|

|

Inspection chart for diagnosis code (Refer to Inspection chart for diagnosis code (Refer to  ). ).

|

|

|

|

|

|

- Refer to Data List Reference Table

. .

- Item No. 6: Intake air temperature sensor

- Item No. 8: Engine coolant temperature sensor

- Item No. 11: Accelerator pedal position sensor (main)

- Item No. 12: Accelerator pedal position sensor (sub)

- Item No. 13: Throttle position sensor (main)

- Item No. 14: Throttle position sensor (sub)

- Item No. 80: Air flow sensor

|

|

|

Q.

Are the check results normal?

|

|

|

Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code  ). ).

|

|

|

|

|

|

- Refer to Data List Reference Table

. .

- Item No. 79: Barometric pressure sensor

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding  ). ).

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

Clean throttle body (throttle valve portion) (Refer to Clean throttle body (throttle valve portion) (Refer to  ). ).

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

Repair for intake of air from gaps in gasket, seals, etc. Repair for intake of air from gaps in gasket, seals, etc.

|

|

|

|

|

|

- Check injector for operating sound (Refer to

). ).

|

|

|

Q.

Can operating sound be heard?

|

|

|

Check the injector system of the defective

cylinder.

(Refer to Code No. P0201: No. 1 Injector System  ). ).

(Refer to Code No. P0202: No. 2 Injector System  ). ).

(Refer to Code No. P0203: No. 3 Injector System  ). ).

(Refer to Code No. P0204: No. 4 Injector System  ). ).

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

- Refer to Data List Reference Table

. .

- Item No. 8: Oxygen sensor (front)

- Item No. 9: Oxygen sensor (rear)

|

|

|

Q.

Are the check result normal?

|

|

|

Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code  ). ).

|

|

|

|

|

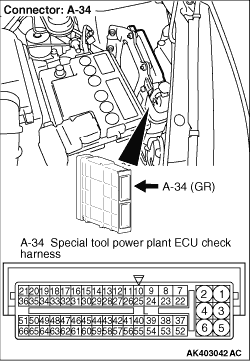

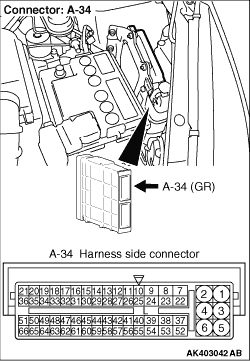

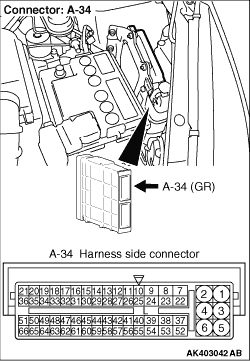

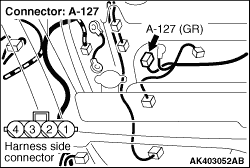

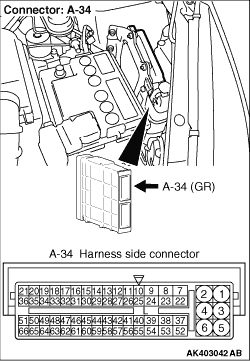

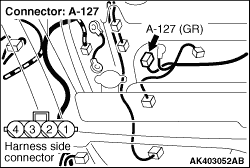

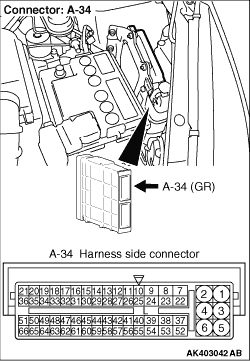

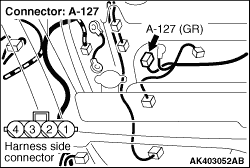

- Disconnect engine-ECU connector, and connect special tool power plant ECU

check harness (MB991987), and then measure the voltage on the check connector.

- Engine: Idling after warm-up

- Transmission: Neutral

- Cooling fan: Not operating

- Voltage between terminal No. 54 and earth.

OK: Switching the headlamps to ON from OFF causes the voltage to decrease.

Q.

Is the check result normal?

Go to Step 13 . Go to Step 13 .

Go to Step 10 . Go to Step 10 .

|

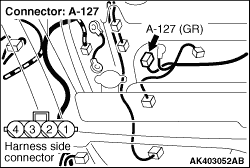

|

Q.

