|

| caution |

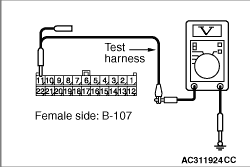

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Are the check results normal?

Go to Step 2. Go to Step 2.

Repair the defective connector. Repair the defective connector.

|

|

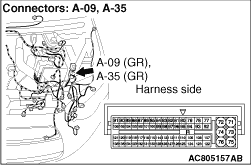

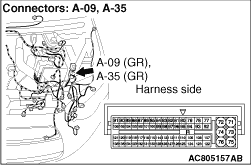

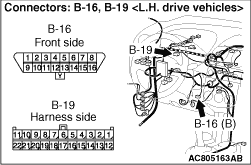

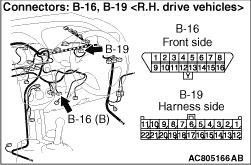

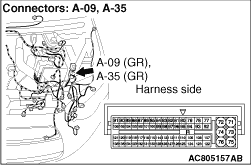

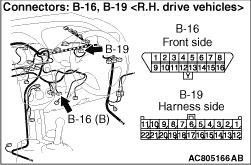

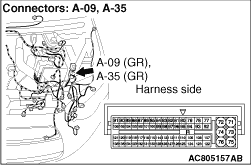

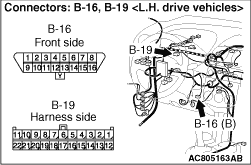

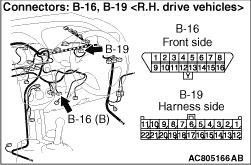

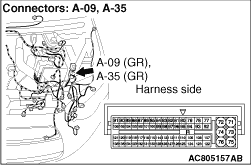

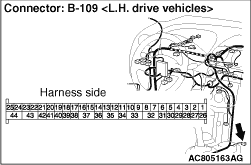

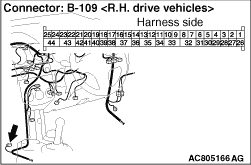

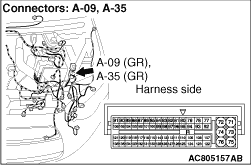

(1)Disconnect the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector and the combination meter connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

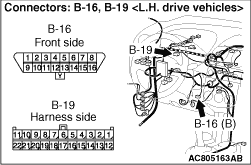

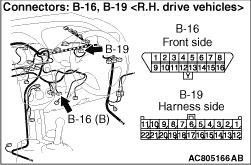

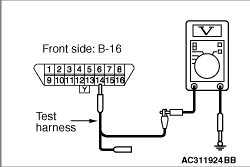

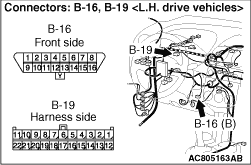

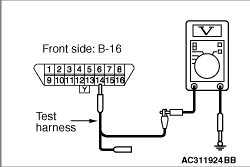

(3)Voltage between B-16 diagnosis connector terminal No.14 and body earth

OK: 4.0 V or less

|

|

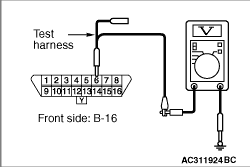

(4)Voltage between B-16 diagnosis connector terminal No.6 and body earth

OK: 4.0 V or less

(5)Disconnect the negative battery terminal.

Q.

Are the check results normal?

YES <all of the measurement results show 4.0 V or less> : It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

NO <The voltage between terminal No.14 and body earth is more than 4.0 V> : Go to Step 3. : Go to Step 3.

NO <The voltage between terminal No.6 and body earth is more than 4.0 V> : Go to Step 28. : Go to Step 28.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 4. Go to Step 4.

Repair the defective connector. Repair the defective connector.

|

|

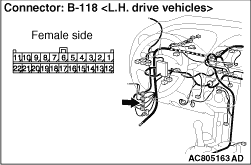

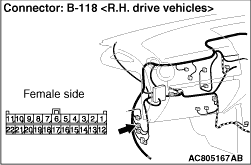

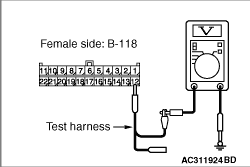

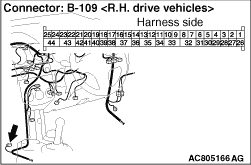

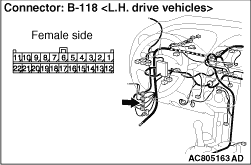

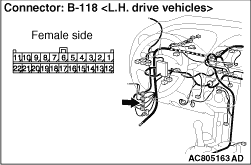

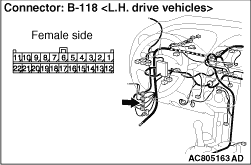

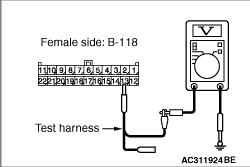

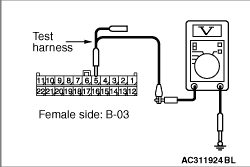

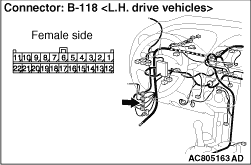

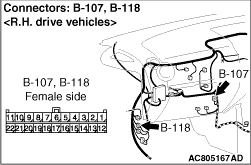

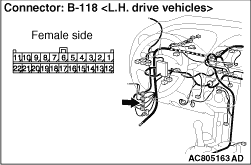

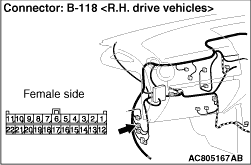

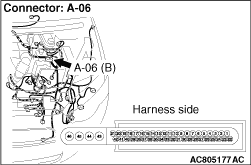

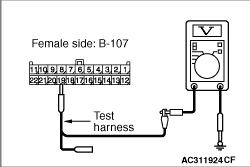

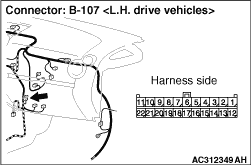

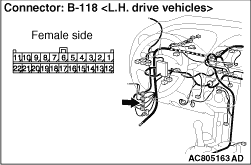

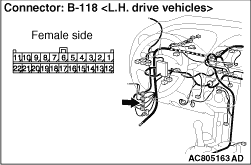

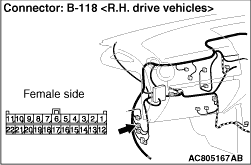

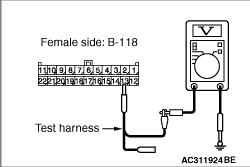

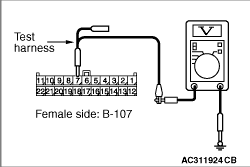

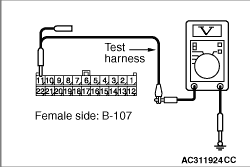

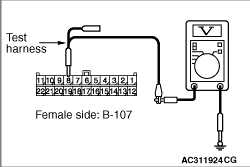

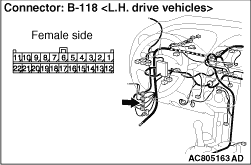

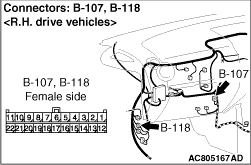

(1)Disconnect the connector, and measure at its female-side intermediate connector (at the front wiring harness side).

