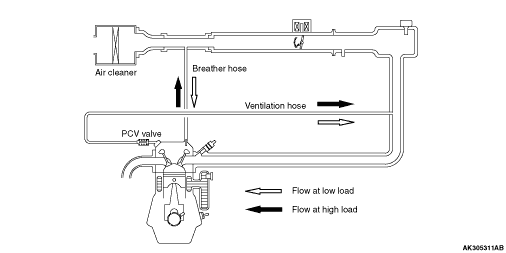

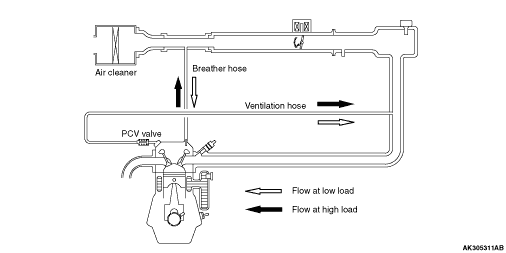

CRANKCASE VENTILATION

SYSTEM

The crankcase ventilation system prevents the blowby gas from being released into the atmosphere.

It consists of a ventilation hose that leads the blowby gas from the cylinder head cover to the

inlet manifold, a positive crankcase ventilation (PCV) valve that controls the blowby gas, and

a breather hose that leads air from the air intake hose to the cylinder head cover.

When the engine is running at low-load conditions, the inlet manifold vacuum causes the crankcase

blowby gas to pass from the cylinder head cover to the PCV valve and the ventilation hose and be

drawn into the inlet manifold, thus creating a vacuum in the crankcase. Along with this process, fresh

air passes from the air intake hose to the breather hose and the cylinder head cover, and enters

the crankcase.

When the engine is running under high-speed, high-load conditions (also, the throttle

valve is not opened fully), the blowby gas in the crankcase passes through the cylinder head

cover, PCV valve, and the ventilation hose, and enters the inlet manifold. At the same time,

the vacuum in the air intake hose draws the blowby gas from the breather hose into the inlet

manifold, via the throttle valve.

PCV VALVE

The PCV valve controls the intake amount of the blowby gas in accordance with the inlet

manifold vacuum. Therefore, under low-load conditions, this valve restricts the blowby intake

amount in order to ensure the stability of the engine. The amount of the intake blowby gas also

increases as the load becomes high. However, the amount of the intake blowby gas decreases because

the inlet manifold pressure becomes to be closer to the atmospheric pressure as the throttle

valve opens more fully.