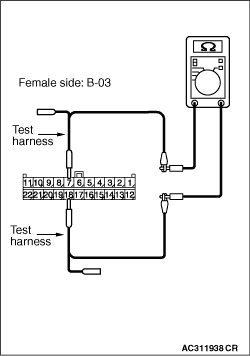

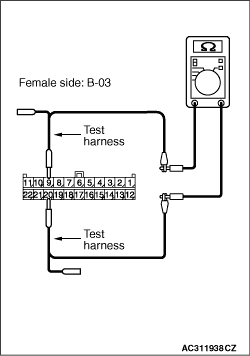

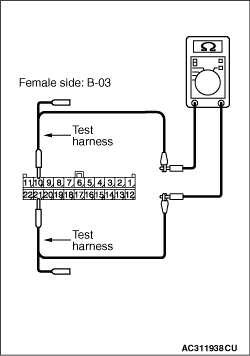

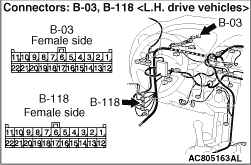

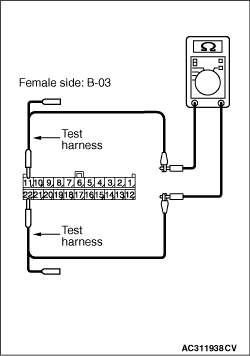

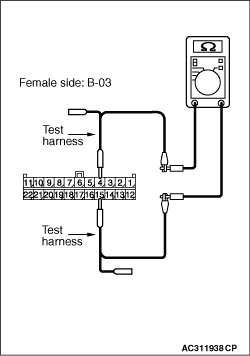

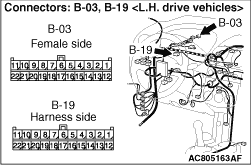

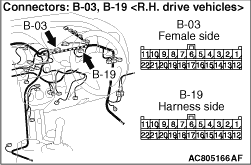

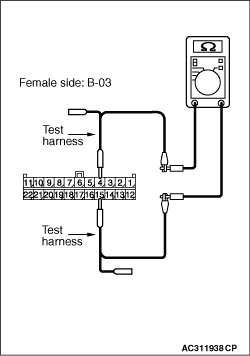

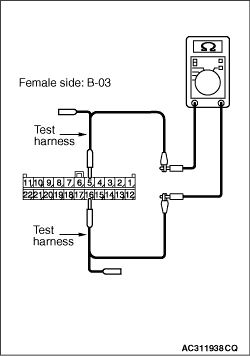

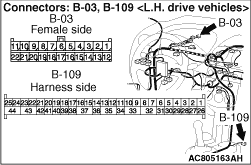

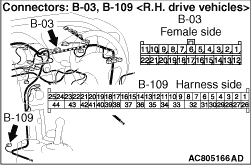

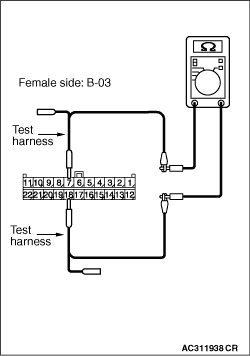

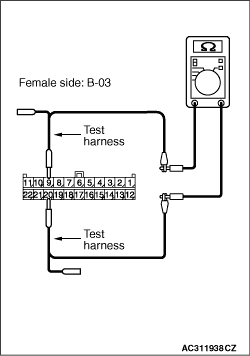

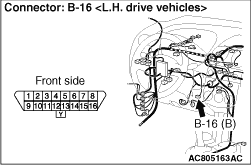

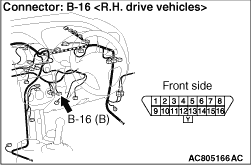

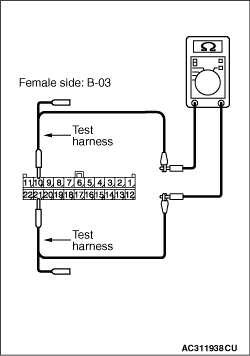

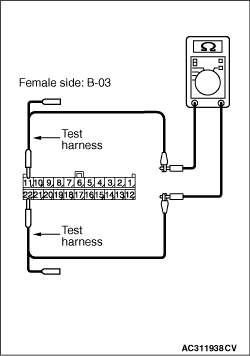

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Resistance between B-03 joint connector (CAN1) terminal Nos.4 and 15

OK: 120 ± 20 Ω

|

|

(5)Resistance between B-03 joint connector (CAN1) terminal Nos.5 and 16

OK: 1 kΩ or more

|

|

(6)Resistance between B-03 joint connector (CAN1) terminal Nos.7 and 18

OK: 1 kΩ or more

|

|

(7)Resistance between B-03 joint connector (CAN1) terminal Nos.9 and 20

OK: 1 kΩ or more

|

|

(8)Resistance between B-03 joint connector (CAN1) terminal Nos.10 and 21

OK: 1 kΩ or more

Q.

Are the check results normal?

YES <all of the measurement results are within the normal value> : Go to Step 19. : Go to Step 19.

NO <The resistance between terminal Nos.4 and 15 is less than 120 ± 20 Ω> : Go to Step 5. : Go to Step 5.