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-118 intermediate connector terminal No.12 and body earth

OK: 4.0 V or less

Q.

Is the check result normal?

<4.0 V or less> Go to Step 5. <4.0 V or less> Go to Step 5.

<more than 4.0 V> Go to Step 18. <more than 4.0 V> Go to Step 18.

|

|

| caution |

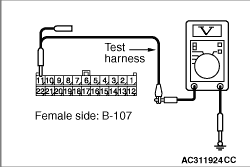

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

|

|

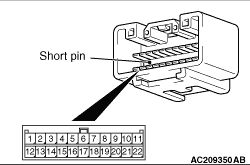

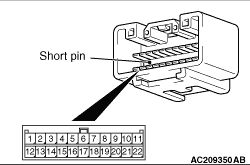

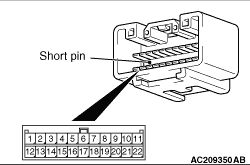

When checking the joint connector, ensure that its wiring harness side and its short pins are not damaged.

Q.

Is the check result normal?

Go to Step 6. Go to Step 6.

Repair a defective connector or replace the joint connector. Repair a defective connector or replace the joint connector.

|

|

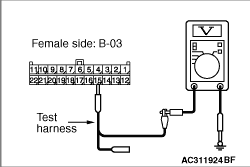

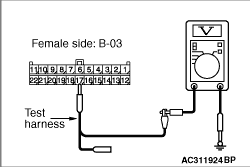

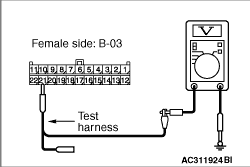

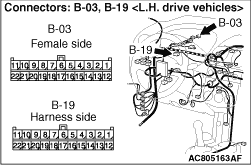

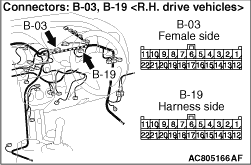

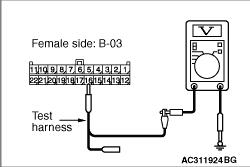

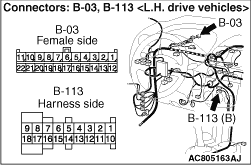

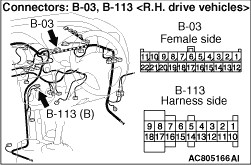

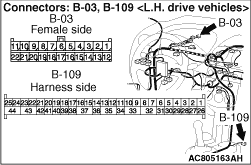

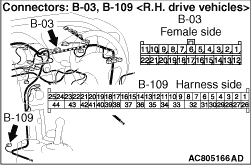

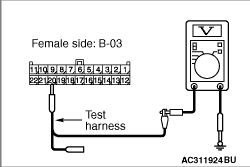

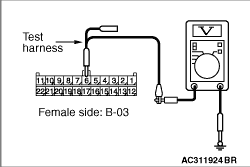

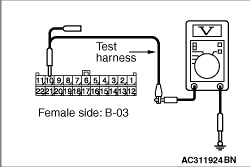

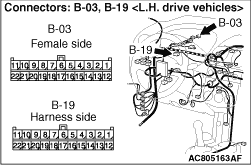

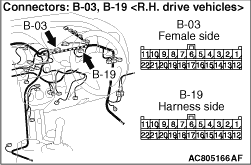

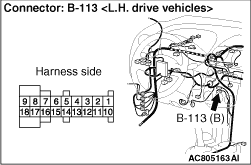

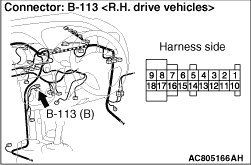

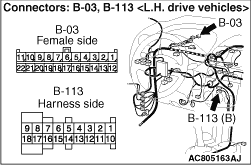

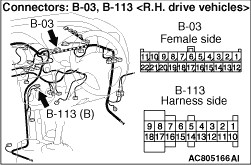

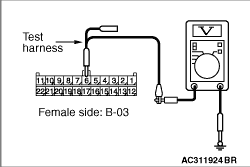

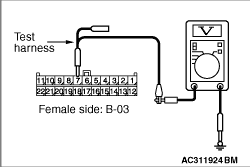

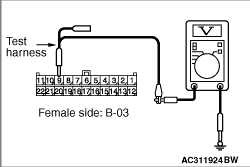

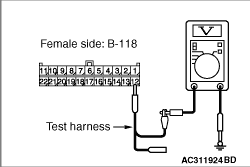

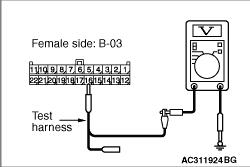

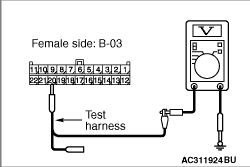

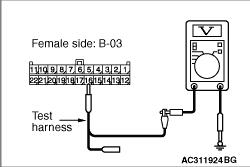

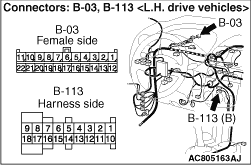

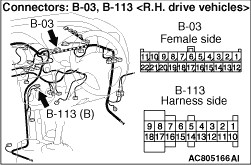

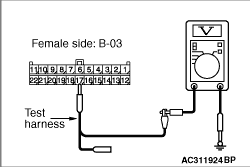

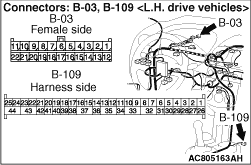

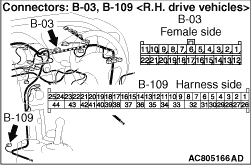

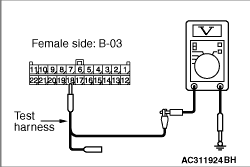

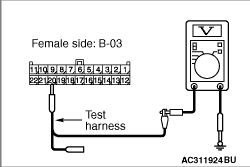

