|

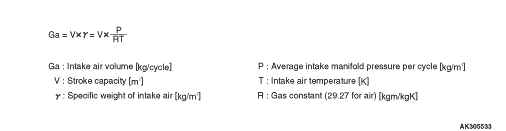

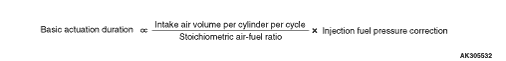

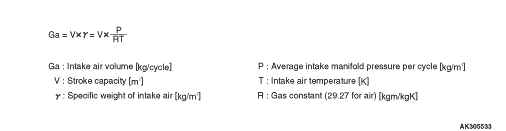

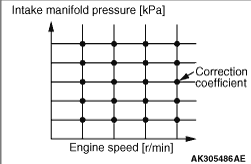

However, the volume of air that is actually drawn into the engine will be influenced by

factors such as the valve train or the intake air pulsations. Therefore, the actual air volume

will be less than the calculated air volume at a given rate, in accordance with the engine speed

and the intake manifold pressure.

For this reason, the calculated intake air volume is corrected by a map value, which has

been predetermined for the respective engine speed and intake manifold pressure, so that it

will be equal to the actual intake air volume.

Dividing the intake air volume after the correction into four parts will yield the actual

intake air volume per cylinder per cycle.

|

|

|

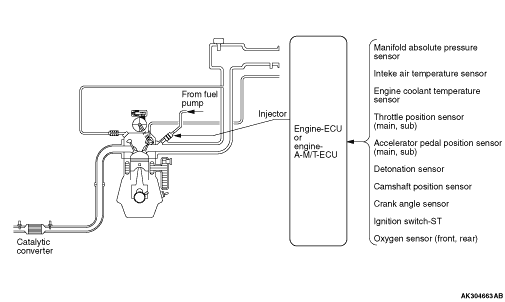

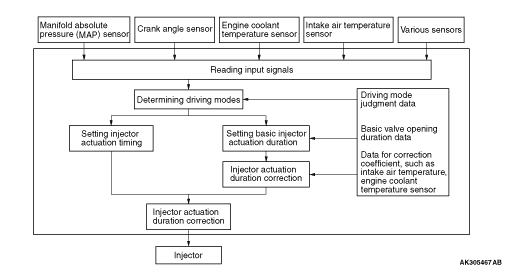

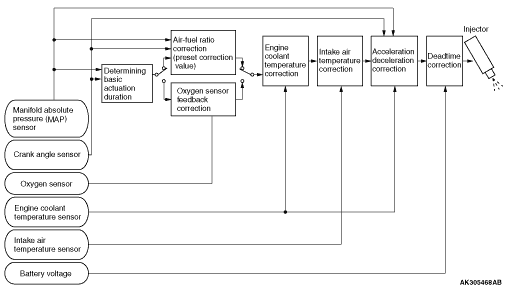

An oxygen sensor feedback correction or an air-fuel ratio correction is made after the

basic injector actuation duration has been determined.

|

|

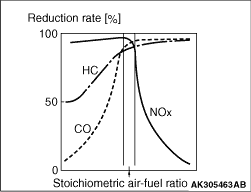

- Oxygen Sensor Feedback Correction

During normal driving, the injector actuation duration is corrected in accordance with

the oxygen sensor signals in order to attain the stoichiometric air-fuel ratio in which the reduction

rate of the three-way catalyst is at the optimum level.

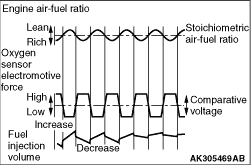

Operation

If the actual air-fuel ratio is richer than the stoichiometric air-fuel ratio, the oxygen

concentration in the exhaust gases is low. Therefore, the oxygen sensor will input a high electromotive

force (rich signal) into the engine-ECU or engine-A-M/T-ECU.

When the engine-ECU or engine-A-M/T-ECU receives a rich signal, it decreases the feedback

correction coefficient in order to decrease the fuel injection volume.

