|

|

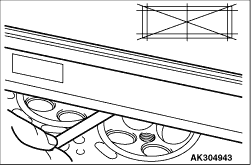

1.Before cleaning, check the cylinder head for leakage of coolant or exhaust gas as

well as cracks or other damage.

|

|

|

2.Remove oil, scale, sealant, carbon and other residues completely. Clean the oil passages

and blow compressed air through them to verify that they are free of restriction.

|

|

3.

| caution |

The grinding limit for the cylinder head and block combined

is 0.2 mm.

|

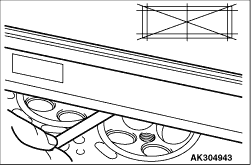

Using a straight edge and a thickness gauge, measure the flatness of the cylinder head

bottom surface. If the distortion exceeds the limit, correct it by grinding.

Bottom face distortion

Standard value: 0.03 mm max.

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new part): 113.0 mm

|

|

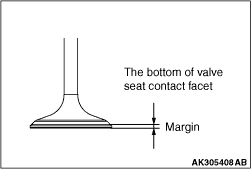

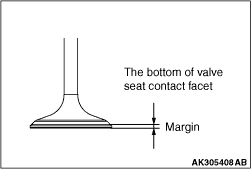

1.If the valve face-to-seat contact is uneven or interrupted, correct the valve seat.

2.Measure the valve head margin. If the measured value exceeds the limit, replace with

a new valve.

Standard value:

Intake 1.35 mm

Exhaust 1.85 mm

Limit:

Intake 0.85 mm

Exhaust 1.35 mm

|

|

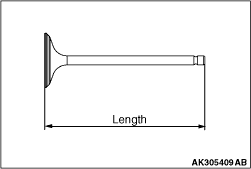

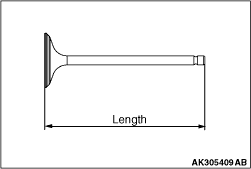

3.Measure the valve overall length. If the measured value exceeds the limit, replace with

a new valve.

Standard value:

Intake 89.61 mm

Exhaust 90.94 mm

Limit:

Intake 89.11 mm

Exhaust 90.44 mm

|

|

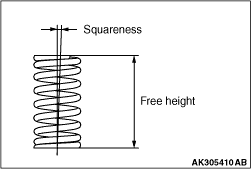

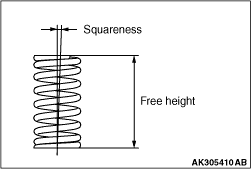

1.Measure the valve spring free height. If the measured value exceeds the limit, replace

with a new spring.

Standard value: 43.1 mm

Limit: 42.1 mm

2.Measure the valve spring out-of-squareness. If the measured value exceeds the limit,

replace with a new spring.

Standard value: 2° or less

Limit: 4°

|

|

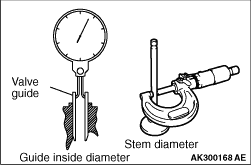

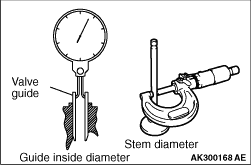

Measure the clearance between the valve guide and the valve stem. If the measured value

exceeds the limit, replace the valve guide or the valve, or both.

Standard value:

Intake 0.020 - 0.047 mm

Exhaust 0.030 - 0.057 mm

Limit:

Intake 0.10 mm

Exhaust 0.15 mm

|

|

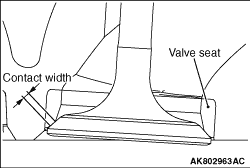

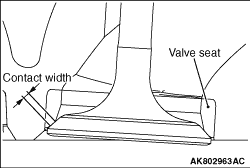

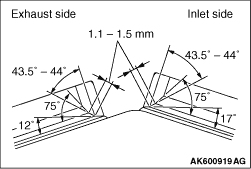

Assemble the valve, then measure the contact width. If the measurement exceeds the specified

limit, replace or correct the valve seat.

Standard value: 1.1 - 1.5 mm

| caution |

If the variation in the width exceeds 0.2 mm even if the contact width is

within the standard value, replace or correct the valve sheet.

|

|

|

|

1.Check clearance between valve guide and valve and replace the valve guide if necessary

before repairing the valve seat.

|

|

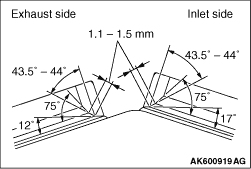

2.Repair the valve seat so that seat width and seat angle can become the specified shape.

3.Smear a lapping compound on the valve and valve seat after the repair. Fit the valve

into the valve seat.

|

|

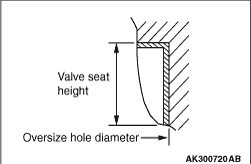

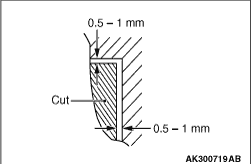

1.Scrape the valve seat to be replaced from inside. Make its wall thickness thin before

pulling out.

|

|

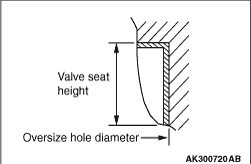

2.Repair the valve seat hole of the cylinder head to match it with the diameter of the press

fit oversize valve seat.

Inlet valve seat bore diameter

0.3 O.S.: 31.83 - 31.85 mm

Exhaust valve seat bore diameter

0.3 O.S.: 28.32 - 28.34 mm

3.Press fit the valve seat, paying attention not to score the cylinder head inner diameter

at room temperature.

4.Ream the valve seat.

Refer to “Repair procedures of valve seat."

|

|

|

1.Pull out the valve guide with a press toward the cylinder block side.

|

|

|

2.Ream the valve guide hole of the cylinder head to match it with the press fit oversize

valve guide.

| caution |

Do not use a valve guide with the same size as the pulled out

valve guide because it cannot be press fitted.

|

Valve guide bore diameter

0.05 O.S.: 10.55 - 10.57 mm

|

|

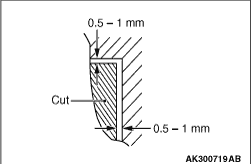

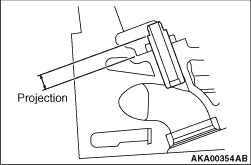

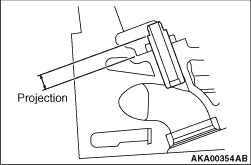

3.Press fit the valve guide to the illustrated dimension.

Standard value: 7.7 - 8.3 mm

| note |

Press fit the valve guide from the cylinder head top surface.

|

4.After pressing fit the valve guide, insert a new valve to check for sliding.

|