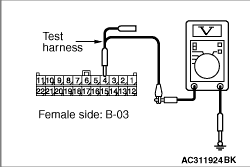

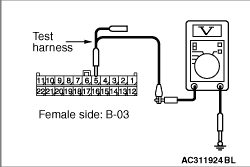

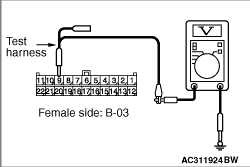

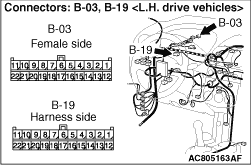

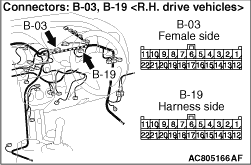

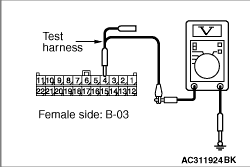

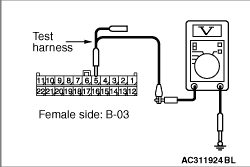

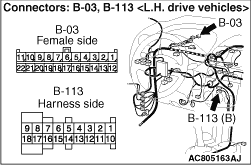

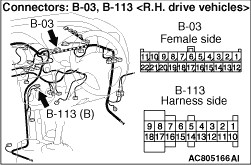

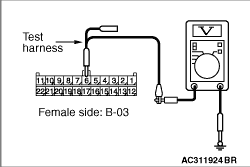

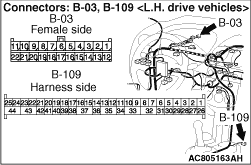

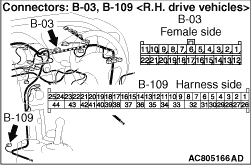

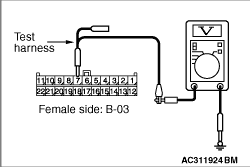

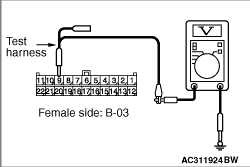

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

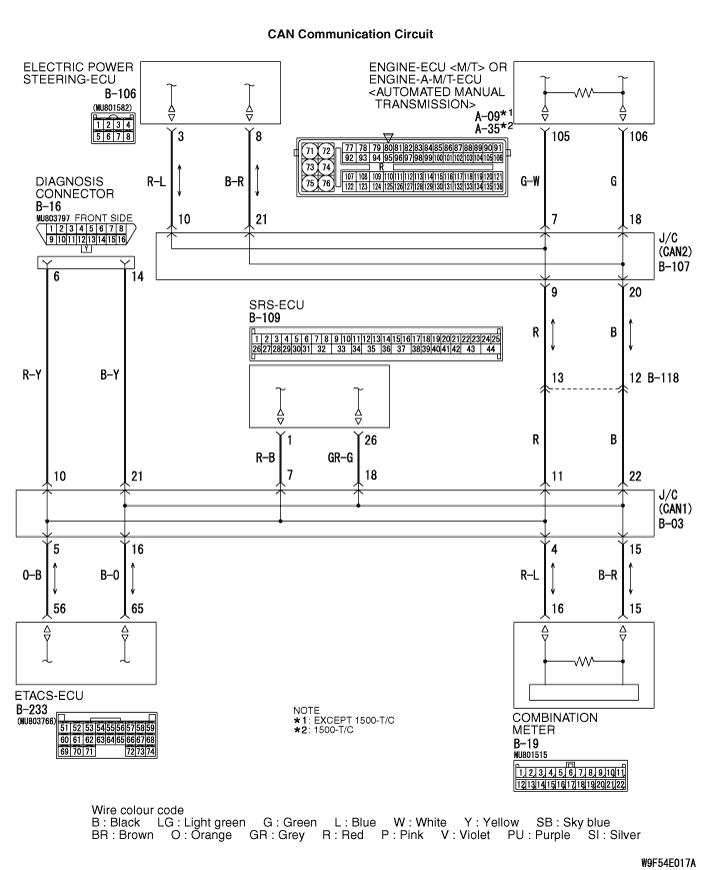

(3)Voltage between B-03 joint connector (CAN1) terminal No.15 and body earth

OK: 4.0 V or less

|

|

(4)Voltage between B-03 joint connector (CAN1) terminal No.16 and body earth

OK: 4.0 V or less

|

|

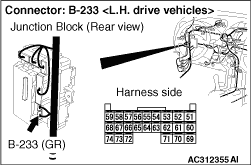

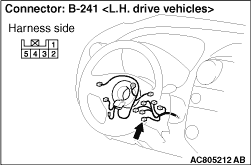

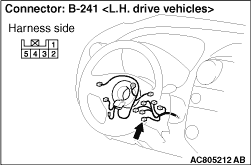

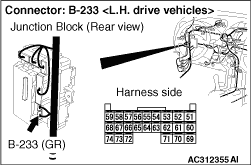

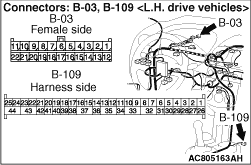

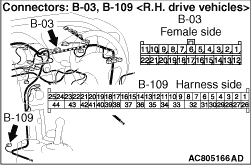

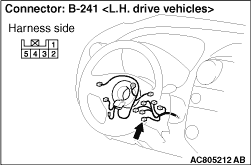

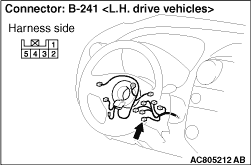

(5)Voltage between B-03 joint connector (CAN1) terminal No.17 and body earth <L.H. drive vehicles>

OK: 4.0 V or less

|

|

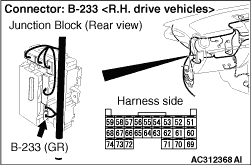

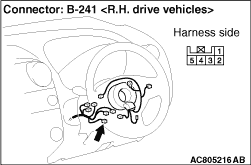

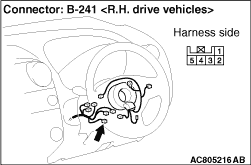

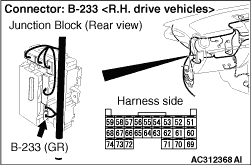

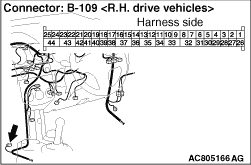

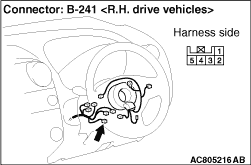

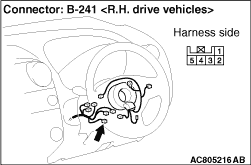

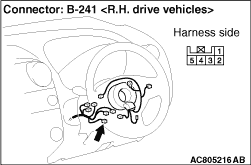

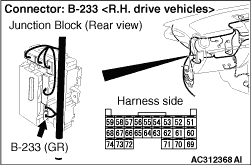

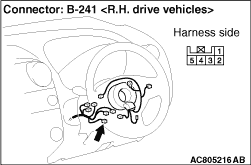

(6)Voltage between B-03 joint connector (CAN1) terminal No.14 and body earth <R.H. drive vehicles>

OK: 4.0 V or less

|

|

(7)Voltage between B-03 joint connector (CAN1) terminal No.18 and body earth

OK: 4.0 V or less

|

|

(8)Voltage between B-03 joint connector (CAN1) terminal No.20 and body earth

OK: 4.0 V or less

|

|

(9)Voltage between B-03 joint connector (CAN1) terminal No.21 and body earth

OK: 4.0 V or less

(10)Disconnect the negative battery terminal.

