|

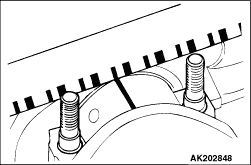

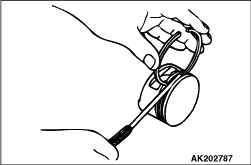

1.Measure the clearance between each piston ring and its groove. If the limit is exceeded,

replace the ring or piston, or both.

Standard values:

No. 1 ring 0.03 - 0.07 mm

No. 2 ring 0.02 - 0.06 mm

Limits: 0.1 mm

|

|

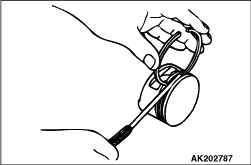

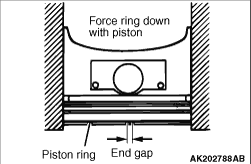

2.Install the piston ring into the cylinder bore and force it down with the head of the

piston until the ring becomes right-angled to the cylinder wall. Then, measure the end gap of the

ring with a thickness gauge. If the end gap is excessive, replace the piston ring.

Standard values:

No. 1 ring 0.15 - 0.30 mm

No. 2 ring 0.30 - 0.45 mm

Oil ring 0.20 - 0.50 mm

Limits:

No. 1 ring 0.8 mm

No. 2 ring 0.8 mm

Oil ring 1.0 mm

|

|

|

1.Wipe off oil from the crankshaft pin and connecting rod bearing.

|

|

|

2.Cut a piece of plastic gauge whose length is equivalent to the width of the bearing

and place it on the crankshaft pin in parallel with its axis.

|

|

|

3.Install the connecting rod cap carefully and tighten the nuts according to INSTALLATION

SERVICE POINTS >>G<< . .

|

|

|

4.Remove the nuts, then remove the connecting rod cap carefully.

|

|

5.Measure the largest width of the crushed plastic gauge using the ruler printed on the

bag of the plastic gauge.

Standard value: 0.025 - 0.040 mm

Limit: 0.1 mm

|

.

.