NO <The resistance between terminal Nos.5 and 16 is less than 1 kΩ> : Go to Step 8. : Go to Step 8.

NO <The resistance between terminal Nos.7 and 18 is less than 1 kΩ> : Go to Step 11. : Go to Step 11.

NO <The resistance between terminal Nos.9 and 20 is less than 1 kΩ> : Go to Step 14. : Go to Step 14.

NO <The resistance between terminal Nos.10 and 21 is less than 1 kΩ> : Go to Step 17. : Go to Step 17.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 6. Go to Step 6.

Repair the defective connector. Repair the defective connector.

|

|

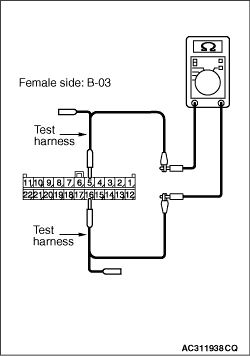

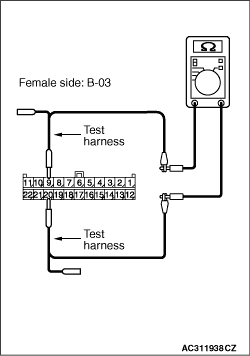

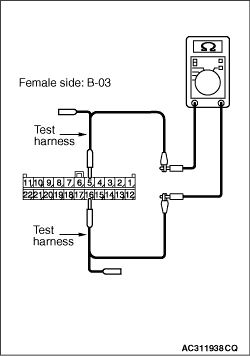

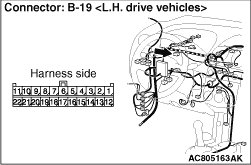

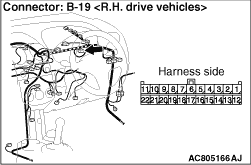

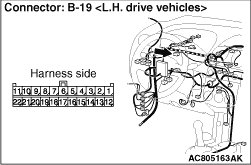

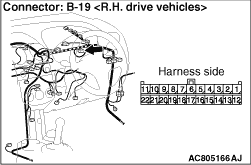

(1)Disconnect the joint connector (CAN1) and the combination meter connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.4 and 15

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 7. <More than 2 Ω> Go to Step 7.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the combination meter connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

|

|

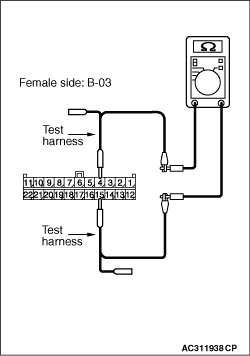

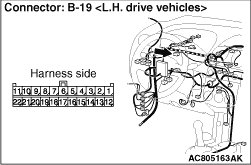

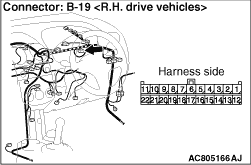

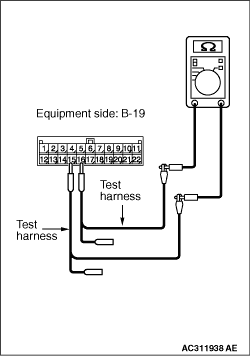

(1)Remove the combination meter, and measure at the equipment side.

|

|

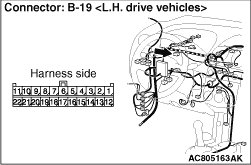

(2)Resistance between B-19 combination meter connector terminal Nos.15 and 16

OK: 120 ± 20 Ω

Q.

Is the check result normal?

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Not within 120 ± 20 Ω> Replace the combination meter. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding <Not within 120 ± 20 Ω> Replace the combination meter. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 9. Go to Step 9.

Repair the defective connector. Repair the defective connector.

|

|

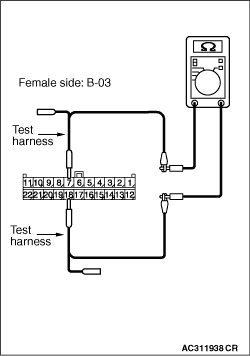

(1)Disconnect the joint connector (CAN1) and the ETACS-ECU connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.5 and 16

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 10. <More than 2 Ω> Go to Step 10.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the ETACS-ECU connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the ETACS-ECU connector.

|

|

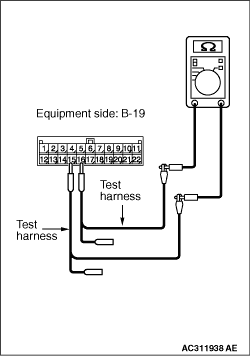

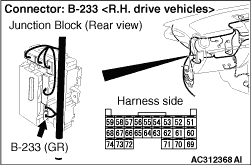

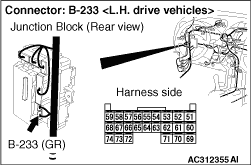

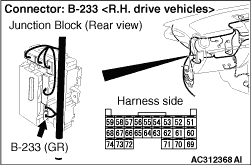

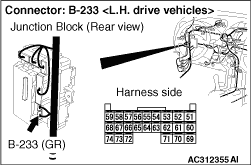

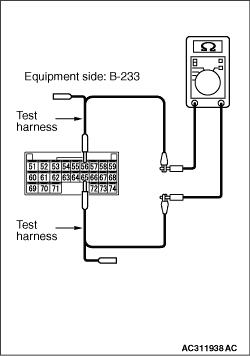

(1)Remove the ETACS-ECU, and measure at the equipment side.

