|

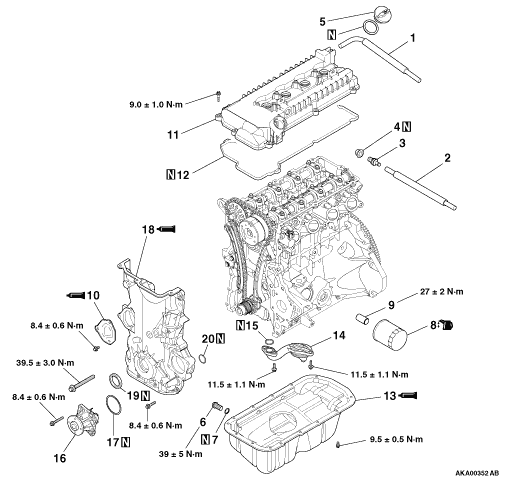

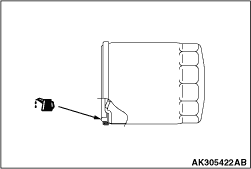

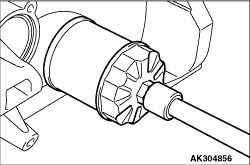

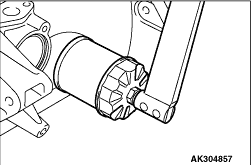

Remove the oil filter using an oil filter wrench (commercially available).

|

|

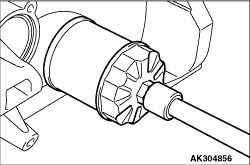

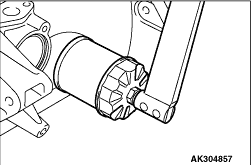

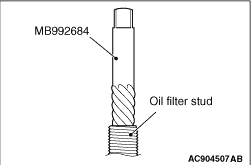

Remove the oil filter stud using the screw extractor (Recommended tool: MB992684), or

equivalent.

| note |

This recommended tool is a component of the screw extractor set (MB992678).

|

|

|

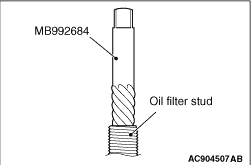

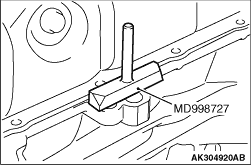

1.Remove the oil pan retaining bolts.

2.Knock the special tool Oil pan cutter (MD998727) between the oil pan and the cylinder

block.

|

|

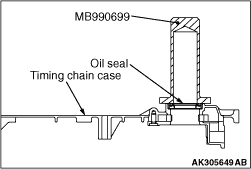

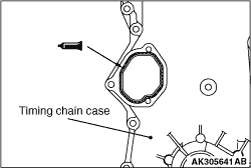

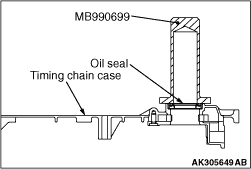

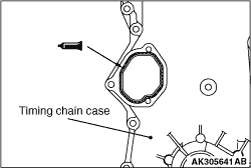

Install the front oil seal into the timing chain case using the special

tool Differential oil seal installer (MB990699).

|

|

|

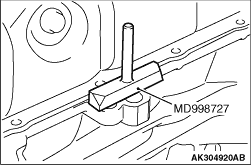

1.Remove any liquid gasket remaining on the timing chain case, the cylinder block, and

the cylinder head.

|

|

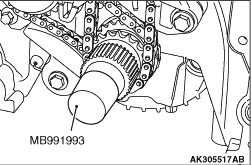

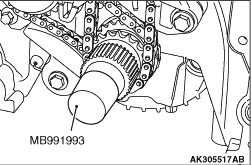

2.Install the special tool Oil seal guide (MB991993) onto the crankshaft.

|

|

3.

| caution |

The timing chain case should be installed within 3 minutes of

applying liquid gasket.

|

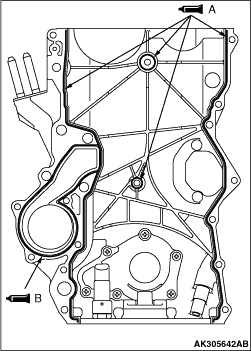

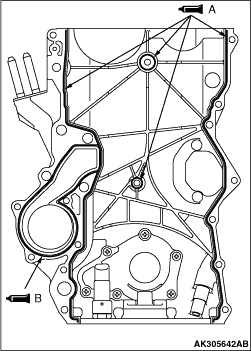

Apply a 2.0 ± 0.5 mm bead of liquid gasket to location A, and a 1.5 ± 0.5

mm bead of liquid gasket to location B on the timing chain case respectively as illustrated.

