|

|

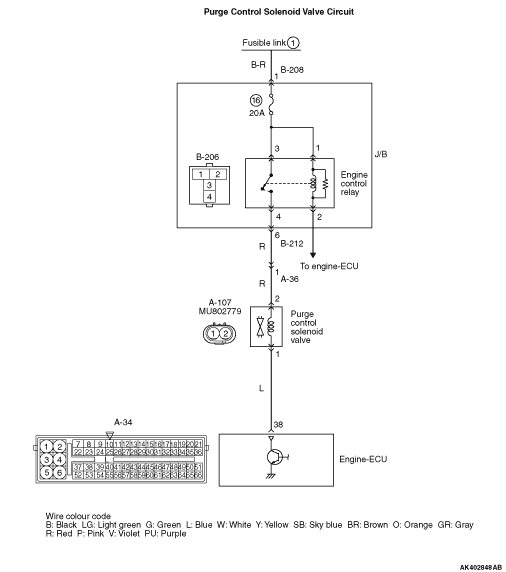

- Item No. 6: Purge control solenoid valve

|

|

|

OK: Operating sound can be heard and the valve vibrates

|

|

|

Q.

Is the check result normal?

|

|

|

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions  ). ).

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 3 . Go to Step 3 .

Repair or replace the connector. Repair or replace the connector.

|

|

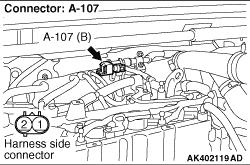

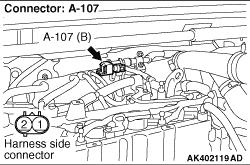

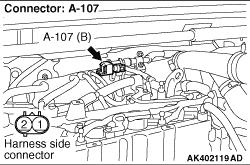

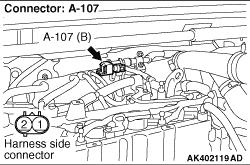

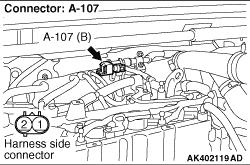

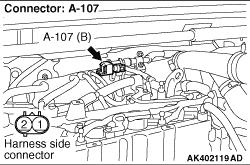

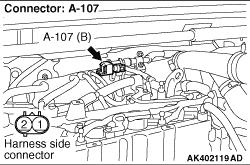

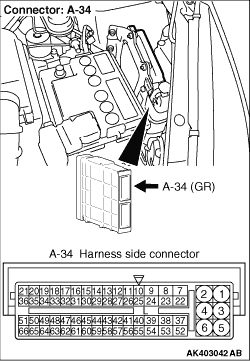

- Disconnect connector, and measure at solenoid valve side.

- Resistance between terminal No. 1 and No. 2.

OK: 30 - 34 Ω (at 20°C)

Q.

Is the check result normal?

Go to Step 4 . Go to Step 4 .

Replace the purge control solenoid valve. Replace the purge control solenoid valve.

|

|

- Disconnect connector, and measure at harness side.

- Ignition switch: ON

- Voltage between terminal No. 2 and earth.

OK: System voltage

Q.

Is the check result normal?

Go to Step 6 . Go to Step 6 .

Go to Step 5 . Go to Step 5 .

|

|

Q.

Is the check result normal?

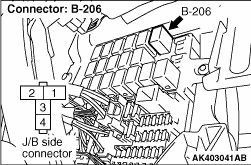

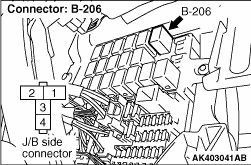

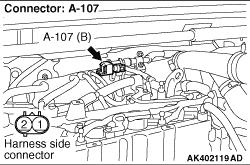

Check intermediate connector A-36 and B-212,

and repair if necessary. If intermediate connector is normal, check and repair harness between

A-107 (terminal No. 2) purge control solenoid valve connector and B-206 (terminal No. 4) engine control

relay connector.

- Check power supply line for open/short circuit.