Conversely, if the actual air-fuel ratio is leaner than the stoichiometric air-fuel ratio,

the oxygen concentration in the exhaust gases is high. Therefore, the oxygen sensor will input

a low electromotive force (lean signal) into the engine-ECU or engine-A-M/T-ECU.

When the engine-ECU or engine-A-M/T-ECU receives a lean signal, it increases the feedback

correction coefficient in order to increase the fuel injection volume.

The system continuously effects feedback control in this manner in order to attain the

correct stoichiometric air-fuel ratio.

To ensure the proper driveability, this control will not be effected under the conditions

given below (instead, it will make an air-fuel ratio correction).

- Starting the engine

- Sudden acceleration or deceleration

- High-speed operation

- Cold engine

- High-load operation

- Oxygen sensor inactive

- Oxygen Sensor Deterioration Correction

The performance of the oxygen sensor (front), which is installed upstream of the catalytic

converter, deteriorates gradually with the prolonged use of the vehicle or the increase in its

mileage.

However, the performance of the oxygen sensor (rear), which is installed downstream of

the catalytic converter, hardly deteriorates because the catalytic converter cleans the exhaust

gases.

The engine-ECU or engine-A-M/T-ECU effects feedback control by using the signals that

are output by the oxygen sensor (front). Also, it uses the signals that are output by the oxygen

sensor (rear) in order to correct the signals that are output by the oxygen sensor (front).

Therefore, the air-fuel ratio can be controlled accurately even if the performance of the oxygen

sensor (front) deteriorates.

- Air-Fuel Ratio Correction

Except when oxygen sensor feedback control is being effected, the intake air volume is

corrected through a map value, which has been predetermined for the respective engine speed

and intake manifold pressure.

Then, the corrections indicated below are made in order to determine an optimal fuel injection

volume.

- Atmospheric Pressure Correction

As the intake air density changes with the changes in the atmospheric pressure, the deviation

in the air-fuel ratio, which is caused by this difference in density, must be corrected. The

atmospheric pressure is estimated based on the voltage that is output by the manifold absolute

pressure (MAP) sensor with the ignition switch turned ON (engine stopped) and a wide-open-throttle.

- Engine Coolant Temperature Correction

To ensure the proper drivability when the engine coolant temperature is low, a correction

is made to increase the fuel injection volume.

- Intake Air Temperature Correction

As the intake air density changes with the changes in the intake air temperature, a correction

is made in the deviation in the air-fuel ratio, which is caused by this difference in temperature.

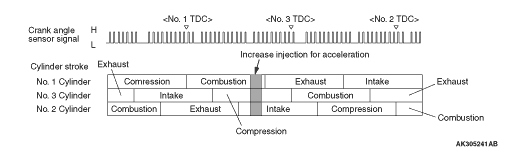

- Acceleration and Deceleration Correction

A correction is made in accordance with the changes in the intake air volume in order

to ensure the proper driveability during sudden acceleration or deceleration.

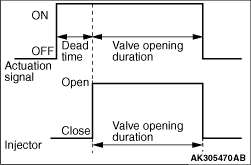

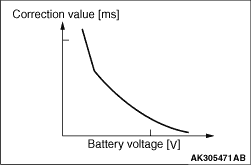

- Dead Time Correction

The injector valve opens in accordance with the actuation signals provided by the engine-ECU

or engine-A-M/T-ECU. This action is delayed as the battery voltage decreases, making the injector

spray a lower volume of fuel than the target fuel injection volume. For this reason, a correction

is made in accordance with the battery voltage.

|

|

|

When the vehicle is decelerating, such as when driving downhill, the control limits the

delivery of fuel in order to protect the catalyst from overheating and improve fuel economy.

|

|

|

When the engine operates above the predetermined speed of 6,800 r/min, this control cuts

off fuel to protect the engine by preventing it from overrunning.

|