Q.

Are the check results normal?

YES <all of the measurement results show 4.0 V or less> : Go to Step 17. : Go to Step 17.

NO <The voltage between terminal No.15 and body earth is more than 4.0 V> : Go to Step 7. : Go to Step 7.

NO <The voltage between terminal No.16 and body earth is more than 4.0 V> : Go to Step 8. : Go to Step 8.

NO <The voltage between terminal No.17 and body earth is more than 4.0 V> : Go to Step 10. : Go to Step 10.

NO <The voltage between terminal No.14 and body earth is more than 4.0 V> : Go to Step 10. : Go to Step 10.

NO <The voltage between terminal No.18 and body earth is more than 4.0 V> : Go to Step 12. : Go to Step 12.

NO <The voltage between terminal No.20 and body earth is more than 4.0 V> : Go to Step 14. : Go to Step 14.

NO <The voltage between terminal No.21 and body earth is more than 4.0 V> : Go to Step 16. : Go to Step 16.

|

|

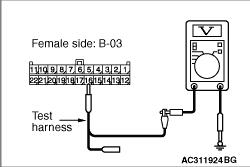

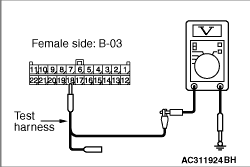

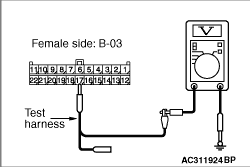

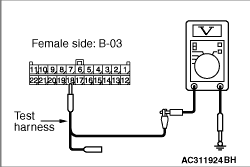

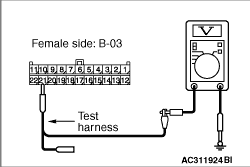

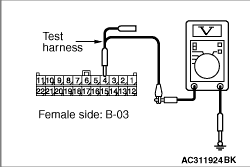

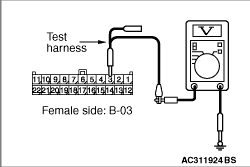

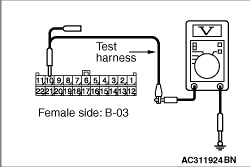

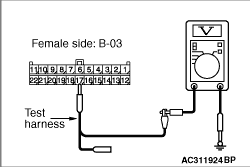

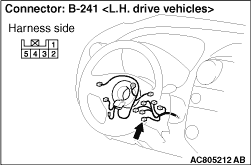

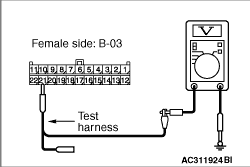

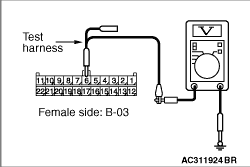

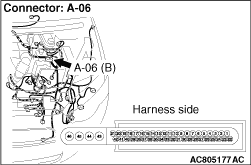

(1)Disconnect the joint connector (CAN1) and the combination meter connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.15 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector. <1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 9. Go to Step 9.

Repair the defective connector. Repair the defective connector.

|

|

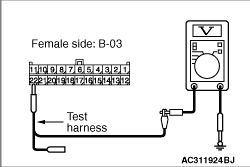

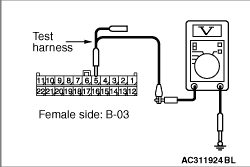

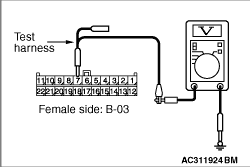

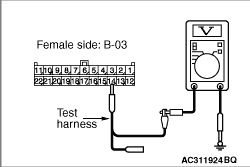

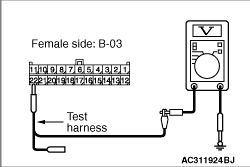

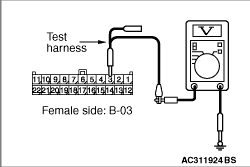

(1)Disconnect the joint connector (CAN1) and the ETACS-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.16 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 11. Go to Step 11.

Repair the defective connector. Repair the defective connector.