Specified sealant

A: Three bond 1217G or equivalent

B: Three bond 1227D or equivalent

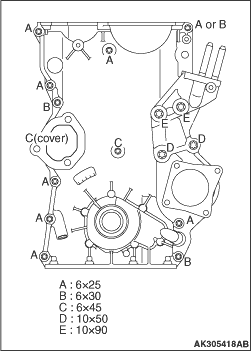

4.Install the timing chain case.

| note |

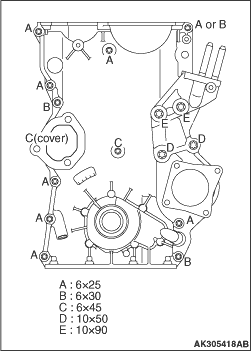

The retaining bolts have different lengths. Be sure to use the correct bolt for each location.

|

|

|

5.Tighten the chain case retaining bolts to the specified torques.

Tightening torque:

M6 8.4 ± 0.6 N·m

M10 (at support bracket) 39.5 ± 3.0 N·m

M10 (at brace) 36 ± 3.6 N·m

|

|

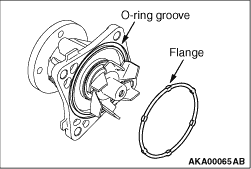

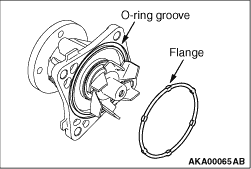

1.Carefully remove the coolant dry matters and the other foreign materials from the O-ring

groove of the water pump. In the same way, clean the timing chain case side.

2.Push the flange of the new O-ring into the O-ring groove of the water pump to securely

install the O-ring. Sufficiently apply water or the coolant to the O-ring with a brush so that the

O-ring does not fall.

3.Gently inverting the water pump, check whether the O-ring does not fall.

4.Install the water pump to the timing chain case. At that time, be careful that the

O-ring does not fall or the O-ring is not jammed.

|

|

|

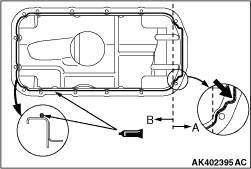

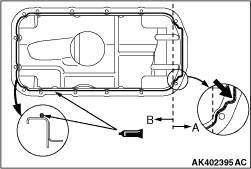

1.Remove any liquid gasket remaining on the cylinder block, the timing chain case, the

oil seal case and the oil pan.

| caution |

The oil pan should be installed within 3 minutes of applying

liquid gasket.

|

|

|

2.Apply a 4.0 ± 0.5 mm bead of liquid gasket to location A, and a 2.0 ± 0.5

mm bead of liquid gasket to location B on the oil pan respectively as illustrated.

Specified sealant:

Three bond 1217G or equivalent

3.Install the oil pan by tightening the fittings to 9.5 ± 0.5 N·m.

|

|

|

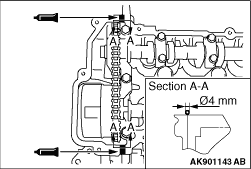

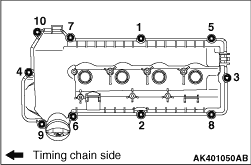

1.Remove any liquid gasket remaining on the cylinder head cover, the timing chain case

and the cylinder head.

|

|

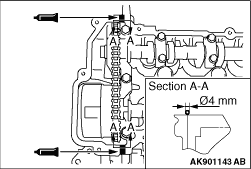

2.

| caution |

The timing chain should be installed within 3 minutes of applying

liquid gasket.

|

Apply a 4 mm bead of liquid gasket as illustrated.

Specified sealant:

Three bond 1217G or equivalent

|

|

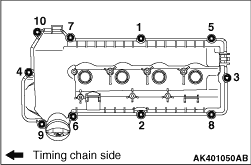

3.In accordance with the procedure shown in Figure, tighten the bolt of the cylinder head

cover to 9.0 ± 1.0 N·m.

|

|

|

1.Remove any liquid gasket remaining on the timing chain case and the cover.

|

|

2.

| caution |

The cover should be installed within 3 minutes of applying liquid

gasket.

|

Apply a 2.0 ± 0.5 mm bead of liquid gasket as illustrated.

Specified sealant:

Three bond 1217G or equivalent

|

|

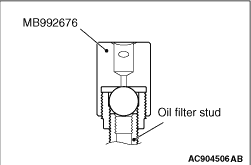

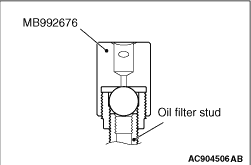

Using the special tool Oil filter stud setter (MB992676), install the new oil filter stud

and tighten it to the specified torque of 27 ± 2 N·m.

|

|

|

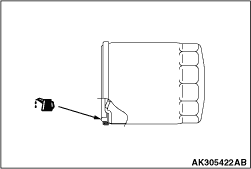

1.Clean the filter mounting surface on the cylinder block.

|

|

2.Apply engine oil to the oil filter gasket as shown in the drawing.

|

|

3.

| caution |

Tighten the oil filter using a filter wrench (commercially available).

Manual tightening cannot generate the required torque, leading to oil leakage.

|

Screw in the oil filter until the O-ring contacts the mounting surface. Further tighten

by 3/4 of a turn or to 11 ± 1 N·m using a filter wrench.

|