Is the check result normal?

Go to Step 11 . Go to Step 11 .

Repair or replace the connector. Repair or replace the connector.

|

|

- Check output line for open/short circuit and damage.

Q.

Is the check result normal?

Go to Step 12 . Go to Step 12 .

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

- After alternator is replaced, re-check for trouble symptom.

|

|

|

Q.

Does trouble symptom persist?

|

|

|

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding  ). ).

|

|

|

|

|

|

- Remove the spark plug and install to the ignition coil.

- Connect the ignition coil connector.

- Remove all injector connectors.

- At the engine start, check each spark plug procedure a spark.

|

|

|

Q.

Is the check result normal?

|

|

|

Check ignition circuit system (Refer to Inspection Procedure 24 Check ignition circuit system (Refer to Inspection Procedure 24  ). ).

|

|

|

|

|

|

- Check each injector for spray condition (Refer to

). ).

|

|

|

Q.

Is the check result normal?

|

|

|

- Check compression pressure (Refer to GROUP 11E - On-vehicle Service - Compression

Pressure Check

). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the compression pressure. Repair the compression pressure.

|

|

|

|

|

|

- Check purge control solenoid valve itself (Refer to GROUP 17 - Emission

Control System - Evaporative Emission Control System- Purge Control Solenoid Valve

Check

). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the purge control solenoid valve. Replace the purge control solenoid valve.

|

|

|

|

|

|

OK: Operating sounds of fuel pump can be heard.

|

|

|

Q.

Is the check result normal?

|

|

|

Check fuel pump system (Refer to inspection Procedure 22 Check fuel pump system (Refer to inspection Procedure 22  ). ).

|

|

|

|

|

|

- After engine-ECU is replaced, re-check for trouble symptom.

|

|

|

Q.

Does trouble system persist?

|

|

|

Check for foreign matters (water, kerosene, etc.) in fuel and replace if necessary. Check for foreign matters (water, kerosene, etc.) in fuel and replace if necessary.

|

|

|

|

Inspection chart for diagnosis code (Refer to

Inspection chart for diagnosis code (Refer to  ).

). Inspection chart for diagnosis code (Refer to

Inspection chart for diagnosis code (Refer to  ).

). Go to Step 2 .

Go to Step 2 . Go to Step 3 .

Go to Step 3 . Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code

Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code  ).

). Go to Step 4 .

Go to Step 4 . Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding  ).

). Go to Step 5 .

Go to Step 5 . Clean throttle body (throttle valve portion) (Refer to

Clean throttle body (throttle valve portion) (Refer to  ).

). Go to Step 6 .

Go to Step 6 . Repair for intake of air from gaps in gasket, seals, etc.

Repair for intake of air from gaps in gasket, seals, etc. Go to Step 7 .

Go to Step 7 .

Go to Step 8 .

Go to Step 8 . Align timing marks.

Align timing marks. Go to Step 9 .

Go to Step 9 . Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code

Perform the diagnosis code classified check procedure for the sensor that has

shown an abnormal data value (Refer to Inspection Chart for Diagnosis Code  ).

).

Go to Step 11 .

Go to Step 11 . Repair or replace the connector.

Repair or replace the connector.

Go to Step 12 .

Go to Step 12 . Repair the damaged harness wire.

Repair the damaged harness wire. Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding

Replace the engine-ECU then perform the variant coding (Refer to GROUP 00 - Precautions Before

Service - How to Perform Variant Coding  ).

). Check end.

Check end. Go to Step 14 .

Go to Step 14 . Check ignition circuit system (Refer to Inspection Procedure 24

Check ignition circuit system (Refer to Inspection Procedure 24  ).

). Go to Step 15 .

Go to Step 15 . Replace the injector.

Replace the injector. Go to Step 16 .

Go to Step 16 . Repair the compression pressure.

Repair the compression pressure. Go to Step 17 .

Go to Step 17 . Replace the purge control solenoid valve.

Replace the purge control solenoid valve. Go to Step 18 .

Go to Step 18 . Check fuel pump system (Refer to inspection Procedure 22

Check fuel pump system (Refer to inspection Procedure 22  ).

). Check for foreign matters (water, kerosene, etc.) in fuel and replace if necessary.

Check for foreign matters (water, kerosene, etc.) in fuel and replace if necessary. Check end.

Check end.