|

|

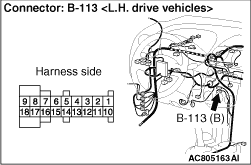

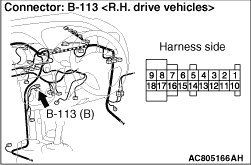

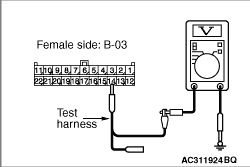

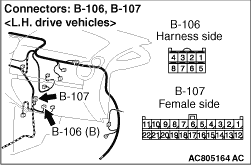

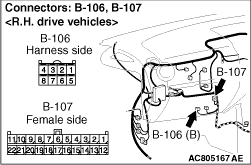

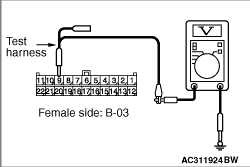

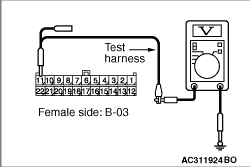

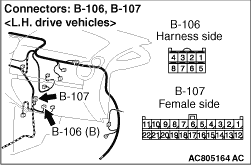

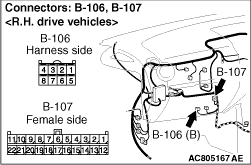

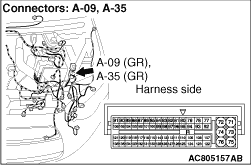

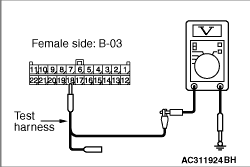

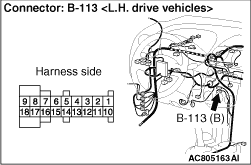

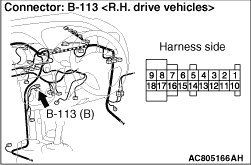

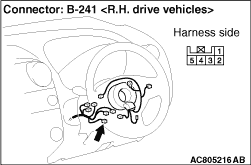

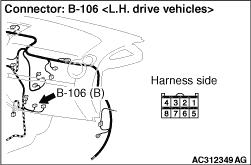

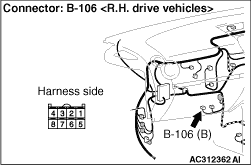

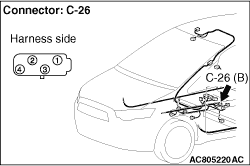

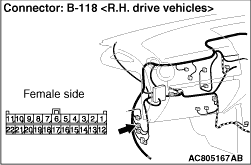

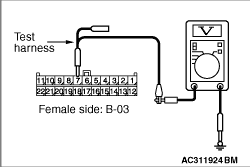

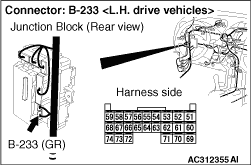

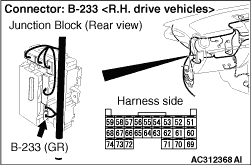

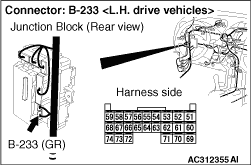

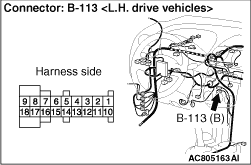

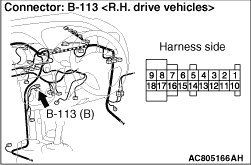

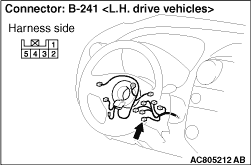

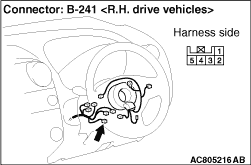

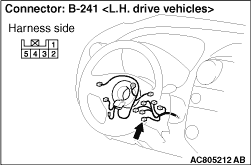

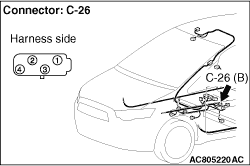

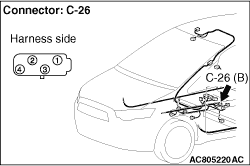

(1)Disconnect the joint connector (CAN1) and the A/C-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

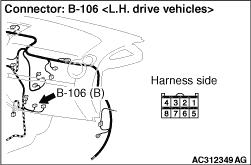

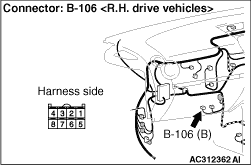

(3)Voltage between B-03 joint connector (CAN1) terminal No.17 and body earth <L.H. drive vehicles>

OK: Less than 1.0 V

|

|

(4)Voltage between B-03 joint connector (CAN1) terminal No.14 and body earth <R.H. drive vehicles>

OK: Less than 1.0 V

(5)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 13. Go to Step 13.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN1) and the SRS-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.18 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 15. Go to Step 15.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN1) and the steering wheel sensor connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.20 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

|

|

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.21 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

|

|

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.22 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

|

|

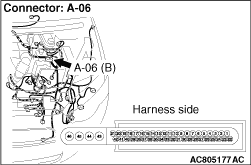

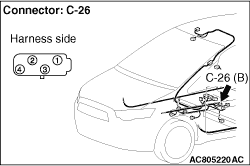

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

When checking the joint connector, ensure that its wiring harness side is not damaged.

Q.

Is the check result normal?

Go to Step 19. Go to Step 19.

Repair a defective connector or replace the joint connector (front wiring harness assembly). Repair a defective connector or replace the joint connector (front wiring harness assembly).

