|

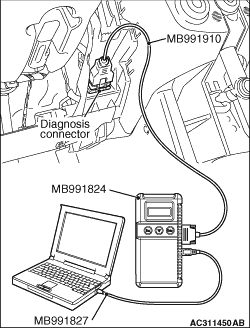

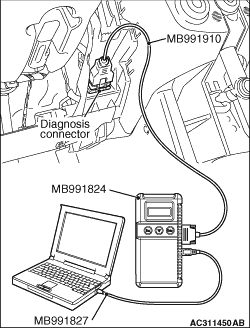

- Connect the M.U.T.-III to the diagnosis connector.

- Ignition switch: ON

- When the V.C.I. is energised, the V.C.I. indicator lamp should be illuminate in

a green colour.

OK: The V.C.I. indicator lamp illuminates in a green colour.

Q.

Is the check result normal?

Go to Step 6 . Go to Step 6 .

Go to Step 2 . Go to Step 2 .

|

|

|

- Measure battery voltage during cranking.

|

|

|

Q.

Is the check result normal?

|

|

|

Check battery (Refer to GROUP 54A -

Battery -

On-vehicle Service -

Battery

Test Check battery (Refer to GROUP 54A -

Battery -

On-vehicle Service -

Battery

Test  ). ).

|

|

|

|

|

Q.

Is the check result normal?

Go to Step 4 . Go to Step 4 .

Repair or replace the connector. Repair or replace the connector.

|

|

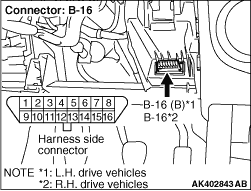

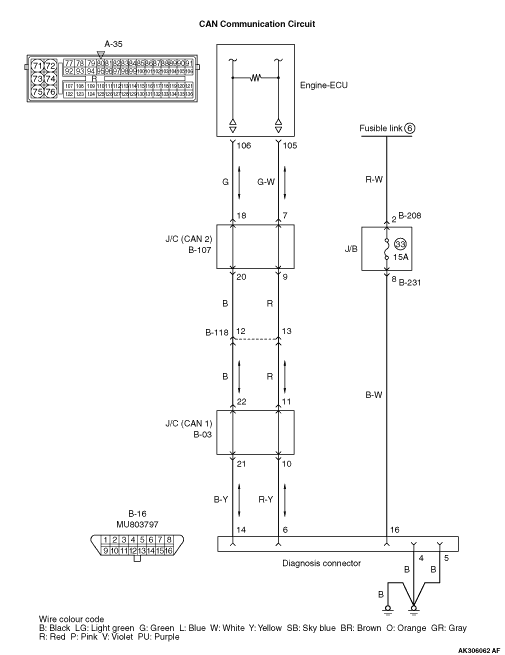

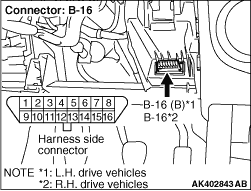

- Voltage between terminal No. 16 and earth.

OK: System voltage

Q.

Is the check result normal?

Go to Step 5 . Go to Step 5 .

Check intermediate connector B-208 and B-231,

and repair if necessary. If intermediate connector is normal, check and repair harness between

B-16 (terminal No. 16) diagnosis connector and battery.

- Check power supply line for open/short circuit.

|

|

- Resistance between terminal No. 4 and earth, also between terminal No. 5

and earth.

OK: Continuity (2 Ω or less)

Q.

Is the check result normal?

Refer to M.U.T.-III User’

s Manual -

Troubleshooting Procedures. Refer to M.U.T.-III User’

s Manual -

Troubleshooting Procedures.

Check and repair harness between diagnosis connector

and body earth.

- Check and repair harness between B-16 (terminal No.

4) diagnosis connector and body earth.

- Check and repair harness between B-16 (terminal No. 5) diagnosis connector and body earth.

- Check earthing line for open circuit and damage

|

|

|

- Using M.U.T.-III, perform CAN bus line diagnosis.

|

|

|

Q.

Is the check result normal?

|

|

|

Check engine-ECU power supply, engine control relay and ignition switch IG1 system

(Refer to Inspection Procedure 21 Check engine-ECU power supply, engine control relay and ignition switch IG1 system

(Refer to Inspection Procedure 21  ). ).

|

|

|

|

|

|

Correct CAN bus line (Refer to GROUP 54C -

Troubleshooting -

Can

Bus Diagnosis Table  ). ).

|

|

|

|

Go to Step 6 .

Go to Step 6 . Go to Step 2 .

Go to Step 2 .

Go to Step 3 .

Go to Step 3 . Check battery (Refer to GROUP 54A -

Battery -

On-vehicle Service -

Battery

Test

Check battery (Refer to GROUP 54A -

Battery -

On-vehicle Service -

Battery

Test  ).

).

Go to Step 4 .

Go to Step 4 . Repair or replace the connector.

Repair or replace the connector. Check engine-ECU power supply, engine control relay and ignition switch IG1 system

(Refer to Inspection Procedure 21

Check engine-ECU power supply, engine control relay and ignition switch IG1 system

(Refer to Inspection Procedure 21  ).

).