|

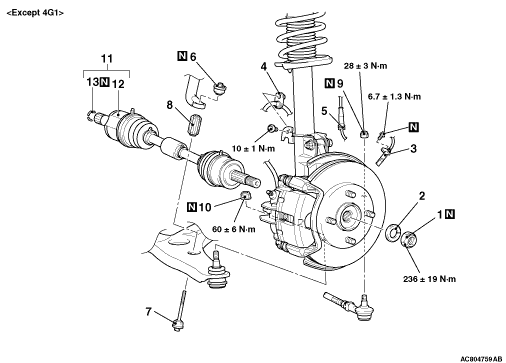

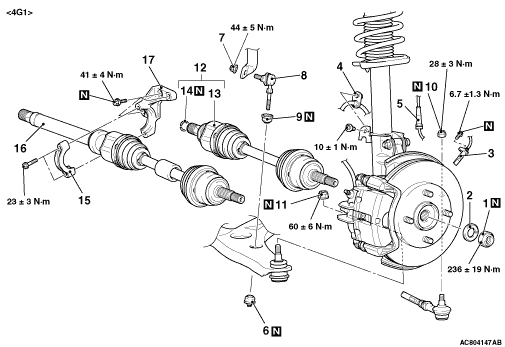

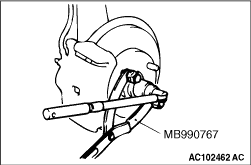

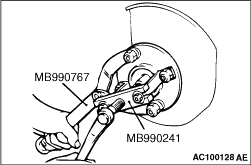

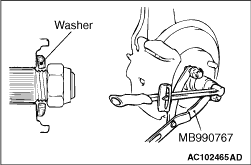

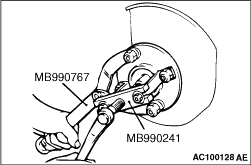

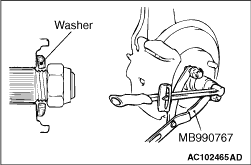

Use special tool front hub and flange yoke holder (MB990767) to fix the hub and remove

the driveshaft nut.

|

|

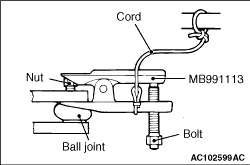

| caution |

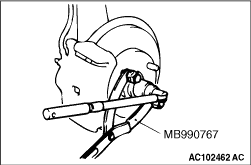

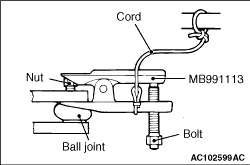

- Do not remove the nut from ball joint. Loosen it and use special

tool to avoid possible damage to ball joint threads.

- Hang special tool with cord to prevent it from falling.

Replace the self-locking nut with a regular nut, and then install special tool steering

linkage puller (MB991113) as shown in the figure.

|

|

|

1.

| caution |

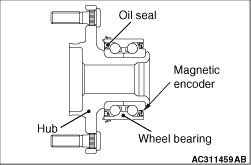

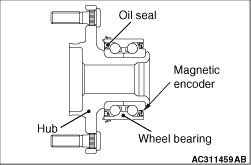

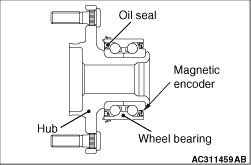

- The magnetic encoder collects any metallic particle easily, because it is magnetized.

Make sure that the magnetic encoder does not collect any metallic particle.

- When the driveshaft is removed, make sure that it does not contact with the magnetic

encoder and front wheel speed sensor to avoid damage.

|

Use the following special tools to push out the driveshaft or the driveshaft and inner

shaft assembly from the hub.