|

|

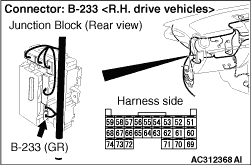

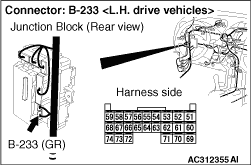

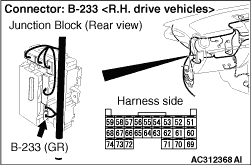

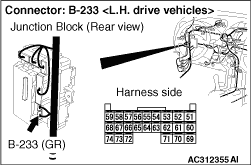

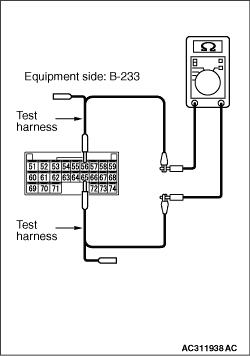

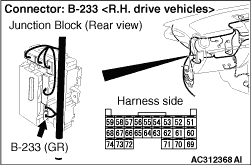

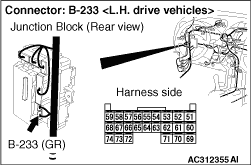

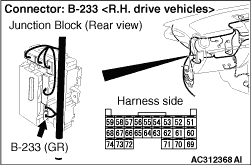

(2)Resistance between B-233 ETACS-ECU connector terminal Nos.56 and 65

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the ETACS-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding <Less than 1 kΩ> Replace the ETACS-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 12. Go to Step 12.

Repair the defective connector. Repair the defective connector.

|

|

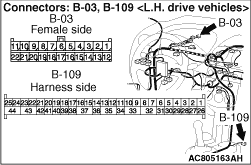

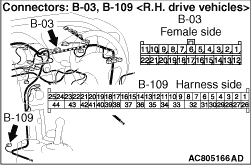

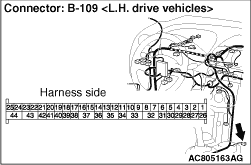

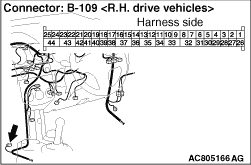

(1)Disconnect the joint connector (CAN1) and the SRS-ECU connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.7 and 18

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 13. <More than 2 Ω> Go to Step 13.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the SRS-ECU connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the SRS-ECU connector.

|

|

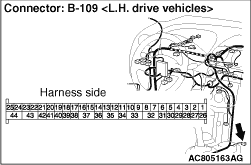

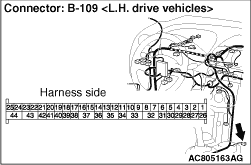

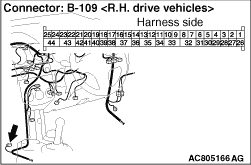

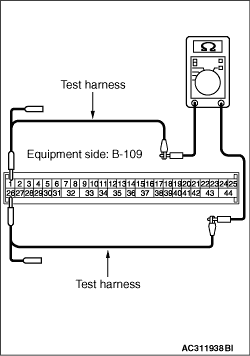

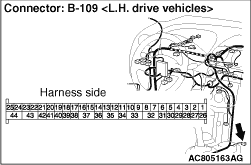

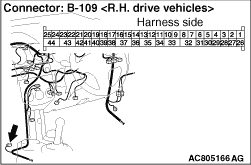

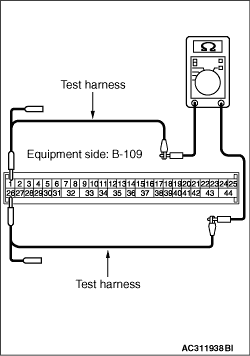

(1)Remove the SRS-ECU, and measure at the equipment side.

|

|

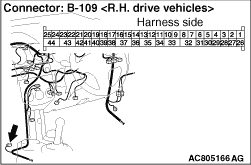

(2)Resistance between B-109 SRS-ECU connector terminal Nos.26 and 1

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the SRS-ECU. <Less than 1 kΩ> Replace the SRS-ECU.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 15. Go to Step 15.

