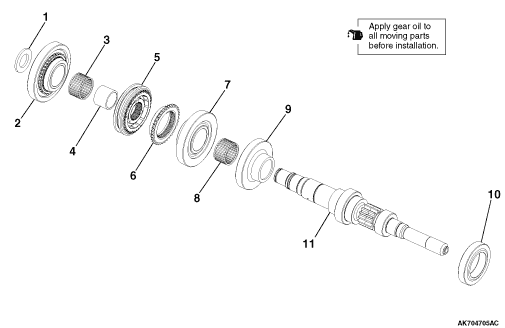

|

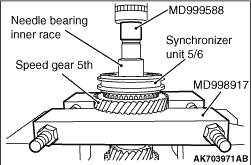

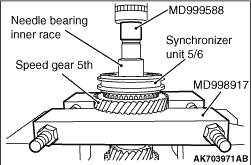

Using the special tools, support the speed gear 5th and remove the needle bearing inner

rase, synchronizer unit 5/6, dog body 5th and speed gear 5th.

- Bearing remover (MD998917)

- Valve guide installer (MD999588)

|

|

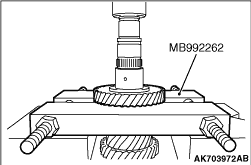

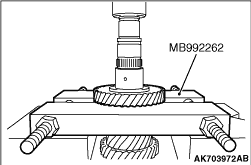

Using the special tool, Gear remover (MB992262), support the fixed gear 4th and remove

the fixed gear 4th.

|

|

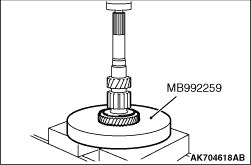

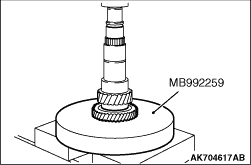

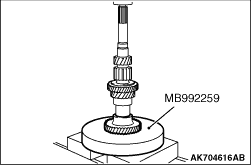

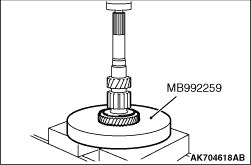

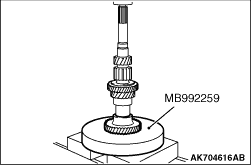

Using the special tool, Gear remover (MB992259), support the fixed gear 3rd and remove

the fixed gear 3rd.

|

|

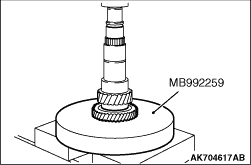

Using special tool, Gear remover (MB992259), install the fixed gear 3rd.

|

|

Using special tool, Gear remover (MB992259), install the fixed gear 4th.

|

|

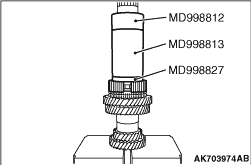

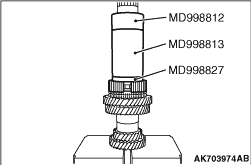

Using special tools, install the synchronizer unit 5/6.

- Installer cap (MD998812)

- Installer-100 (MD998813)

- Installer adapter (MD998827)

|

|

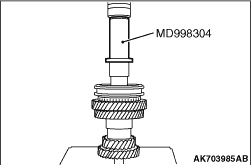

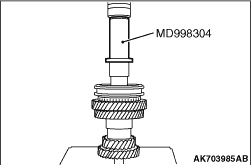

Using special tool, Crankshaft front oil seal installer (MD998304), install the needle

bearing inner rase.

|