|

|

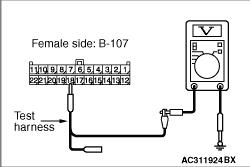

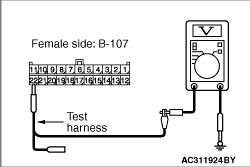

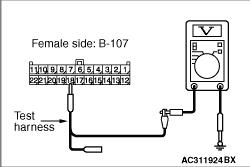

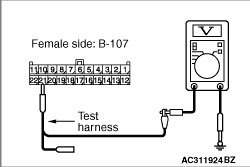

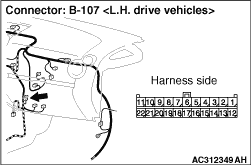

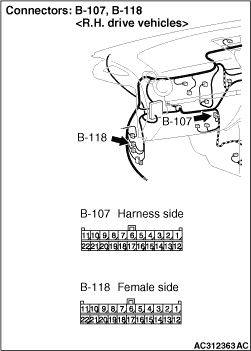

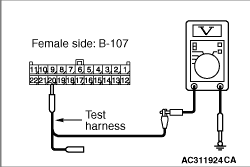

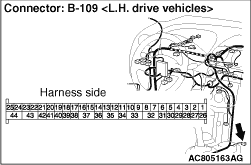

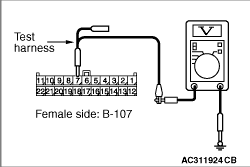

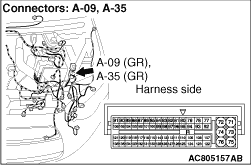

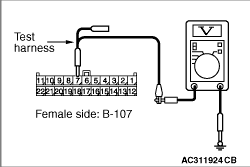

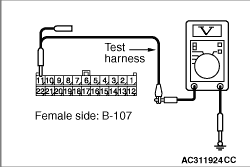

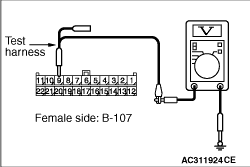

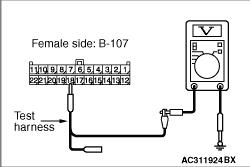

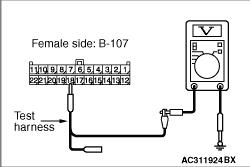

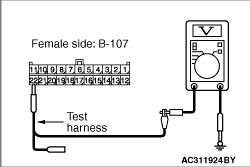

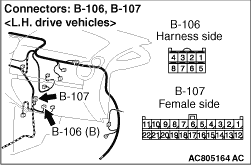

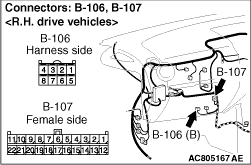

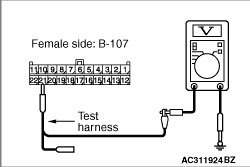

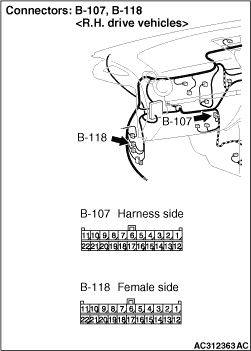

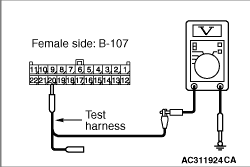

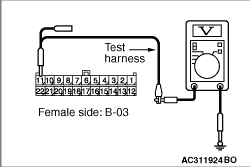

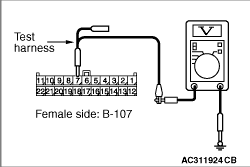

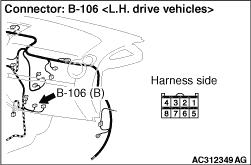

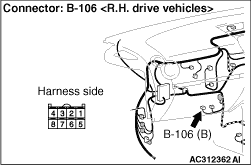

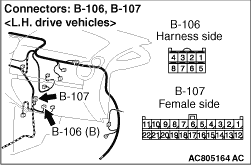

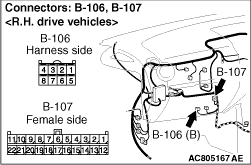

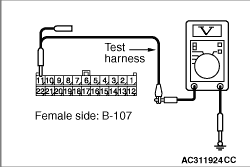

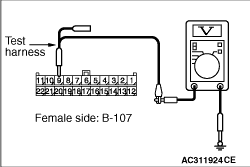

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.18 and body earth

OK: 4.0 V or less

|

|

(4)Voltage between B-107 joint connector (CAN2) terminal No.22 and body earth

OK: 4.0 V or less

|

|

(5)Voltage between B-107 joint connector (CAN2) terminal No.21 and body earth

OK: 4.0 V or less

|

|

(6)Voltage between B-107 joint connector (CAN2) terminal No.19 and body earth

OK: 4.0 V or less

(7)Disconnect the negative battery terminal.

Q.

Are the check results normal?

YES <all of the measurement results show 4.0 V or less> : Go to Step 27. : Go to Step 27.

NO <The voltage between terminal No.18 and body earth is more than 4.0 V> : Go to Step 20. : Go to Step 20.

NO <The voltage between terminal No.22 and body earth is more than 4.0 V> : Go to Step 21. : Go to Step 21.

NO <The voltage between terminal No.21 and body earth is more than 4.0 V> : Go to Step 23. : Go to Step 23.

NO <The voltage between terminal No.19 and body earth is more than 4.0 V> : Go to Step 25. : Go to Step 25.

|

|

(1)Disconnect the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector and the joint connector (CAN2), and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN1) terminal No.18 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector. <1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

|

|

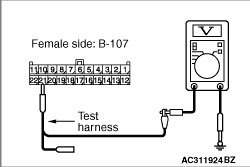

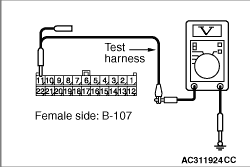

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 22. Go to Step 22.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the TCL/ASC-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.22 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

|

|

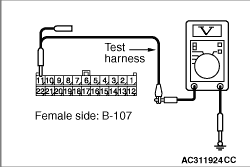

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 24. Go to Step 24.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the electric power steering-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.21 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

|

|

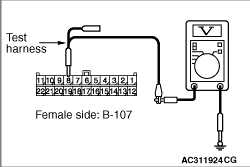

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 26. Go to Step 26.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the G and yaw rate sensor connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.19 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

|

|

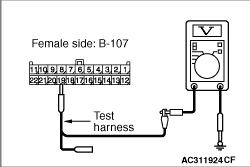

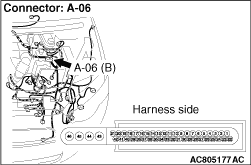

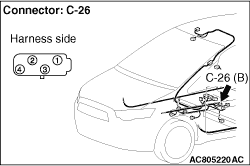

(1)Disconnect the joint connector (CAN2) and the intermediate connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.20 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.

|

|

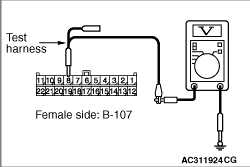

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 29. Go to Step 29.

Repair the defective connector. Repair the defective connector.

|

|

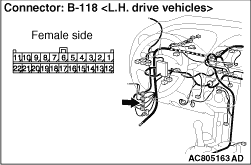

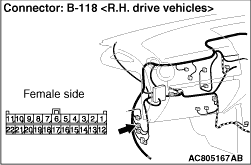

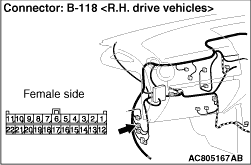

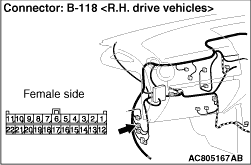

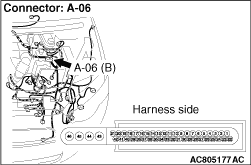

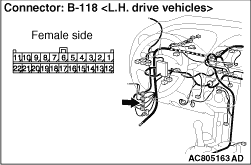

(1)Disconnect the connector, and measure at its female-side intermediate connector (at the front wiring harness side).

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-118 intermediate connector terminal No.13 and body earth

OK: 4.0 V or less

Q.

Is the check result normal?

<4.0 V or less> Go to Step 30. <4.0 V or less> Go to Step 30.

<more than 4.0 V> Go to Step 43. <more than 4.0 V> Go to Step 43.

|

|

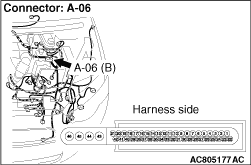

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

|

|

When checking the joint connector, ensure that its wiring harness side and its short pins are not damaged.

Q.

Is the check result normal?

Go to Step 31. Go to Step 31.

Repair a defective connector or replace the joint connector. Repair a defective connector or replace the joint connector.

