|

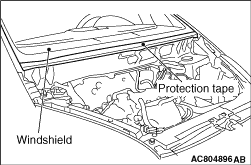

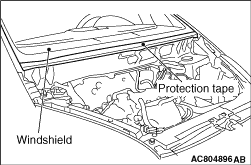

After removing the cowl top panel, attach a protection tape for the windshield on the

lower area of the windshield.

|

|

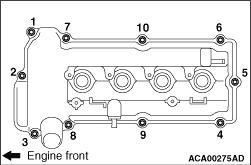

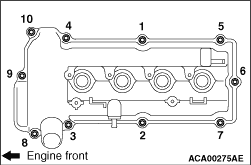

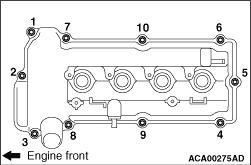

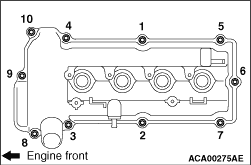

Loosen the cylinder head cover assembly mounting bolts in the order of the numbers shown

in the illustration.

|

|

1.

| caution |

Never turn the crankshaft anti-clockwise.

|

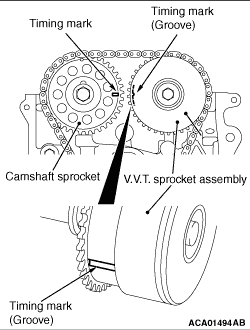

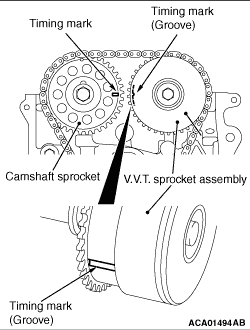

Turn the crankshaft clockwise, and align the timing mark of the camshaft sprocket (2 conceive

areas in front of the camshaft sprocket) and that of the V.V.T. sprocket assembly (the groove

of V.V.T. sprocket assembly side face). Then set No.1 cylinder to the TDC.

|

|

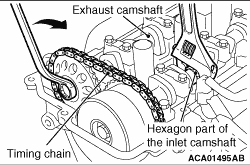

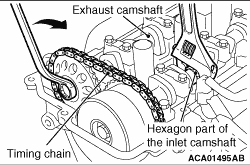

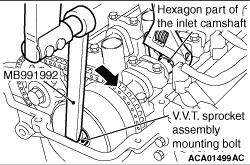

2.While holding the inlet camshaft hexagonal area with a wrench or a similar tool, slightly

turn the exhaust camshaft clockwise to tighten the timing chain at the timing chain tensioner

side and shorten the plunger of the timing chain tensioner.

|

|

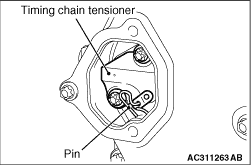

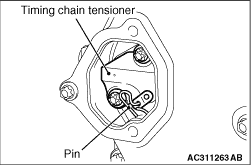

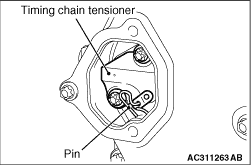

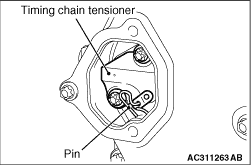

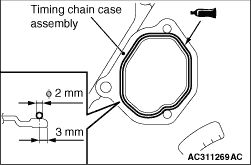

3.With the plunger of the tensioner shortened, insert a pin or a similar tool (3 mm or less

in diameter) to the hole shown in the illustration of the timing chain tensioner.