- Front hub and flange yoke holder (MB990767)

- Axle shaft puller (MB990241)

|

|

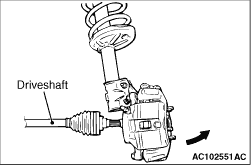

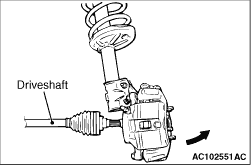

2.Remove the driveshaft from the hub by pulling the bottom of the brake disc towards you.

|

|

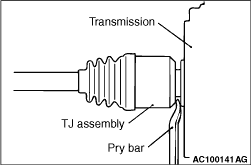

3.

| caution |

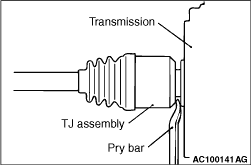

- Do not pull on the driveshaft; doing so

will damage the TJ; be sure to use the pry bar.

- When pulling the driveshaft out from the transmission, be careful that the spline

part of the driveshaft does not damage the oil seal.

|

Insert a pry bar between the transmission case and the driveshaft, and then pry and remove

the driveshaft from the transmission.

| note |

For vehicles with petrol engine 4G1 and diesel engine, it is not necessary to use a pry

bar in removal of the driveshaft (RH).

|

|

|

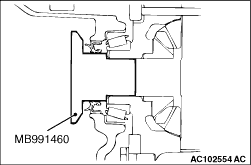

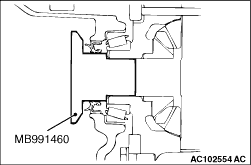

4.Use special tool plug (MB991460) to prevent the entry of foreign material into the transmission

case.

|

|

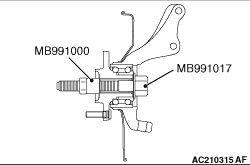

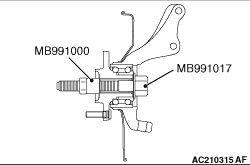

| caution |

Do not apply pressure to the wheel bearing by the vehicle weight to avoid possible damage

when the driveshaft is removed. If, however, vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel bearing by using the following special tools.

- Spacer (MB991000)

- Front hub remover and installer (MB991017)

|

|

|

| caution |

- The magnetic encoder collects any metallic particle easily, because it is magnetized.

Make sure that the magnetic encoder should not collect any metallic particle. Check that there

is not any trouble prior to reassembling it.

- When the driveshaft is installed, make sure that it does not contact with the magnetic

encoder and front wheel speed sensor to avoid damage.

- When installing the driveshaft, be careful that the driveshaft does not damage the

oil seal.

|

|

|

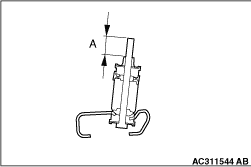

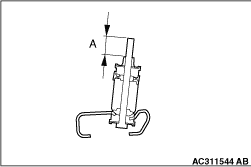

Install the stabilizer link bush (B) assembly, stabilizer link inner bush and stabilizer

link bush (A) as shown in the figure, and tighten the stabilizer link bush (A) so that the protruding

length of the stabilizer link bush (B) assembly meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

|

|

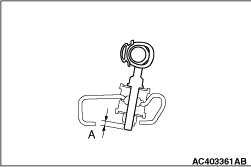

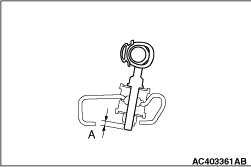

Install the stabilizer link bush (B), stabilizer link assembly and stabilizer link bush

(A) as shown in the figure, and tighten the stabilizer link bush (A) so that the protruding

length of the stabilizer link assembly meets its standard value (A).

Standard value (A): 5 ± 1.5 mm

|

|

1.Be sure to install the driveshaft washer in the specified direction.

2.

| caution |

Before securely tightening the driveshaft nuts, make

sure there is no load on the wheel bearings. Otherwise the wheel bearing will be damaged.

|

Using special tool front hub and flange yoke holder (MB990767), tighten the new driveshaft

nut to the specified torque.

Tightening torque: 236 ± 19 N·m

|

,

,  ).

). ,

,  ).

).