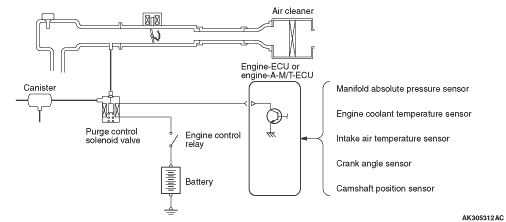

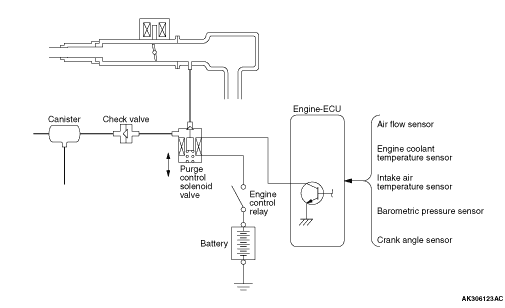

The engine-ECU or engine-A-M/T-ECU controls the actuation of the purge control solenoid valve in accordance with the signals provided by the crankshaft position sensor and the manifold absolute pressure (MAP) sensor <134, 135> or air flow sensor <4G1>. The fuel vapour intake amount is proportionate to the ON duty cycle ratio.