Inspection Procedure 3: Shift actuator 1, 2 system malfunction

OPERATION

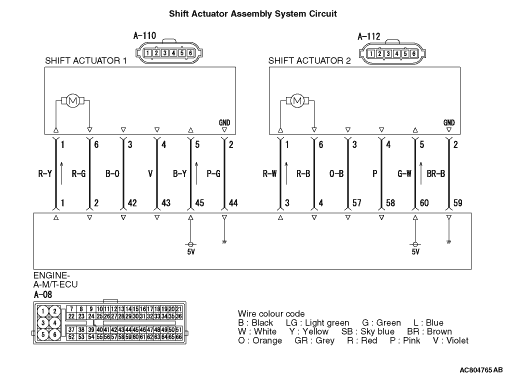

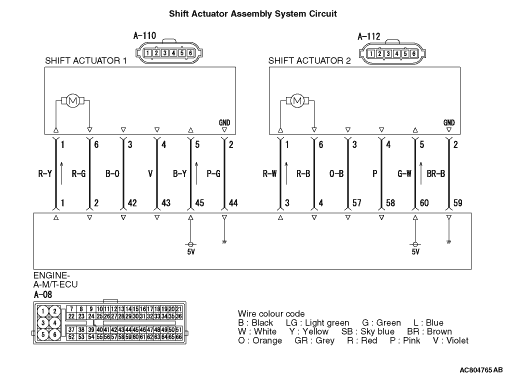

- Shift actuator 1 and 2 operate the motor inside according to signal from the engine-A-M/T-ECU. The motor is engaged with the gear of the drum that operates the shift fork. When the drum is turned, the shift fork operates and performs gear shift.

- Shift actuator 1 allows the transmission to shift to 1st, 3rd, 5th and 6th gear. Shift actuator 2 allows the transmission to shift to 2nd, 4th and reverse gear.

PROBABLE CAUSES

- Malfunction of shift actuator 1, 2

- Damaged harness wires and connectors

- Malfunction of the engine-A/T-ECU

|

|

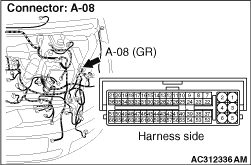

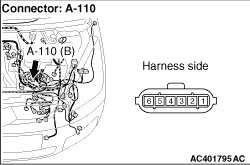

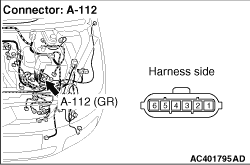

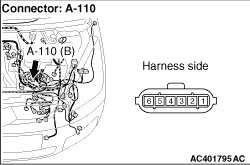

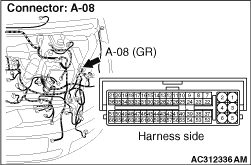

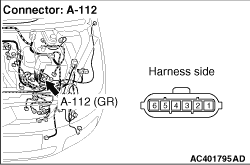

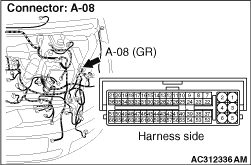

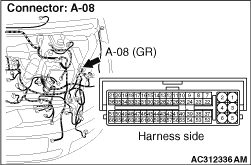

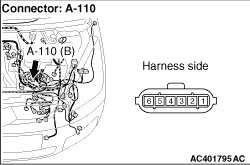

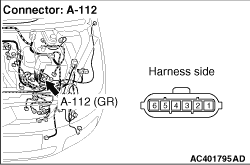

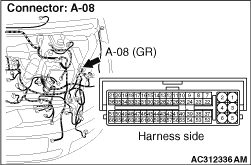

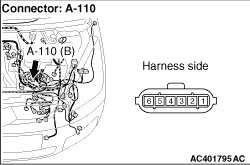

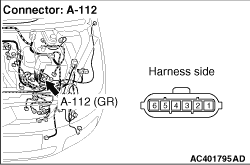

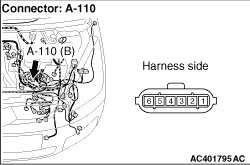

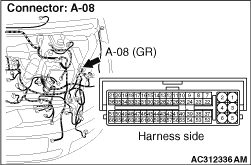

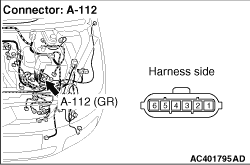

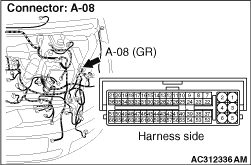

STEP 1. Connectors check: A-08 engine-A-M/T-ECU connector, A-110 shift actuator 1 connector, A-112 shift actuator 2 connector.

|

|

Check for the contact with terminals.

Q.

Is the check result normal?

Go to Step 2. Go to Step 2.

Repair the defective connector. Repair the defective connector.

|

|

|

STEP 2. Check the wiring harness between shift actuator 1 connector A-110 terminal No.1, 2, 3, 4, 5, 6 and engine-A-M/T-ECU connector A-08 terminal No.1, 44, 42, 43, 45, 2.

|

|

Check the wiring harness for short and open circuit.

Q.

Is the check result normal?

Go to Step 3. Go to Step 3.

Repair the wiring harness. Repair the wiring harness.

|

|

|

STEP 3. Check the wiring harness between shift actuator 2 connector A-112 terminal No.1, 2, 3, 4, 5, 6 and engine-A-M/T-ECU connector A-08 terminal No.3, 59, 57, 58, 60, 4.

|

|

Check the wiring harness for short and open circuit.

Q.

Is the check result normal?

Go to Step 4. Go to Step 4.

Repair the wiring harness. Repair the wiring harness.

|

|

|

STEP 4. Shift actuator 1, 2 replacement.

|

|

|

(1)Replace the shift actuator 1,2 (replace the shift actuator assembly).

|

|

|

(2)Test drive the vehicle.

|

|

|

(3)Check if a malfunction takes place again.

|

|

|

Q.

Does a malfunction take place again?

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

|

|

STEP 5. Engine-A-M/T-ECU replacement.

|

|

|

(1)Replace the engine-A-M/T-ECU. Then perform the variant coding and write the VIN data (Refer to GROUP 00, Precautions Before Service - How to Perform Variant Coding  ). ).

|

|

|

(2)Test drive the vehicle.

|

|

|

(3)Check if a malfunction takes place again.

|

|

|

Q.

Does a malfunction take place again?

|

|

|

Go to Step 1. Go to Step 1.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

Go to Step 2.

Go to Step 2. Repair the defective connector.

Repair the defective connector.

Go to Step 3.

Go to Step 3. Repair the wiring harness.

Repair the wiring harness.

Go to Step 4.

Go to Step 4. Repair the wiring harness.

Repair the wiring harness. Go to Step 5.

Go to Step 5. The inspection is complete.

The inspection is complete. ).

). Go to Step 1.

Go to Step 1. The inspection is complete.

The inspection is complete.