|

|

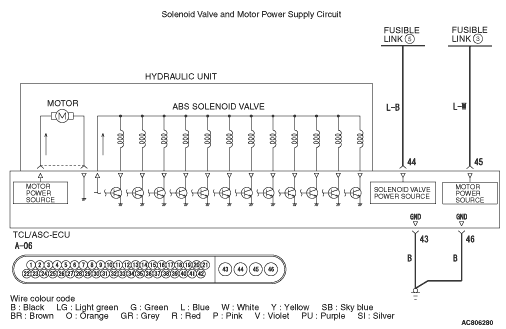

- The TCL/ASC-ECU contains the power supply circuit (terminal No.44)

for the solenoid valve. The solenoid valve is energised by the solenoid valve relay, which is

incorporated in the TCL/ASC-ECU.

- The valve relay, which is incorporated in the TCL/ASC-ECU, is always energising

the solenoid valve unless the initial check is in progress when the ignition switch is turned

on, or the recurrent system check is in progress.

|

|

|

These diagnosis codes will be set under the cases below:

|

|

|

Code No.C1276

- The ECU monitors the power supply voltage to the solenoid valve. If the voltage,

compared to the power supply voltage to the ECU, is lower than the predetermined value, the

ECU sets this diagnosis code as a failure in the valve relay circuit.

|

|

|

Code No.C1278

- When the solenoid valve is not energised even after the solenoid valve relay is

turned ON, the ECU determines that the solenoid valve relay stuck OFF and sets this diagnosis

code.

|

|

|

Code No.C1279

- When the solenoid valve is energised even after the solenoid valve relay is turned

OFF, the ECU determines that the solenoid valve relay stuck ON and sets this diagnosis code.

|

|

|

Current trouble

- Damaged wiring harness and connectors

- TCL/ASC-ECU malfunction

|

|

|

Past trouble

- Carry out diagnosis with particular emphasis on connector(s) or

wiring harness in the power supply circuit (terminal No.44) to the TCL/ASC-ECU solenoid valve

and earth circuit (terminal No.43 and No.46). For diagnosis procedures, refer to How to treat

past trouble (GROUP 00 - How to Cope with Intermittent Malfunction

). ).

|

|

|

Use M.U.T.-III to diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table  ).

On completion, go to Step 2. ).

On completion, go to Step 2.

|

|

|

|

|

|

Q.

Is the diagnosis code No.C1276, C1278 or C1279 set?

|

|

|

This diagnosis is complete. This diagnosis is complete.

|

|

|

|

|

|

Refer to GROUP 54A - Battery Test  . .

|

|

|

Q.

Is the battery in good condition?

|

|

|

Replace the battery. Then go to Step 11. Replace the battery. Then go to Step 11.

|

|

|

|

|

|

Refer to GROUP 16 - Charging System  . .

|

|

|

Q.

Is the charging system in good condition?

|

|

|

Repair or replace the charging system component(s). Then go to Step 11. Repair or replace the charging system component(s). Then go to Step 11.

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 6. Go to Step 6.

NO  : Repair the defective connector. Then go to Step 11. : Repair the defective connector. Then go to Step 11.

|

|

|

Visually check for open circuit in the fusible link No.5.

|

|

|

Q.

Is the check result normal?

|

|

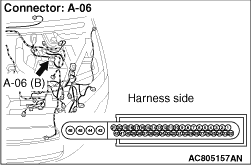

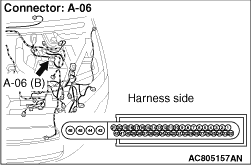

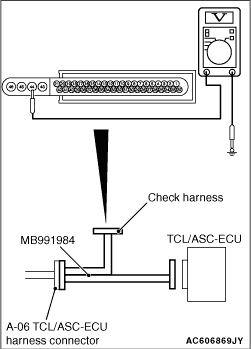

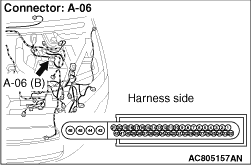

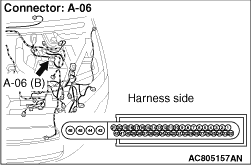

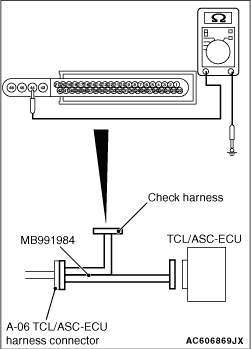

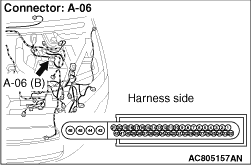

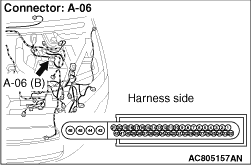

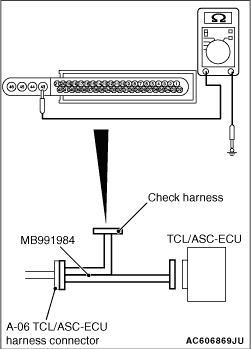

(1)Disconnect the TCL/ASC-ECU connector, connect special tool ABS check harness (MB991984)

to the harness-side connector, and then measure the resistance at the special tool connector side.

| note |

Do not connect the special tool ABS check harness (MB991984) to TCL/ASC-ECU.

|

|

|

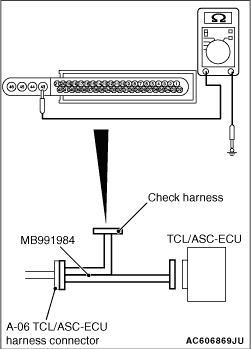

(2)Measure the resistance between the terminal No.44 and the body earth.