Repair the defective connector. Repair the defective connector.

|

|

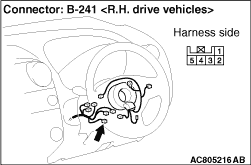

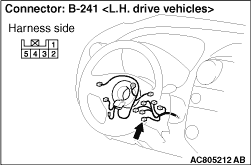

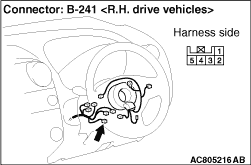

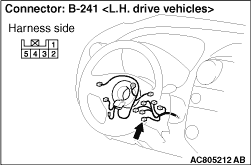

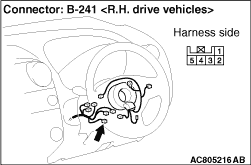

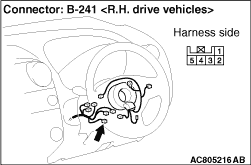

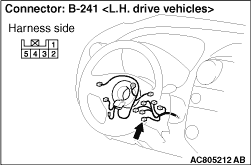

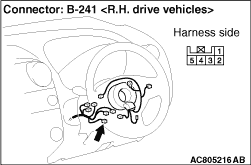

(1)Disconnect the joint connector (CAN1) and the steering wheel sensor connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.9 and 20

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 16. <More than 2 Ω> Go to Step 16.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the steering wheel sensor connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the steering wheel sensor connector.

|

|

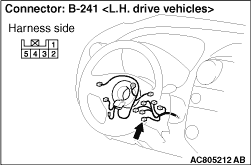

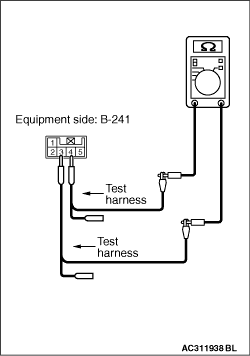

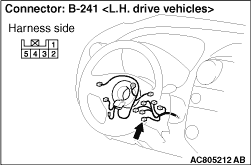

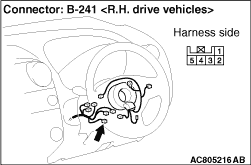

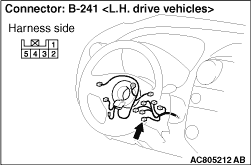

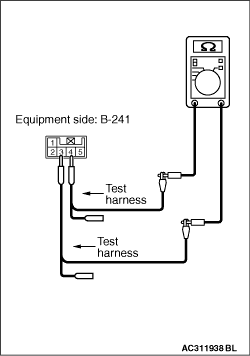

(1)Remove the steering wheel sensor, and measure at the equipment side.

|

|

(2)Resistance between B-241 steering wheel sensor connector terminal Nos.3 and 4

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the steering wheel sensor. <Less than 1 kΩ> Replace the steering wheel sensor.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 18. Go to Step 18.

Repair the defective connector. Repair the defective connector.

|

|

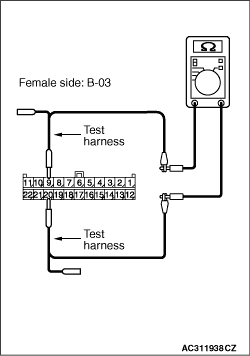

(1)Disconnect the joint connector (CAN1), and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.10 and 21

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the diagnosis connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the diagnosis connector.

|

|

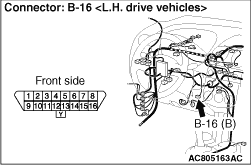

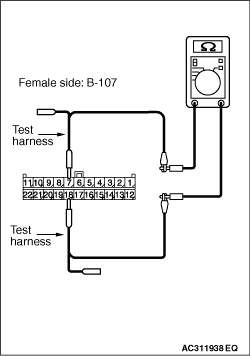

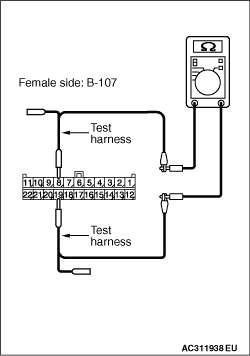

(1)Disconnect the joint connector (CAN1) and the intermediate connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-03 joint connector (CAN1) terminal Nos.11 and 22

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the intermediate connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the intermediate connector.

|

|

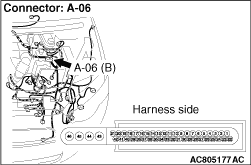

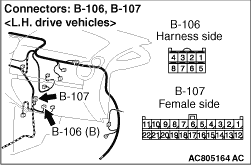

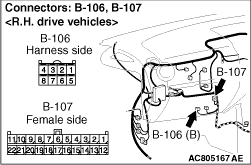

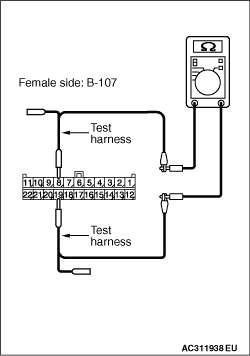

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

When checking the joint connector, ensure that its wiring harness side is not damaged.

Q.

Is the check result normal?

Go to Step 21. Go to Step 21.

