|

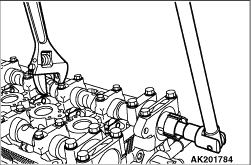

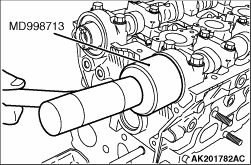

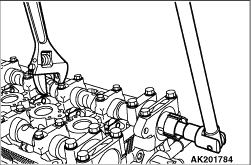

Holding the hexagonal portion of the camshaft with a wrench, remove the

cam position sensing cylinder.

|

|

|

While using care not to spill diesel fuel in the lash adjuster, install

the lash adjuster on the rocker arm.

|

|

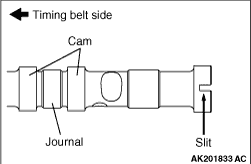

| caution |

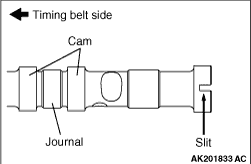

- Do not confuse intake and exhaust camshafts.

- A 4 mm slit is on the rear end of the intake camshaft.

|

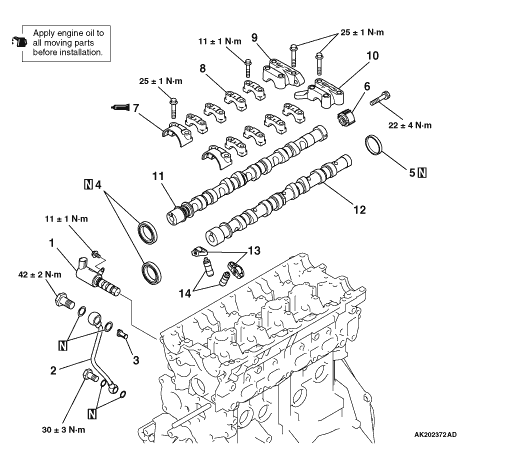

Apply engine oil to the camshaft journal and cams before installation.

|

|

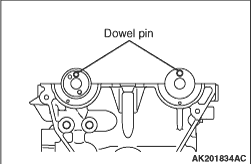

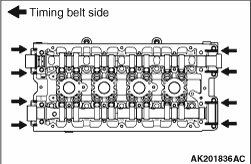

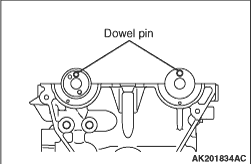

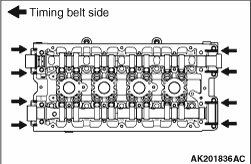

1.Place the dowel pins of the camshafts in the positions shown in the illustration.

| note |

By getting the dowel pins into position shown in the illustration, the camshaft slots

of tightening the cylinder head bolt are put in position.

|

|

|

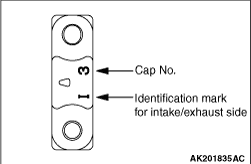

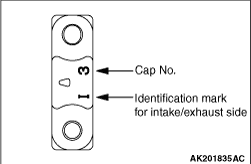

2.The bearing caps No. 2 to 5 are identical in shape. Before installation, be sure to check

the cap numbers and identification marks so that right bearing caps are installed in right places.

Identification marks (Die-stamped on front and No.

2 to 5 bearing caps)

I: Intake side

E: Exhaust side

3.Completely remove existing sealant from the bearing caps and cylinder head.

|

|

4.Apply specified sealant to the cylinder head at the points shown in the illustration.

Specified sealant:

Three bond 1212D or equivalent

5.Install the bearing caps in position and tighten bolts increasingly by giving turns

2 to 3 times each.

| note |

Completely wipe off excess of applied sealant that comes out.

|

6.Finally, tighten the bearing cap bolts to a specified torque.

Specified torque

Front bearing cap: 25 ± 1 N·m

Bearing cap: 11 ± 1 N·m

Rear right bearing cap: 25 ± 1 N·m

Rear left bearing cap: 25 ± 1 N·m

7.Check that the rocker arms are installed in position.

|

|

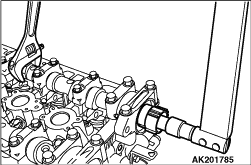

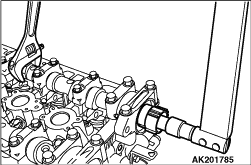

Holding the hexagonal portion of the camshaft, tighten the cam position

sensing cylinder to a specified torque of 22 ± 4 N·m.

|

|

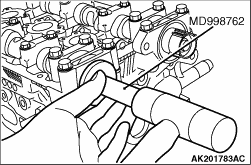

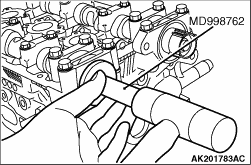

Using the special tool Circular packing installer (MD998762), install

the circular packing into the cylinder head.

|

|

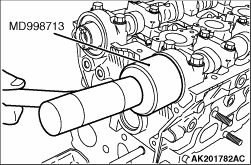

Using the special tool Oil seal installer (MD998713), install the oil

seal into the cylinder head.

|

|

|

1.

| caution |

Check the filter for foreign matters, damage and deformation

before installation.

|

|

|

|

1.Apply a small amount of engine oil to the o-ring of the oil feeder control valve.

|

|

|

2.Install the oil feeder control valve to the cylinder head.

|

|

|

3.Tighten the oil feeder control valve bolt to the specified torque of 11 ± 1

N·m.

|