|

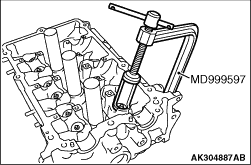

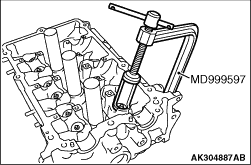

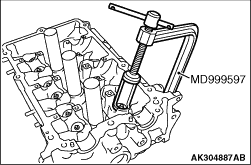

While compressing the valve spring using the special tool Valve spring compressor (MD999597),

remove the retainer lock.

| note |

To facilitate reassembly, the valve, spring and other parts removed should be kept together

and attached with a tag showing where it has been assembled including the cylinder number.

|

|

|

|

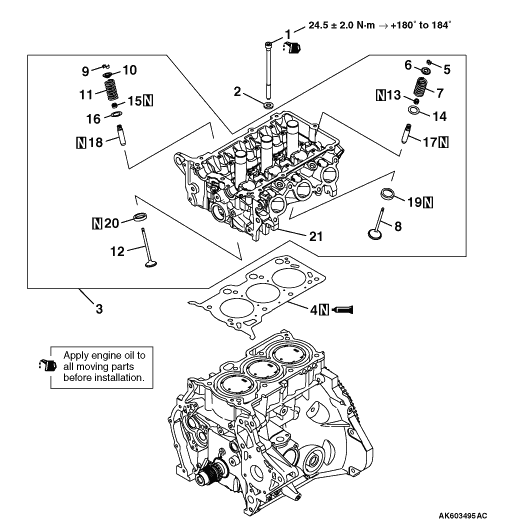

1.Install the valve spring seat.

|

|

|

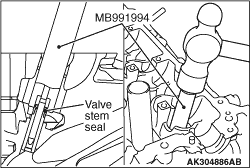

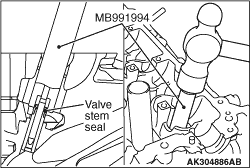

2.

| caution |

- The valve stem seal

should not be reused.

- A new valve stem seal should be installed correctly using the special tool. Incorrectly

installed valve stem seal will allow engine oil to leak through into the combustion chamber.

|

Lightly coat a new valve stem seal with engine oil.

|

|

3.Insert the new valve stem seal into the valve guide using the special tool Valve stem

seal installer (MB991994).

| note |

Use the special tool, on which the number "MB991994A" is stamped.

|

|

|

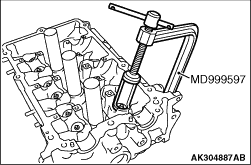

While compressing the valve spring using the special tool Valve spring compressor (MD999597),

install the retainer lock.

|

|

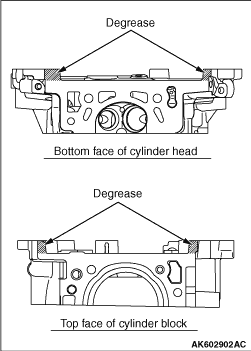

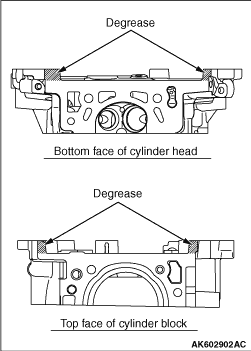

1.Completely remove the liquid gasket on the upper plane of the cylinder block and the lower

plane of the cylinder head.

2.

| caution |

Sufficiently check that there is no residual oil on the

place where degreasing is performed. If fingerprints are left, do not touch it with bare hands

after the degreasing, since the oils from your fingers will harm the seal ability.

|

Degrease the place specified in the illustration.

|

|

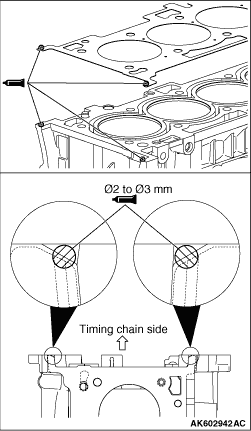

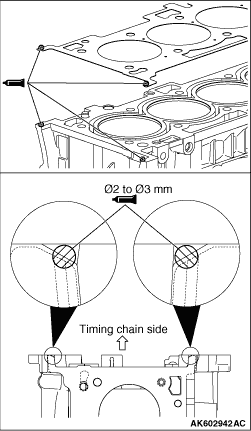

3.As shown in the illustration, apply a 2.5 ± 0.5 mm of sealant to the top face

of cylinder block.

Specified sealant:

Three bond 1217G or equivalent

4.Install the cylinder head gasket.

| note |

Check that the centre of the liquid gasket is located toward the cylinder gasket in the

position specified in the illustration.

|

5.As shown in the illustration, apply a 2.5 ± 0.5 mm of sealant to the top

face of cylinder head gasket.

Specified sealant:

Three bond 1217G or equivalent

6.Install the cylinder head assembly.

|

|

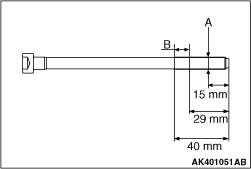

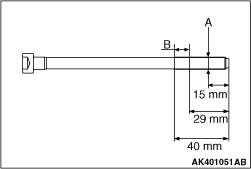

1.Inspect all reused cylinder bolts according to the following procedure.

(1)

Measure the outside diameter shown in the illustration (arrow "A").

(2)

Measure the smaller outside diameter shown in the illustration (arrow "B").

(3)

When the difference between the smaller outside diameters (arrow "A" and "B") exceeds

the standard value, replace the cylinder head bolt.

Standard value: 0 - 0.15 mm

2.Install the cylinder head bolt and washer onto the cylinder head.

|

|

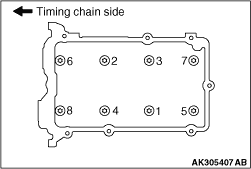

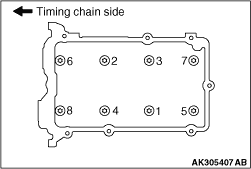

3.In accordance with the installation order, tighten them to the specified torque of 24.5 ± 2

N·m in several steps.

4.Make sure all bolts reach the specified torque.

|

|

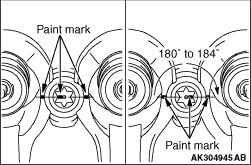

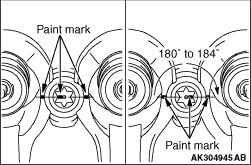

5.Put paint marks on the bolt heads and the cylinder as illustrated.

6.

| caution |

- If the head bolt is

tightened less than the specified lower limit of 180 degree angle, the bolt may become loose.

Be sure to tighten correctly.

- If the head bolt is tightened in excess of the specified upper limit of 184 degree

angle, loosen the bolt completely and repeat the entire procedures.

|

Tighten the bolts in the correct sequence by 180 to 184 degree angle.

Ensure that the paint marks on the bolt heads and the cylinder are aligned in a straight

line.

|