Pre-removal Operation

- Fuel Line Pressure Reduction (Refer to

). ).

- Strut Tower Bar Removal (Refer to GROUP 42, Strut Tower Bar

). ).

- Engine Cover Removal (Refer to GROUP 11E, Camshaft and Valve Stem Seal

). ).

- Air Cleaner Intake Duct, Air Cleaner Assembly and Air Cleaner Duct Assembly Removal (Refer

to GROUP 15, Air Cleaner

). ).

- Air Pipe B Removal (Refer to GROUP 15, Intercooler

). ).

|

Post-installation Operation

- Air Pipe B Installation (Refer to GROUP 15, Intercooler

). ).

- Air Cleaner Intake Duct, Air Cleaner Assembly and Air Cleaner Duct Assembly Installation (Refer

to GROUP 15, Air Cleaner

). ).

- Engine Cover Installation (Refer to GROUP 11E, Camshaft and Valve Stem Seal

). ).

- Strut Tower Bar Installation (Refer to GROUP 42, Strut Tower Bar

). ).

- Fuel Leakage Inspection.

|

|

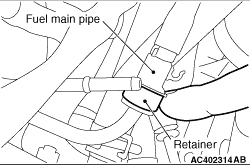

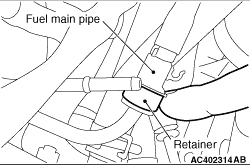

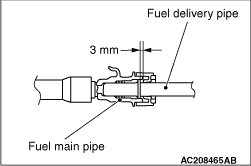

Raise the retainer, and pull out the fuel main pipe.

| note |

If the retainer comes off, install it securely after pulling out the fuel main pipe.

|

|

|

|

Remove the fuel delivery pipe with the fuel injector assembly attached to it.

|

|

|

1.

| caution |

Do not let the engine oil get into the fuel delivery pipe will be damaged.

|

Apply a drop of new engine oil to the O-ring.

|

|

|

2.Turn the fuel injector assembly and fuel pressure regulator to the right and left

to install to the fuel delivery pipe. Be careful not to damage the O-ring. After installing,

check that the item turns smoothly.

|

|

|

3.If it does not turn smoothly, the O-ring may be trapped, remove the item, re-install

it into the fuel delivery pipe and check again.

|

|

|

4.Tighten the fuel pressure regulator to the specified torque.

Tightening torque: 12 ± 1 N·m

|

|

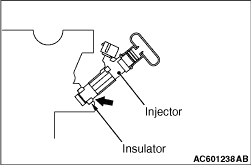

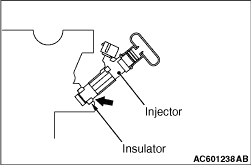

Be sure that there is no clearance between the insulator area and the injector, and install

them to the cylinder head.

|

|

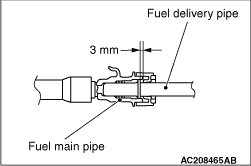

| caution |

After connecting the fuel main pipe, check that it has been securely installed by slightly

pulling in the removal direction. At this time, also check that there is approximately 3-mm play.

|

|

).

).