Repair a defective connector or replace the joint connector (front wiring harness assembly). Repair a defective connector or replace the joint connector (front wiring harness assembly).

|

|

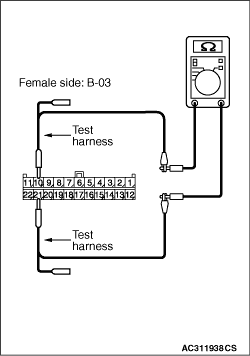

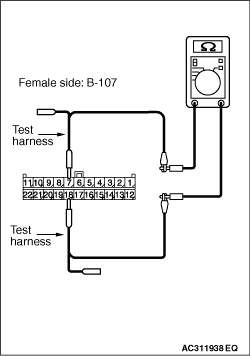

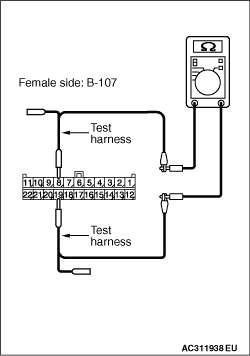

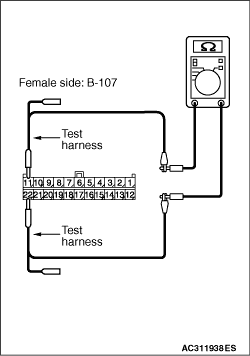

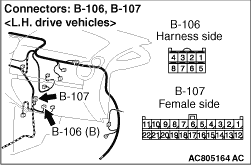

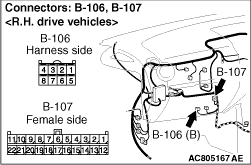

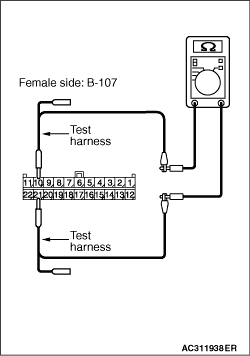

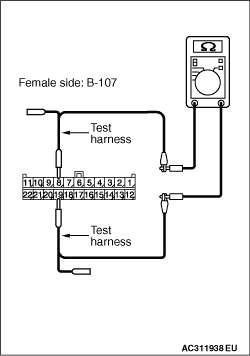

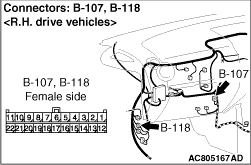

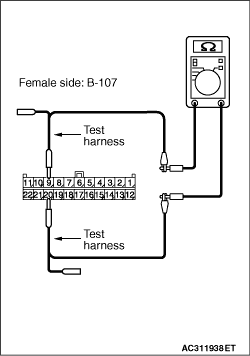

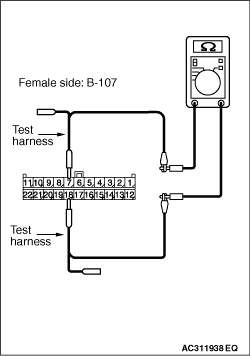

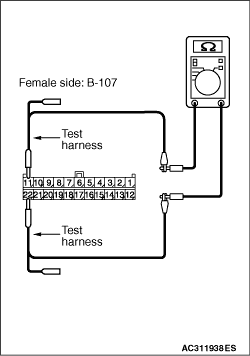

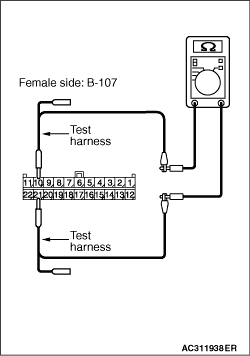

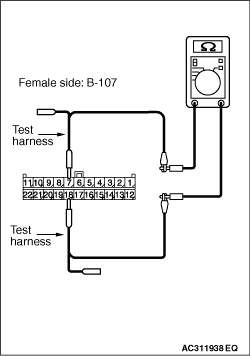

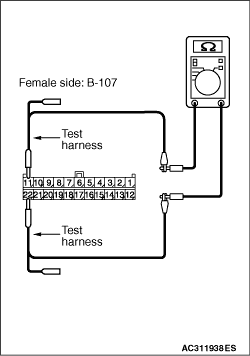

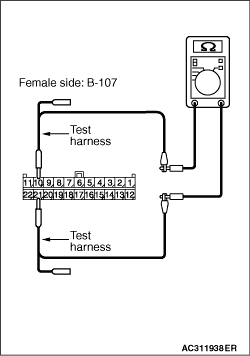

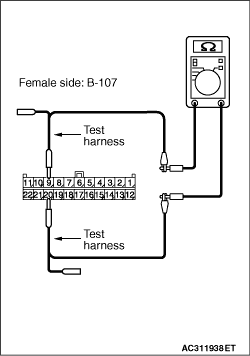

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

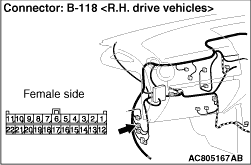

(4)Resistance between B-107 joint connector (CAN2) terminal Nos.7 and 18

OK: 120 ± 20 Ω

|

|

(5)Resistance between B-107 joint connector (CAN2) terminal Nos.11 and 22

OK: 1 kΩ or more

|

|

(6)Resistance between B-107 joint connector (CAN2) terminal Nos.10 and 21

OK: 1 kΩ or more

|

|

(7)Resistance between B-107 joint connector (CAN2) terminal Nos.8 and 19

OK: 1 kΩ or more

Q.

Are the check results normal?

YES <all of the measurement results are within the normal value> : Go to Step 34. : Go to Step 34.

NO <The resistance between terminal Nos.7 and 18 is less than 120 ± 20 Ω> : Go to Step 22. : Go to Step 22.

NO <The resistance between terminal Nos.11 and 22 is less than 1 kΩ> : Go to Step 25. : Go to Step 25.

