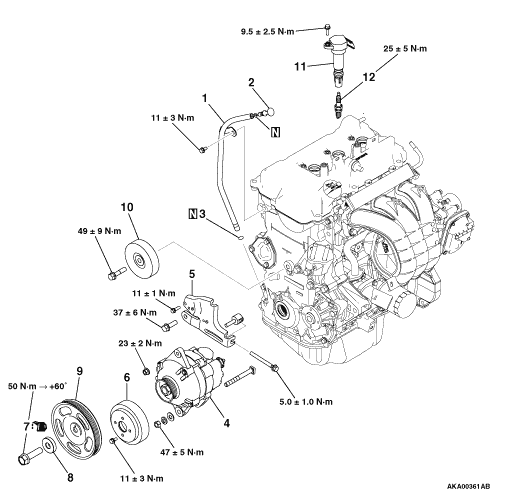

|

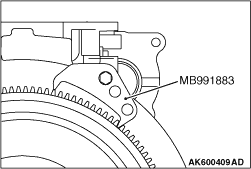

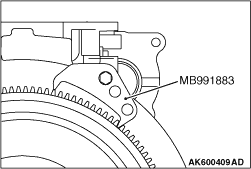

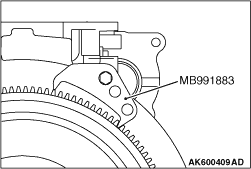

1.Lock the flywheel with the special tool Flywheel stopper (MB991883).

2.Remove the crankshaft bolt.

|

|

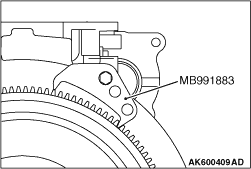

1.Lock the flywheel with the special tool Flywheel stopper (MB991883).

|

|

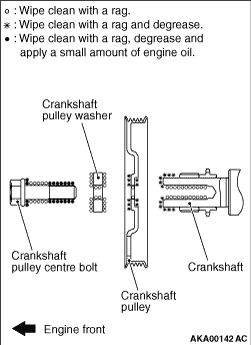

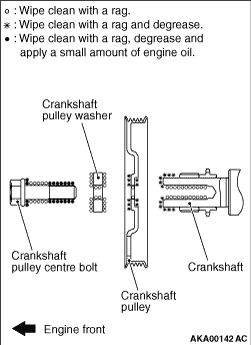

2.Using a rag, wipe dirt on the crankshaft thread hole and the crankshaft pulley washer.

3.Using a rag, wipe dirt on the crankshaft pulley and then degrease the place specified

in the illustration.

| note |

Perform degreasing to prevent the friction resistance from decreasing in the compressed

area due to the residual oil.

|

4.Install the crankshaft pulley.

5.Apply the minimum amount of engine oil to the crankshaft bolt threads and the seating

surface.

6.Tighten the crankshaft bolt to the specified torque of 50 N·m.

|

|

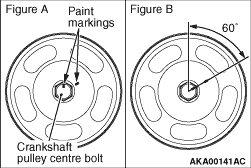

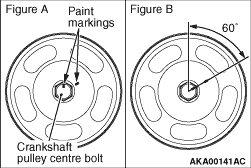

7.As shown in figure A, put a paint mark on one angle of the crankshaft pulley centre bolt.

Then, put a paint mark on the crankshaft damper pulley on the extended line of the angle next

to the marked angle.

8.

| caution |

- When the tightening

angle is smaller than the specified tightening angle, the appropriate tightening capacity cannot

be secured.

- When the tightening angle is larger than the specified tightening angle, remove

the bolt to start from the beginning again according to the procedure.

|

Tighten the crankshaft pulley centre bolt in a 60°, and check that the paint

mark on the crankshaft pulley centre bolt aligns with the paint mark on the crankshaft damper

pulley as shown in figure B.

|