|

|

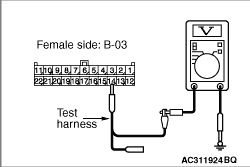

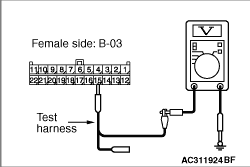

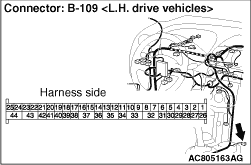

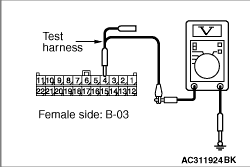

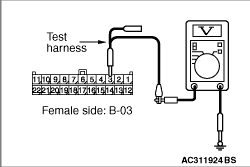

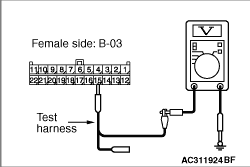

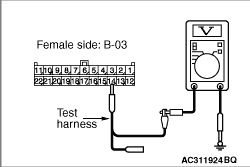

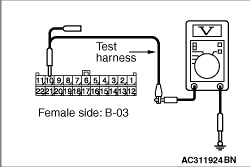

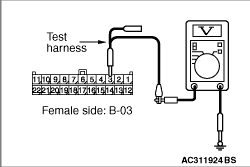

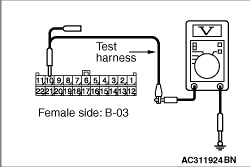

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

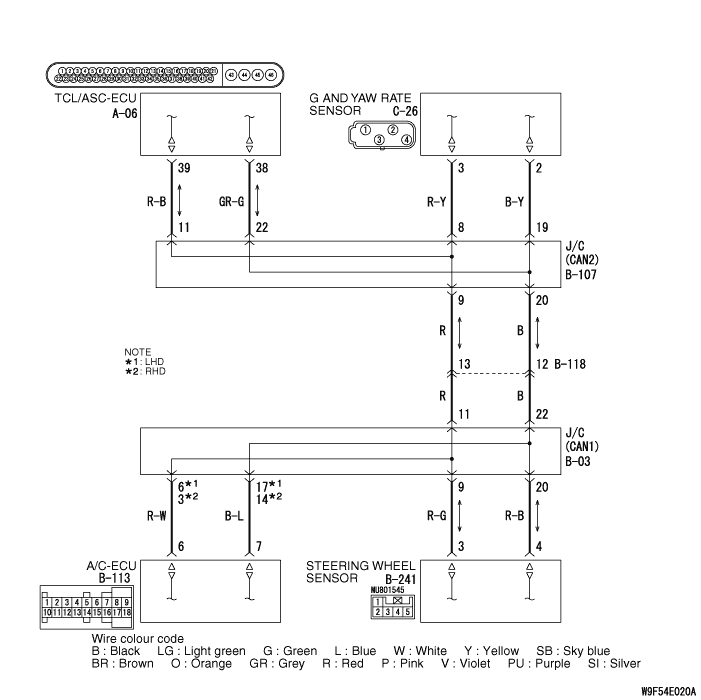

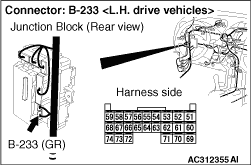

(3)Voltage between B-03 joint connector (CAN1) terminal No.4 and body earth

OK: 4.0 V or less

|

|

(4)Voltage between B-03 joint connector (CAN1) terminal No.5 and body earth

OK: 4.0 V or less

|

|

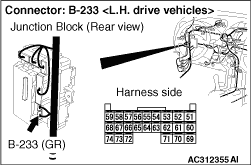

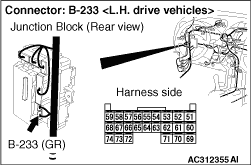

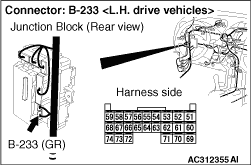

(5)Voltage between B-03 joint connector (CAN1) terminal No.6 and body earth <L.H. drive vehicles>

OK: 4.0 V or less

|

|

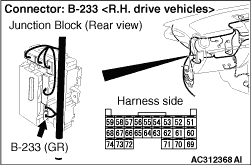

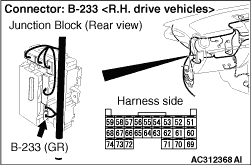

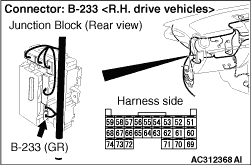

(6)Voltage between B-03 joint connector (CAN1) terminal No.3 and body earth <R.H. drive vehicles>

OK: 4.0 V or less

|

|

(7)Voltage between B-03 joint connector (CAN1) terminal No.7 and body earth

OK: 4.0 V or less

|

|

(8)Voltage between B-03 joint connector (CAN1) terminal No.9 and body earth

OK: 4.0 V or less

|

|

(9)Voltage between B-03 joint connector (CAN1) terminal No.10 and body earth

OK: 4.0 V or less

(10)Disconnect the negative battery terminal.

Q.

Are the check results normal?

YES <all of the measurement results show 4.0 V or less> : Go to Step 42. : Go to Step 42.

NO <The voltage between terminal No.4 and body earth is more than 4.0 V> : Go to Step 32. : Go to Step 32.

NO <The voltage between terminal No.5 and body earth is more than 4.0 V> : Go to Step 33. : Go to Step 33.

NO <The voltage between terminal No.6 and body earth is more than 4.0 V> : Go to Step 35. : Go to Step 35.

NO <The voltage between terminal No.3 and body earth is more than 4.0 V> : Go to Step 35. : Go to Step 35.

NO <The voltage between terminal No.7 and body earth is more than 4.0 V> : Go to Step 37. : Go to Step 37.

NO <The voltage between terminal No.9 and body earth is more than 4.0 V> : Go to Step 39. : Go to Step 39.

NO <The voltage between terminal No.10 and body earth is more than 4.0 V> : Go to Step 41. : Go to Step 41.

|

|

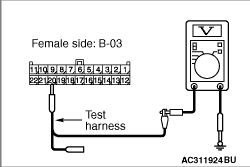

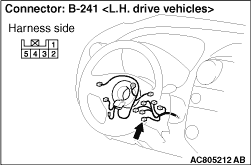

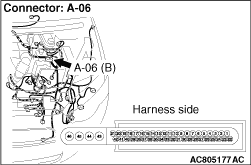

(1)Disconnect the joint connector (CAN1) and the combination meter connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.4 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector. <1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 34. Go to Step 34.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN1) and the ETACS-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.5 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 36. Go to Step 36.

Repair the defective connector. Repair the defective connector.

|

|

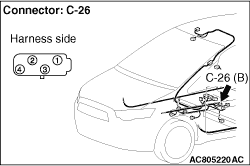

(1)Disconnect the joint connector (CAN1) and the A/C-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.6 and body earth <L.H. drive vehicles>

OK: Less than 1.0 V

|

|

(4)Voltage between B-03 joint connector (CAN1) terminal No.3 and body earth <R.H. drive vehicles>

OK: Less than 1.0 V

(5)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 38. Go to Step 38.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN1) and the SRS-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.7 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 40. Go to Step 40.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN1) and the steering wheel sensor connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.9 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

|

|

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.10 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

|

|

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-03 joint connector (CAN1) terminal No.11 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

|

|

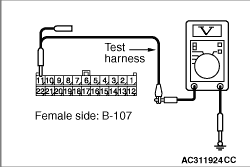

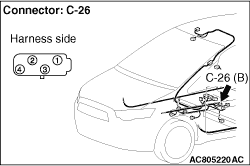

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

When checking the joint connector, ensure that its wiring harness side is not damaged.

Q.

Is the check result normal?

Go to Step 44. Go to Step 44.