NO <The resistance between terminal Nos.10 and 21 is less than 1 kΩ> : Go to Step 28. : Go to Step 28.

NO <The resistance between terminal Nos.8 and 19 is less than 1 kΩ> : Go to Step 31. : Go to Step 31.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 23. Go to Step 23.

Repair the defective connector. Repair the defective connector.

|

|

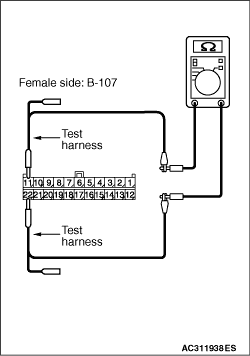

(1)Disconnect the joint connector (CAN2) and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-107 joint connector (CAN2) terminal Nos.7 and 18

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 24. <More than 2 Ω> Go to Step 24.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

|

|

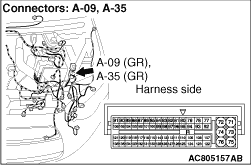

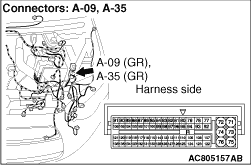

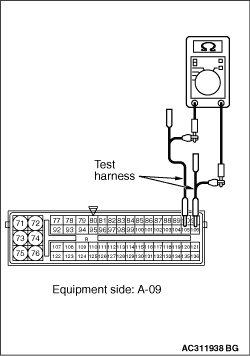

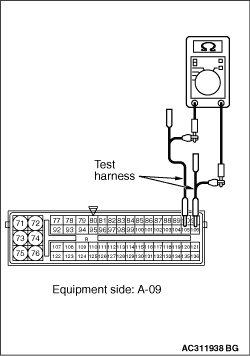

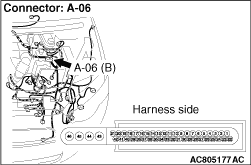

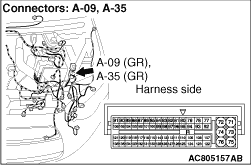

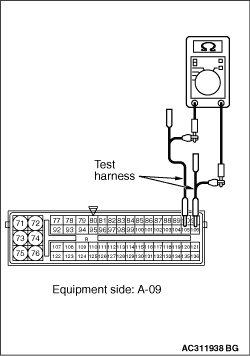

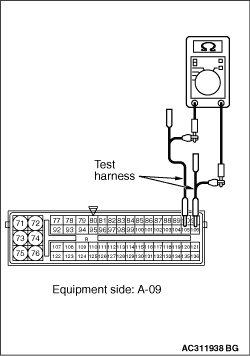

(1)Remove the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission>, and measure at the equipment side.

|

|

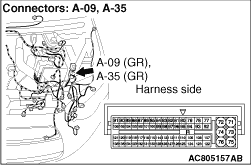

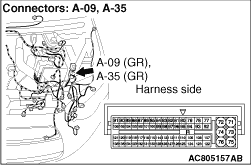

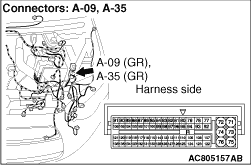

(2)Resistance at A-09 engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector terminal Nos.105 and 106 <except 1500-T/C>

OK: 120 ± 20 Ω

|

|

(3)A-35 engine-ECU <M/T> connector terminal Nos.105 and 106 <1500-T/C>

OK: 120 ± 20 Ω

Q.

Is the check result normal?

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Not within 120 ± 20 Ω> Replace the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission>. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding <Not within 120 ± 20 Ω> Replace the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission>. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 26. Go to Step 26.

Repair the defective connector. Repair the defective connector.

|

|

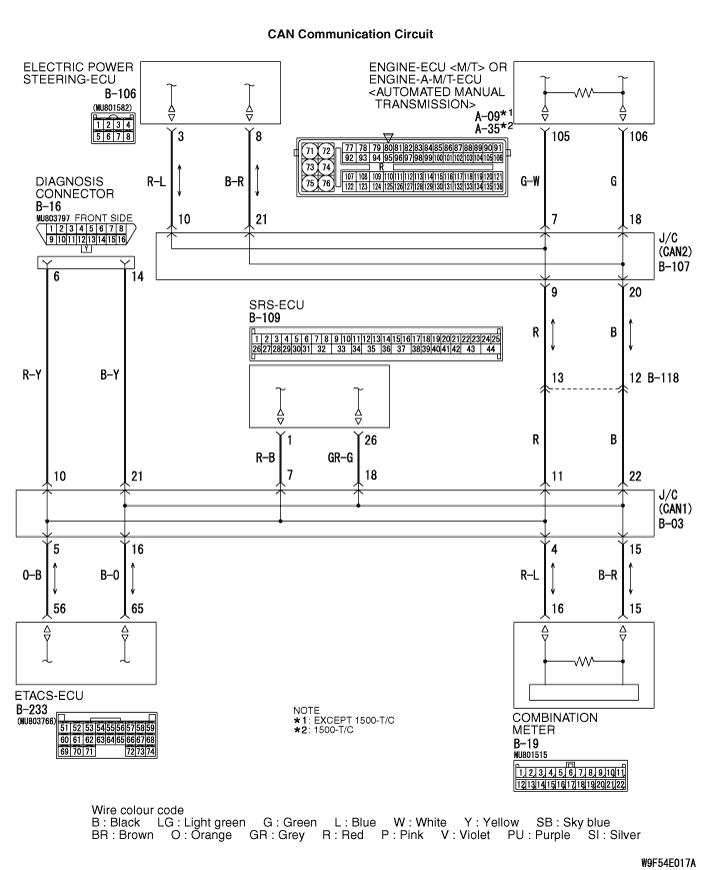

(1)Disconnect the joint connector (CAN2) and the TCL/ASC-ECU connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-107 joint connector (CAN2) terminal Nos.11 and 22

