|

|

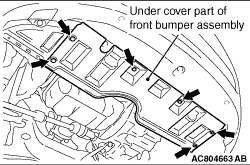

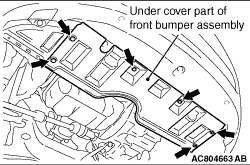

For adoption of the under cover integrated with the front bumper assembly, remove the

six front bumper clips, and lift the under cover part of front bumper assembly downward.

|

|

1.Remove the six front bumper clips shown in the figure.

|

|

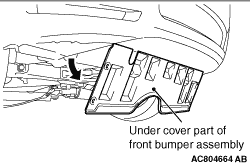

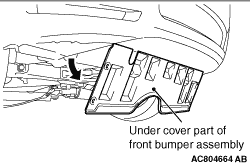

2.Lift the under cover part of front bumper assembly downward.

|

|

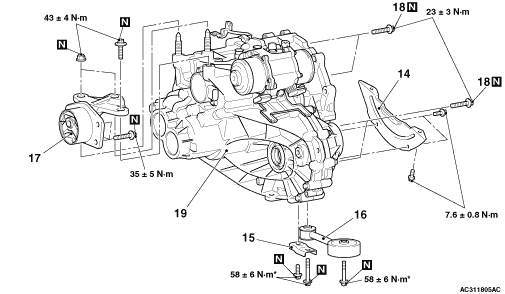

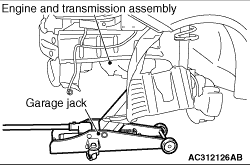

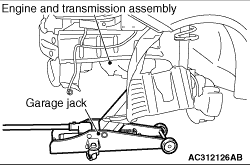

While supporting the engine and transmission assembly with a garage jack, remove the transmission

mounting insulator.

|

|

| caution |

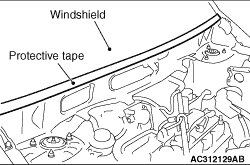

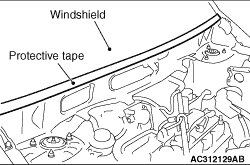

Wrap a protective tape to avoid damage to the windshield.

|

|

|

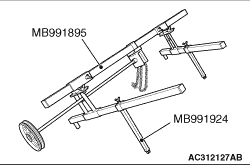

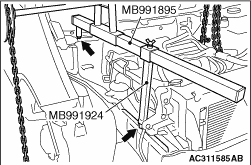

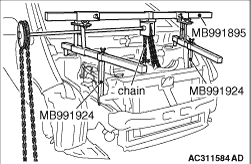

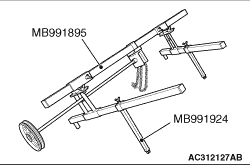

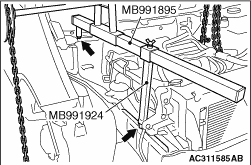

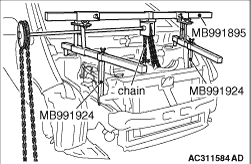

1.<Engine hanger (special tool MB991895) is used>

(1)

Remove the hook from the front side of engine hanger (special tool MB991895),

and install engine hanger attachment (special tool MB991924) instead.

(2)

Set the hook at the rear side of engine hanger (special tool MB991895) to the front strut

mounting nut

(3)

Set engine hanger attachment (special tool MB991924) to the front side member welded

part.

(4)

Attach the chain of engine hanger (special tool MB991895) to the engine assembly to support

the engine and transmission assembly.

|

|

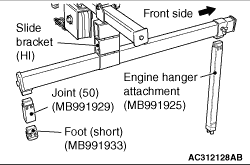

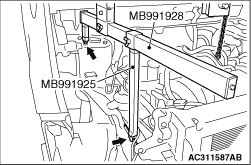

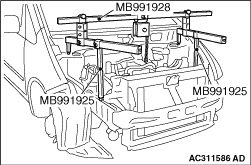

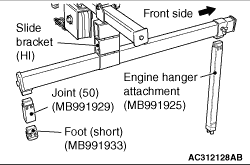

2.<Engine hanger (special tool MB991928) is used>

(1)

Assemble the engine hanger (special tool MB991928). Set following parts

to the base hanger.

- Slide bracket (HI)

- Engine hanger attachment (MB991925) <Front side>

- Foot (short) (MB991933) <Rear side>

- Joint (50) (MB991929) <Rear side>

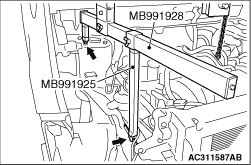

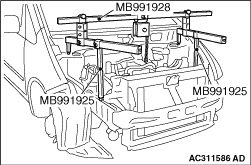

(2)

Set the foot (special tool MB991933) at the rear side of engine hanger (special tool MB991928)

to the front strut mounting nut.

(3)

Set engine hanger attachment (MB991925) to the front side member welded part.

(4)

Attach the chain of engine hanger (special tool MB991928) to the engine assembly to support

the engine and transmission assembly.

|

|

|

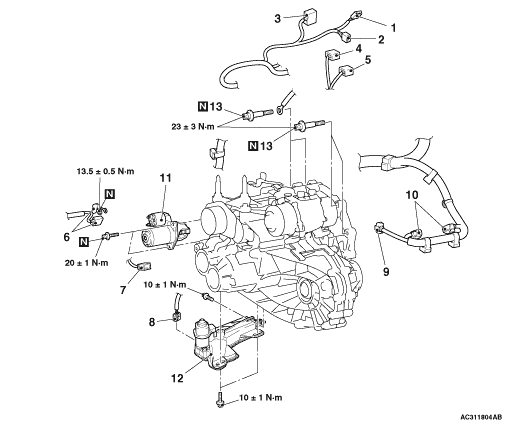

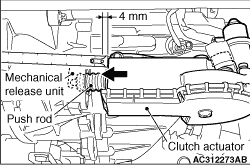

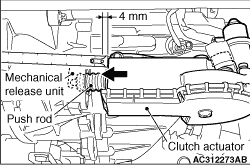

1.Tighten the clutch actuator mounting bolts temporarily at the point where the clutch

actuator push rod contacts with the mechanical release unit.

|

|

2.Gently depress the clutch actuator further 4 mm to the arrow direction from the point

where the push rod contacts with the mechanical release unit.

| note |

The depression amount should be measured by using a scale.

|

3.Tighten the mounting bolts to the specified torque.

Tightening torque: 10 ± 1 N·m

|

).

). ).

). <COLT> or

<COLT> or  <COLT-CZ3>).

<COLT-CZ3>). ).

). ).

). ).

). ).

). <COLT> or

<COLT> or  <COLT-CZ3>).

<COLT-CZ3>). ).

).