4.Install the crankshaft bearing cap carefully and tighten the bolts to the specified torque according to INSTALLATION SERVICE POINTS >>B<<

.

.5.Remove the bolts, then remove the crankshaft bearing cap carefully.

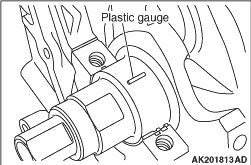

CRANKSHAFT OIL CLEARANCE (PLASTIC GAUGE METHOD) |

| This plastic gauge method is recommended as the simplest way of measuring the crankshaft

oil clearance. |

| Measure the crankshaft oil clearance using a plastic gauge as follows: |

| 1.Wipe off oil from the crankshaft journal surface and the crankshaft bearing inner

surface. |

| 2.Install the crankshaft. |

CYLINDER BLOCK |

| 1.Visually check the cylinder block for scratches, rust, and any other corrosion. Also

check it for cracks using a flaw detecting penetrant. If any defect is evident, replace the cylinder block. |

|

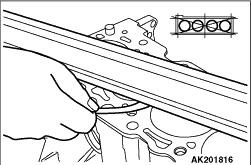

2.Use a straightedge and thickness gauge to check the cylinder block top surface for warp. If the warp exceeds the specified limit, correct by grinding. Make sure that the surface is free from remaining gasket material and other foreign matter. Standard value: 0.05 mm Limit: 0.1 mm Grinding limit: 0.2 mm 3.Check cylinder walls for scratches and seizure. If defects are evident, rebore to oversize or replace the cylinder block. |

|

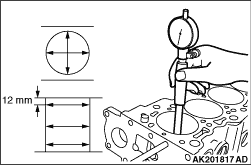

4.Use a cylinder gauge to measure the cylinder bore diameter and taper. If the cylinder is worn badly, rebore it to an oversize and replace the piston and piston rings with ones matched with the new bore size. The points at which the measurements should be made are indicated in the illustration. Standard value: 75.50 - 75.53 mm Taper: 0.01 mm |