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 27. <More than 2 Ω> Go to Step 27.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

|

|

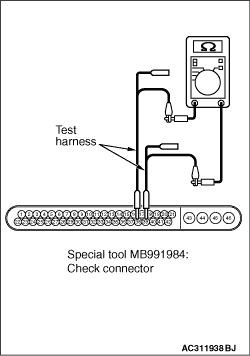

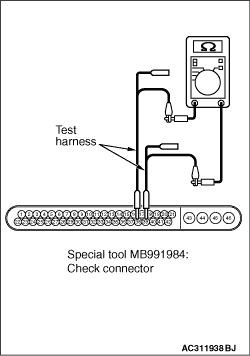

(1)Connect special tool MB991984 to the TCL/ASC-ECU connector, and measure by using the check connector (connect the ECU side only).

|

|

(2)Resistance between special tool MB991984 check connector terminal Nos.38 and 39.

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the TCL/ASC-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding <Less than 1 kΩ> Replace the TCL/ASC-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 29. Go to Step 29.

Repair the defective connector. Repair the defective connector.

|

|

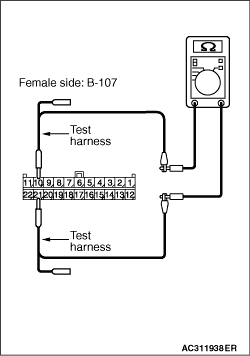

(1)Disconnect the joint connector (CAN2) and the electric power steering-ECU connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-107 joint connector (CAN2) terminal Nos.10 and 21

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 30. <More than 2 Ω> Go to Step 30.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

|

|

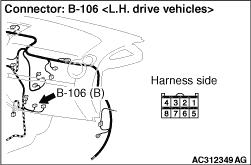

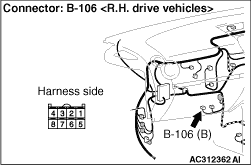

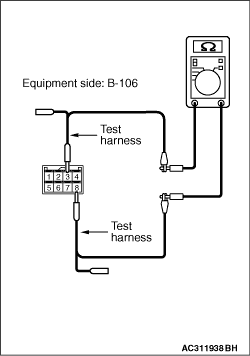

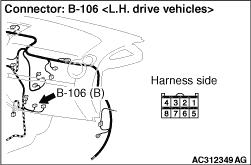

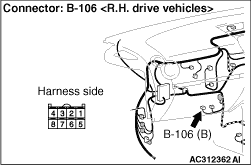

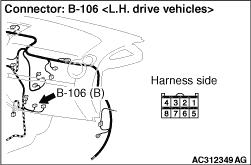

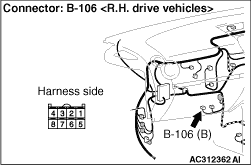

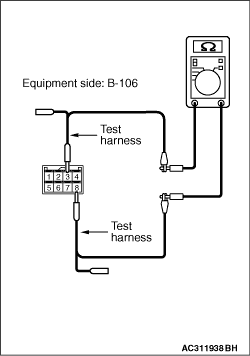

(1)Remove the electric power steering-ECU, and measure at the equipment side.

|

|

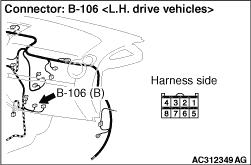

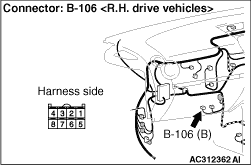

(2)Resistance at B-106 electric power steering-ECU connector terminal Nos.3 and 8

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the electric power steering-ECU. <Less than 1 kΩ> Replace the electric power steering-ECU.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 32. Go to Step 32.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the G and yaw rate sensor connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Continuity between B-107 joint connector (CAN2) terminal Nos.8 and 19

