|

1.

| caution |

Beware that the operation sounds of other injectors can

be heard even if the injector that is being inspected might not be operating.

|

Use a stethoscope to listen to the operation sound (clicking) of the injectors while the

engine is idling or cranking.

2.Verify that the operation sound increases with the engine speed.

| note |

If the operating sound cannot be heard, inspect the injector actuation circuit.

|

|

|

|

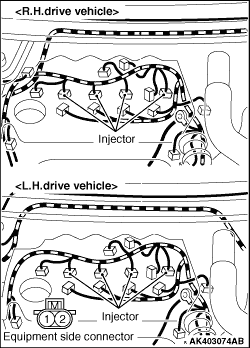

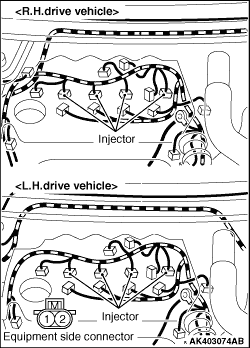

1.Disconnect the injector connector.

|

|

|

2.Measure the resistance between terminals.

Standard value: 10.5 - 13.5 Ω (at 20°C)

|

|

|

3.Connect the injector connector.

|

|

|

1.Following the steps below, bleed out the residual pressure within the fuel pipe line

to prevent flow of the fuel (Refer to  ). ).

|

|

|

2.Remove the fuel high-pressure hose at the delivery pipe side.

|

|

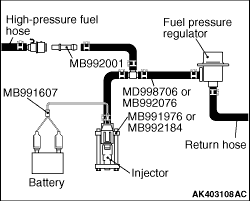

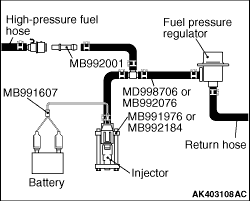

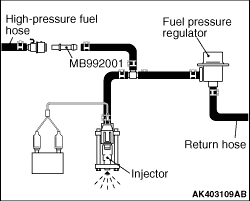

4.Assemble the following special tools as shown in Fig.

- Injector test set (MD998706)

- Injector test harness (MB991607 or MB992076)

- Hose adaptor (MB992001)

- Injector test holder assembly (MB991976 or MB992184)

5.Connect the M.U.T.-III to the diagnosis connector.

6.Turn the ignition switch to "ON" position (But do not start the engine).

7.Select "Item No. 5" from the M.U.T.-III actuator test to drive the fuel pump.

|

|

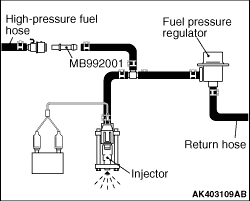

8.Activate the injector and check the atomized spray condition of the fuel.

The condition can be considered satisfactory unless it is extremely poor.

9.Stop the actuation of the injector, and check for leakage from the injector’s

nozzle.

Standard value: 1 drop or less per minute

10.Turn the ignition switch to "LOOK" (OFF) position and then disconnect M.U.T.-III.

11.Actuate the injector until the fuel cannot flow. Draw the fuel out from the special

tool.

12.Remove the special tool.

13.If the fuel spray condition is extremely poor or if there is the fuel leakage from

the injector nozzle, replace the injector.

14.Install the injector and high-pressure fuel hose.

|