OK: No continuity

Q.

Is the check result normal?

Replace the fusible link No.5. Then go to Step 11. Replace the fusible link No.5. Then go to Step 11.

The short circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5, and then replace the fusible link No.5. Then go to Step 11. The short circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5, and then replace the fusible link No.5. Then go to Step 11.

|

|

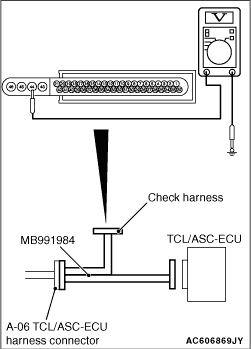

(1)Disconnect the TCL/ASC-ECU connector, connect special tool ABS check harness (MB991984)

to the harness-side connector, and then measure the voltage at the special tool connector side.

| note |

Do not connect the special tool ABS check harness (MB991984) to TCL/ASC-ECU.

|

|

|

(2)Measure the voltage between the terminal No.44 and the body earth.

OK: System voltage

Q.

Is the check result normal?

Go to Step 9. Go to Step 9.

The open circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5. Then go to Step 11. The open circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5. Then go to Step 11.

|

|

(1)Disconnect the TCL/ASC-ECU connector, connect special tool ABS check harness (MB991984)

to the harness-side connector, and then measure the resistance at the special tool connector side.

| note |

Do not connect the special tool ABS check harness (MB991984) to TCL/ASC-ECU.

|

|

|

(2)Measure the resistance between the terminal No.43 and the body earth, and between the

terminal No.46 and the body earth

OK: Continuity exists (2 Ω or less)

Q.

Is the check result normal?

Go to Step 10. Go to Step 10.

An open circuit may be present in the earth circuit. Repair the wiring harness

between the A-06 TCL/ASC-ECU connector terminal No.43 and the body earth, and between

the A-06 TCL/ASC-ECU connector terminal No.46 and the body earth. Then go to Step 11

. An open circuit may be present in the earth circuit. Repair the wiring harness

between the A-06 TCL/ASC-ECU connector terminal No.43 and the body earth, and between

the A-06 TCL/ASC-ECU connector terminal No.46 and the body earth. Then go to Step 11

.

|

|

|

Q.

Is the diagnosis code No.C1276, C1278 or C1279 set?

|

|

|

Replace the hydraulic unit (integrated with TCL/ASC-ECU) (Refer to Replace the hydraulic unit (integrated with TCL/ASC-ECU) (Refer to  ).

Then go to Step 11. ).

Then go to Step 11.

|

|

|

|

|

|

Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  ). ).

|

|

|

|

|

|

Q.

Is the diagnosis code No.C1276, C1278 or C1279 set?

|

|

|

This diagnosis is complete. This diagnosis is complete.

|

|

|

|

Go to Step 3.

Go to Step 3. Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table  ).

On completion, go to Step 2.

).

On completion, go to Step 2. Go to Step 3.

Go to Step 3. This diagnosis is complete.

This diagnosis is complete. .

. Go to Step 4.

Go to Step 4. Replace the battery. Then go to Step 11.

Replace the battery. Then go to Step 11. .

. Go to Step 5.

Go to Step 5. Repair or replace the charging system component(s). Then go to Step 11.

Repair or replace the charging system component(s). Then go to Step 11.

Go to Step 6.

Go to Step 6. : Repair the defective connector. Then go to Step 11.

: Repair the defective connector. Then go to Step 11. Go to Step 8.

Go to Step 8. Go to Step 7.

Go to Step 7.

Replace the fusible link No.5. Then go to Step 11.

Replace the fusible link No.5. Then go to Step 11. The short circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5, and then replace the fusible link No.5. Then go to Step 11.

The short circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5, and then replace the fusible link No.5. Then go to Step 11.

Go to Step 9.

Go to Step 9. The open circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5. Then go to Step 11.

The open circuit may be present in the power supply circuit. Repair the wiring

harness between the A-06 TCL/ASC-ECU connector terminal No.44 and the fusible link

No.5. Then go to Step 11.

Go to Step 10.

Go to Step 10. An open circuit may be present in the earth circuit. Repair the wiring harness

between the A-06 TCL/ASC-ECU connector terminal No.43 and the body earth, and between

the A-06 TCL/ASC-ECU connector terminal No.46 and the body earth. Then go to Step 11

.

An open circuit may be present in the earth circuit. Repair the wiring harness

between the A-06 TCL/ASC-ECU connector terminal No.43 and the body earth, and between

the A-06 TCL/ASC-ECU connector terminal No.46 and the body earth. Then go to Step 11

. Replace the hydraulic unit (integrated with TCL/ASC-ECU) (Refer to

Replace the hydraulic unit (integrated with TCL/ASC-ECU) (Refer to  ).

Then go to Step 11.

).

Then go to Step 11. Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction

Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  ).

). Return to Step 1.

Return to Step 1. This diagnosis is complete.

This diagnosis is complete.