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> Go to Step 33. <More than 2 Ω> Go to Step 33.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

|

|

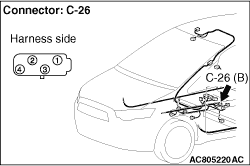

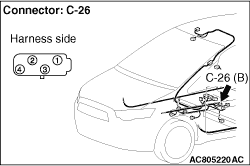

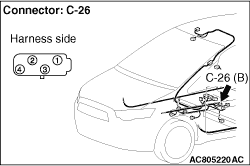

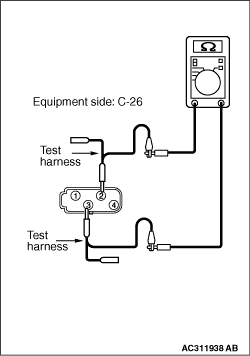

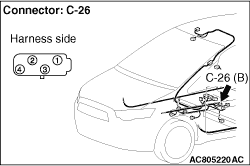

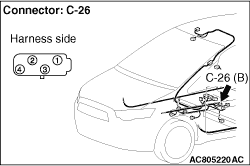

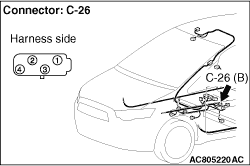

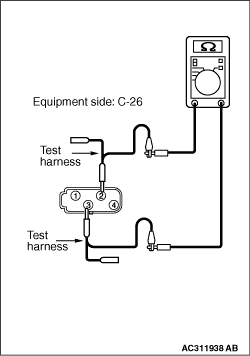

(1)Remove the G and yaw rate sensor, and measure at the equipment side.

|

|

(2)Resistance at C-26 G and yaw rate sensor connector terminal Nos.2 and 3

OK: 1 kΩ or more

Q.

Is the check result normal?

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<Less than 1 kΩ> Replace the electric power steering-ECU. <Less than 1 kΩ> Replace the electric power steering-ECU.

|

|

(1)Disconnect the joint connector (CAN2) and the intermediate connector, and measure at the wiring harness side.

(2)Ignition switch: OFF (LOCK)

(3)

| caution |

When measuring the resistance, disconnect the negative battery terminal. For details refer to  . .

|

Ensure that the negative battery terminal is disconnected.

|

|

(4)Measure the continuity between B-107 joint connector (CAN2) terminal Nos.9 and 20.

OK: More than 2 Ω

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the intermediate connector. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the intermediate connector.

|

.

. Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

<Within 120 ± 20 Ω> Go to Step 3.

<Within 120 ± 20 Ω> Go to Step 3. <Not within 120 ± 20 Ω> Go to Step 20.

<Not within 120 ± 20 Ω> Go to Step 20.

Go to Step 4.

Go to Step 4. Repair a defective connector or replace the joint connector.

Repair a defective connector or replace the joint connector.

: Go to Step 19.

: Go to Step 19. : Go to Step 5.

: Go to Step 5. : Go to Step 8.

: Go to Step 8. : Go to Step 11.

: Go to Step 11. : Go to Step 14.

: Go to Step 14. : Go to Step 17.

: Go to Step 17.

Go to Step 6.

Go to Step 6. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 7.

<More than 2 Ω> Go to Step 7. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Not within 120 ± 20 Ω> Replace the combination meter. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding

<Not within 120 ± 20 Ω> Replace the combination meter. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ).

).

Go to Step 9.

Go to Step 9. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 10.

<More than 2 Ω> Go to Step 10. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the ETACS-ECU connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the ETACS-ECU connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the ETACS-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding

<Less than 1 kΩ> Replace the ETACS-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ).

).

Go to Step 12.

Go to Step 12. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 13.

<More than 2 Ω> Go to Step 13. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the SRS-ECU connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the SRS-ECU connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the SRS-ECU.

<Less than 1 kΩ> Replace the SRS-ECU.

Go to Step 15.

Go to Step 15. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 16.

<More than 2 Ω> Go to Step 16. <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the steering wheel sensor connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the steering wheel sensor connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the steering wheel sensor.

<Less than 1 kΩ> Replace the steering wheel sensor.

Go to Step 18.

Go to Step 18. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the diagnosis connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the diagnosis connector.

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the intermediate connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN1) and the intermediate connector.

Go to Step 21.

Go to Step 21. Repair a defective connector or replace the joint connector (front wiring harness assembly).

Repair a defective connector or replace the joint connector (front wiring harness assembly).

: Go to Step 34.

: Go to Step 34. : Go to Step 22.

: Go to Step 22. : Go to Step 25.

: Go to Step 25. : Go to Step 28.

: Go to Step 28. : Go to Step 31.

: Go to Step 31.

Go to Step 23.

Go to Step 23. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 24.

<More than 2 Ω> Go to Step 24. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<Within 120 ± 20 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Not within 120 ± 20 Ω> Replace the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission>. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding

<Not within 120 ± 20 Ω> Replace the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission>. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ).

).

Go to Step 26.

Go to Step 26. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 27.

<More than 2 Ω> Go to Step 27. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the TCL/ASC-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding

<Less than 1 kΩ> Replace the TCL/ASC-ECU. Then perform the variant coding (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ).

).

Go to Step 29.

Go to Step 29. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 30.

<More than 2 Ω> Go to Step 30. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the electric power steering-ECU.

<Less than 1 kΩ> Replace the electric power steering-ECU.

Go to Step 32.

Go to Step 32. Repair the defective connector.

Repair the defective connector.

<More than 2 Ω> Go to Step 33.

<More than 2 Ω> Go to Step 33. <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the TCL/ASC-ECU connector.

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<1 kΩ or more> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <Less than 1 kΩ> Replace the electric power steering-ECU.

<Less than 1 kΩ> Replace the electric power steering-ECU.

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<More than 2 Ω> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the intermediate connector.

<2 Ω or less> Repair the wiring harness between joint connector (CAN2) and the intermediate connector.