Repair a defective connector or replace the joint connector (front wiring harness assembly). Repair a defective connector or replace the joint connector (front wiring harness assembly).

|

|

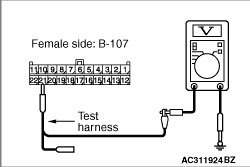

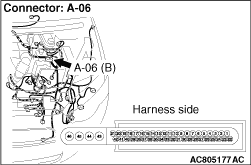

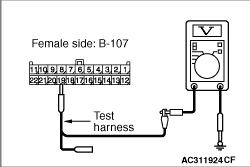

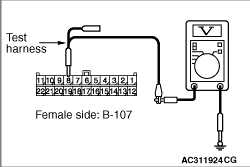

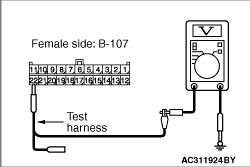

(1)Disconnect the connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.7 and body earth

OK: 4.0 V or less

|

|

(4)Voltage between B-107 joint connector (CAN2) terminal No.11 and body earth

OK: 4.0 V or less

|

|

(5)Voltage between B-107 joint connector (CAN2) terminal No.10 and body earth

OK: 4.0 V or less

|

|

(6)Voltage between B-107 joint connector (CAN2) terminal No.8 and body earth

OK: 4.0 V or less

(7)Disconnect the negative battery terminal.

Q.

Are the check results normal?

YES <all of the measurement results show 4.0 V or less> : Go to Step 52. : Go to Step 52.

NO <The voltage between terminal No.7 and body earth is more than 4.0 V> : Go to Step 45. : Go to Step 45.

NO <The voltage between terminal No.11 and body earth is more than 4.0 V> : Go to Step 46. : Go to Step 46.

NO <The voltage between terminal No.10 and body earth is more than 4.0 V> : Go to Step 48. : Go to Step 48.

NO <The voltage between terminal No.8 and body earth is more than 4.0 V> : Go to Step 50. : Go to Step 50.

|

|

(1)Disconnect the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector and the joint connector (CAN2), and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN1) terminal No.7 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector. <1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

|

|

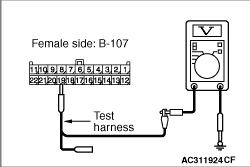

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 47. Go to Step 47.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the TCL/ASC-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.11 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 49. Go to Step 49.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the electric power steering-ECU connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.10 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

|

|

| caution |

The strand end of the twist wire should be within 10 cm from the connector. For details refer to  . .

|

Q.

Is the check result normal?

Go to Step 51. Go to Step 51.

Repair the defective connector. Repair the defective connector.

|

|

(1)Disconnect the joint connector (CAN2) and the G and yaw rate sensor connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.8 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

|

|

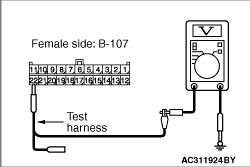

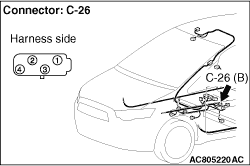

(1)Disconnect the joint connector (CAN2) and the intermediate connector, and measure at the wiring harness side.

(2)Connect the negative battery terminal, and turn the ignition switch to the ON position.

|

|

(3)Voltage between B-107 joint connector (CAN2) terminal No.9 and body earth

OK: Less than 1.0 V

(4)Disconnect the negative battery terminal.

| caution |

Strictly observe the specified wiring harness repair procedure. For details refer to  . .

|

Q.

Is the check result normal?

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction <less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector. <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.

|

.

. Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

Go to Step 4.

Go to Step 4. Repair the defective connector.

Repair the defective connector.

<4.0 V or less> Go to Step 5.

<4.0 V or less> Go to Step 5. <more than 4.0 V> Go to Step 18.

<more than 4.0 V> Go to Step 18.

Go to Step 9.

Go to Step 9. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

Go to Step 11.

Go to Step 11. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

Go to Step 13.

Go to Step 13. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

Go to Step 15.

Go to Step 15. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

Go to Step 19.

Go to Step 19. Repair a defective connector or replace the joint connector (front wiring harness assembly).

Repair a defective connector or replace the joint connector (front wiring harness assembly).

: Go to Step 27.

: Go to Step 27. : Go to Step 20.

: Go to Step 20. : Go to Step 21.

: Go to Step 21. : Go to Step 23.

: Go to Step 23. : Go to Step 25.

: Go to Step 25.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

<1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

Go to Step 22.

Go to Step 22. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

Go to Step 24.

Go to Step 24. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

Go to Step 26.

Go to Step 26. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.

Go to Step 29.

Go to Step 29. Repair the defective connector.

Repair the defective connector.

<4.0 V or less> Go to Step 30.

<4.0 V or less> Go to Step 30. <more than 4.0 V> Go to Step 43.

<more than 4.0 V> Go to Step 43.

Go to Step 31.

Go to Step 31. Repair a defective connector or replace the joint connector.

Repair a defective connector or replace the joint connector.

: Go to Step 42.

: Go to Step 42. : Go to Step 32.

: Go to Step 32. : Go to Step 33.

: Go to Step 33. : Go to Step 35.

: Go to Step 35. : Go to Step 35.

: Go to Step 35. : Go to Step 37.

: Go to Step 37. : Go to Step 39.

: Go to Step 39. : Go to Step 41.

: Go to Step 41.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

<1.0 V or more> Repair the wiring harness between joint connector (CAN1) and the combination meter connector.

Go to Step 34.

Go to Step 34. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the ETACS-ECU connector.

Go to Step 36.

Go to Step 36. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the A/C-ECU connector.

Go to Step 38.

Go to Step 38. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the SRS-ECU connector.

Go to Step 40.

Go to Step 40. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the steering wheel sensor connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the diagnosis connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN1) and the intermediate connector.

Go to Step 44.

Go to Step 44. Repair a defective connector or replace the joint connector (front wiring harness assembly).

Repair a defective connector or replace the joint connector (front wiring harness assembly).

: Go to Step 52.

: Go to Step 52. : Go to Step 45.

: Go to Step 45. : Go to Step 46.

: Go to Step 46. : Go to Step 48.

: Go to Step 48. : Go to Step 50.

: Go to Step 50.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

<1.0 V or more> Repair the wiring harness between the intermediate connector and the engine-ECU <M/T> or engine-A-M/T-ECU <Automated manual transmission> connector.

Go to Step 47.

Go to Step 47. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the TCL/ASC-ECU connector.

Go to Step 49.

Go to Step 49. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the electric power steering-ECU connector.

Go to Step 51.

Go to Step 51. Repair the defective connector.

Repair the defective connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the G and yaw rate sensor connector.

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction

<less than 1.0 V> It is determined that there is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ).

). <1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.

<1.0 V or more> Repair the wiring harness between the joint connector (CAN2) and the intermediate connector.