2.Verify that the operation sound increases with the engine speed.

| note | If the operating sound cannot be heard, inspect the injector actuation circuit. |

CHECK THE OPERATION SOUND |

|

MEASUREMENT OF RESISTANCE BETWEEN TERMINALS |

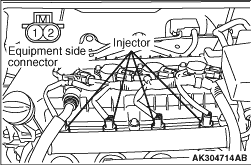

| 1.Disconnect the injector connector. |

| 2.Measure the resistance between terminals. Standard value:

10.5 - 13.5 Ω (at 20°C) <4A9> |

| 3.Connect the injector connector. |

CHECK THE INJECTION CONDITION |

1.Release the residual pressure in the fuel pipe line to prevent the fuel from running

out (Refer to  ). ). |

2.

|

| 3.Remove the injector. |

|

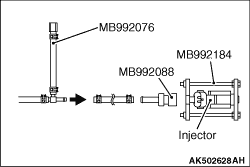

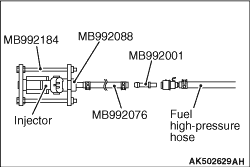

4.Prepare the special tool called injector test set (MB992076) as shown in the figure. (1) Disconnect the injector mounting hose. (2) Remove the adapter for mounting injector and attach the special tool Injector test nipple (MB992088) instead. (3) After attaching the injector on the special tool Injector test nipple (MB992088), secure it with the special tool injector holder (MB992184). 5.Mount the injector test set (MB992076) prepared with the special tool hose adapter (MB992001) onto the high-pressure fuel hose. 6.Connect the M.U.T.-III to the diagnosis connector. 7.Turn the ignition switch to the ON position. (But do not start the engine.) 8.Select "Item No. 5" of the M.U.T.-III actuator test to drive the fuel pump. |

|

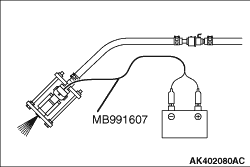

9.Connect the special tool Injector test harness (MB991607) between the injector and battery

to drive the injector. 10.Check each injector for spray conditions.The condition can be considered satisfactory unless it is extremely poor. 11.Stop the actuation of the injector, and check for leakage from the injector nozzle. Standard value: 1 drop or less per minute 12.After turning the ignition switch to the "LOCK" (OFF) position, remove the M.U.T.-III. 13.Actuate the injector until it does not spray fuel any longer, then drain the fuel inside the special tool. 14.Remove the special tool. 15.When the spray condition is extremely poor or any fuel leaks from the injector nozzle, replace the injector. 16.Replace the injector and high-pressure fuel hose in the original places. |