|

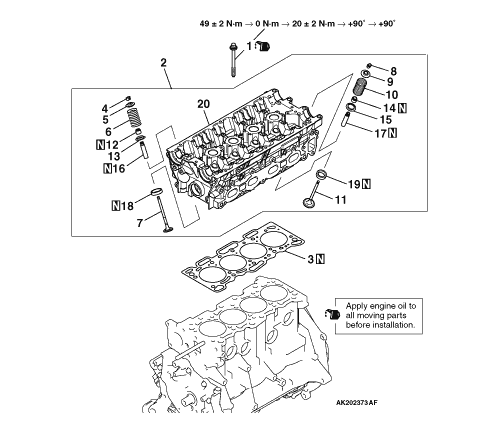

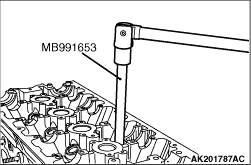

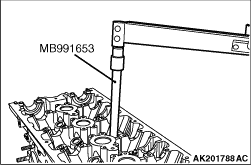

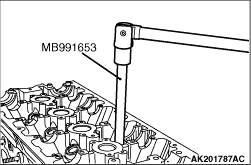

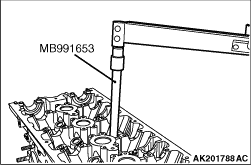

Use the special tool Cylinder head bolt wrench (MB991653) to loosen the cylinder head

bolts.

|

|

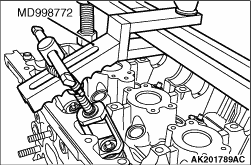

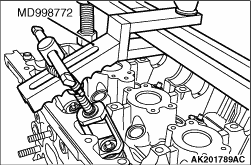

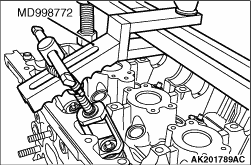

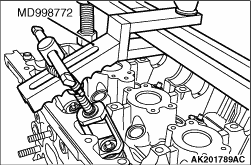

Compress the valve spring using the special tool Valve spring compressor

(MD998772), then remove the retainer lock.

| note |

Store removed valves, springs and other parts, after putting to each of them a tag that

identifies its cylinder No. or installation location.

|

|

|

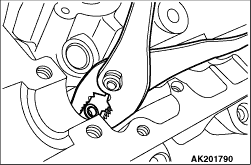

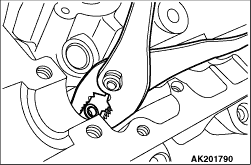

Using pliers, remove the valve stem seal.

|

|

|

1.Install the valve spring seat.

|

|

|

3.Apply a thin coat of engine oil to a new valve stem seal.

|

|

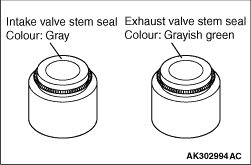

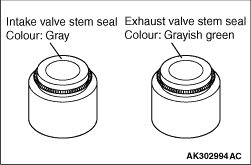

4.

| note |

Do not confuse the stem seals for intake valves with those for exhaust valves.

|

|

|

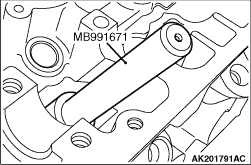

5.

| caution |

- Do not reuse the valve stem seal.

- The special tool must always be used when installing the valve stem

seal. Improper installation could result in oil leaks past the valve guide.

|

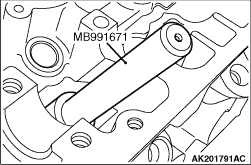

Use the special tool Valve seal installer (MB991671) to install the stem seal on the valve

guide. Use the stem of the valve to guide the stem seal.

|

|

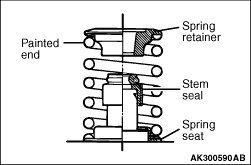

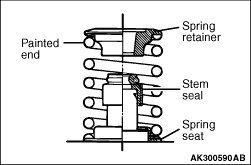

Install each valve spring with the painted end toward the rocker arm.

|

|

Compress the valve spring using the special tool Valve spring compressor (MD998772), then

install the retainer lock.

|

|

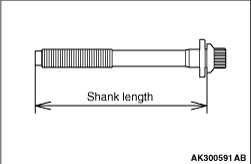

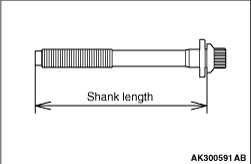

1.When reusing a cylinder head bolt, check that its nominal length (shank length) is not

greater than the limit. If the limit is exceeded, replace the bolt.

Limit: 103.2 mm

2.Apply engine oil to the threads and washer of the bolt.

|

|

3.

| note |

Use the special tool Cylinder head bolt wrench (MB991653) to tighten the bolts.

|

|

|

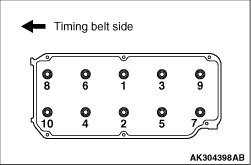

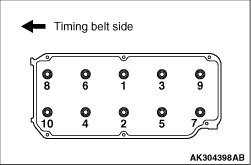

4.Tighten the bolts to 49 ± 2 N·m in the indicated sequence.

5.Loosen all the bolts completely.

6.Tighten the bolts again to a torque of 20 ± 2 N·m in the indicated

sequence.

|

|

7.

| caution |

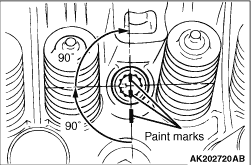

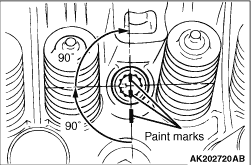

- If the tightening angle

is smaller than 90°, proper fastening performance could not be assured. Be sure to

respect that angle.

- If the bolt is tightened to an angle greater than the specified angle, loosen the

bolt completely and then retighten it beginning with the first step.

|

Make paint marks on each bolt’s head and on the cylinder head.

8.Turn the bolts 90° in the tightening direction and in the indicated sequence.

9.Give another 90° turn in the tightening direction to each bolt, making sure

that the paint mark on the bolt head and that on the cylinder head are on the same line.

|