Repair or replace the connector. Repair or replace the connector.

|

|

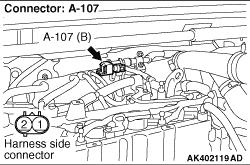

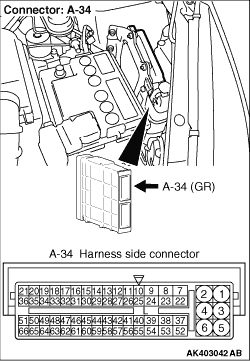

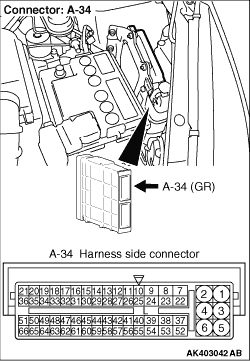

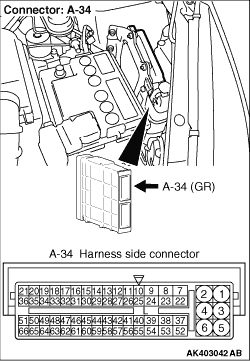

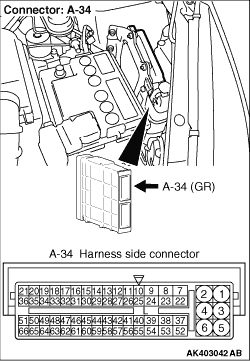

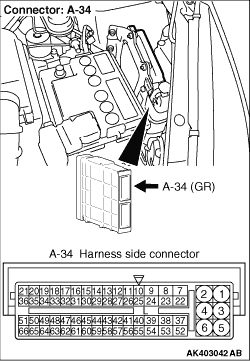

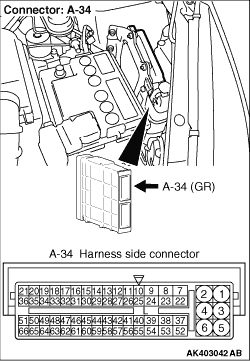

- Disconnect connector, and measure at harness side.

- Ignition switch: ON

- Voltage between terminal No. 38 and earth.

OK: System voltage

Q.

Is the check result normal?

Go to Step 8 . Go to Step 8 .

Go to Step 7 . Go to Step 7 .

|

|

Q.

Is the check result normal?

Check and repair harness between A-107 (terminal No.

1) purge control solenoid valve connector and A-34 (terminal No. 38) engine-ECU connector.

- Check earthing line for open/short circuit.

Repair or replace the connector. Repair or replace the connector.

|

|

Q.

Is the check result normal?

Go to Step 9 . Go to Step 9 .

Repair or replace the connector. Repair or replace the connector.

|

|

- Check earthing line for damage.

Q.

Is the check result normal?

Go to Step 10 . Go to Step 10 .

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

| note |

Before checking harness, check intermediate connector A-36 and B-212, and repair if necessary.

|

- Check power line for damage.

Q.

Is the check result normal?

Go to Step 11 . Go to Step 11 .

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

- Item No. 6: purge control solenoid valve

|

|

|

OK: Operating sound can be heard and the valve vibrates

|

|

|

Q.

Is the check result normal?

|

|

|

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions  ). ).

|

|

|

|

|

|

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions

Before Service - How to Perform Variant Coding Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions

Before Service - How to Perform Variant Coding  ). ).

|

|

|

|

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions  ).

).

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions  ).

). Go to Step 2 .

Go to Step 2 .

Go to Step 3 .

Go to Step 3 . Repair or replace the connector.

Repair or replace the connector.

Go to Step 6 .

Go to Step 6 . Go to Step 5 .

Go to Step 5 .

Go to Step 8 .

Go to Step 8 . Go to Step 7 .

Go to Step 7 .

Go to Step 9 .

Go to Step 9 . Repair or replace the connector.

Repair or replace the connector.

Go to Step 10 .

Go to Step 10 . Repair the damaged harness wire.

Repair the damaged harness wire. Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points - How to Cope with Intermittent Malfunctions  ).

). Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions

Before Service - How to Perform Variant Coding

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions

Before Service - How to Perform Variant Coding  ).

).