4.

| caution |

Do not turn the crankshaft after removing the timing

chain tensioner.

|

Loosen the timing chain tensioner mounting bolts, and remove the timing chain tensioner

from the timing chain case hole.

|

|

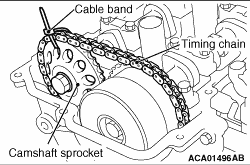

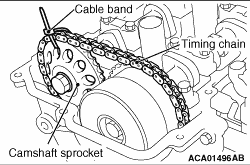

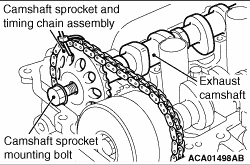

1.Fix the camshaft sprocket and the timing chain using a cable band or a similar tool.

|

|

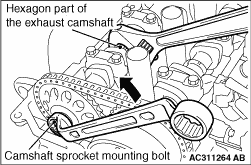

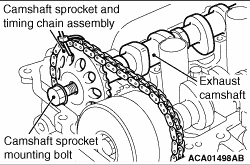

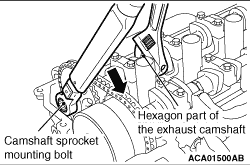

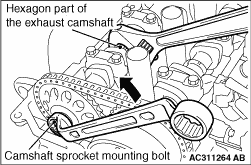

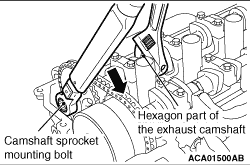

2.While holding the exhaust camshaft hexagonal area with a wrench or a similar tool, loosen

the camshaft sprocket mounting bolt.

|

|

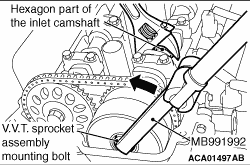

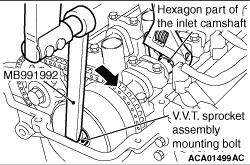

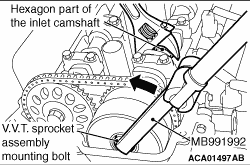

3.While holding the inlet camshaft hexagonal area using a wrench or a similar tool, use

special tool torque wrench adapter (MB991992) to loosen the V.V.T. sprocket assembly mounting

bolt.

|

|

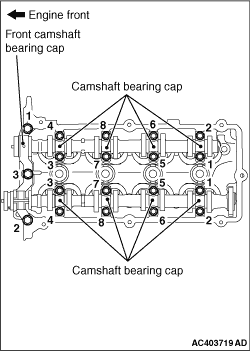

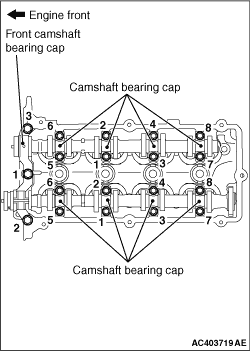

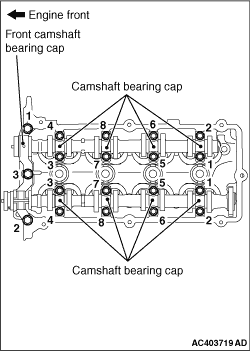

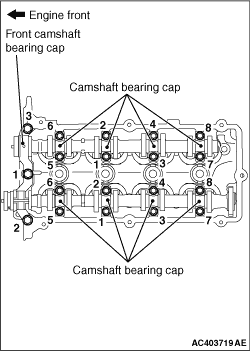

4.Loosen the front camshaft bearing cap mounting bolts, and then loosen each camshaft bearing

cap mounting bolts in the order shown. Remove the front camshaft bearing cap and each camshaft

bearing cap.

|

|

5.

| caution |

Do not turn the crankshaft after removing the camshaft sprocket

assembly with the timing chain.

|

Slightly raise the exhaust camshaft with the camshaft sprocket and timing chain assembly

from the cylinder head, remove the camshaft sprocket mounting bolt, and disconnect the camshaft

sprocket and timing chain assembly from the exhaust camshaft.

6.In the same way as step 5, disconnect the V.V.T. sprocket assembly and timing chain

assembly from the inlet camshaft.

7.

| caution |

After disconnecting the camshaft sprocket and the V.V.T. sprocket

assembly (with the timing chain for each) from the camshaft, do not dislocate the camshaft sprocket,

the V.V.T. sprocket assembly, and the timing chain.

|

After removal, place the camshaft sprocket and timing chain assembly, and the V.V.T. sprocket

assembly and timing chain assembly on the timing chain case assembly

|

|

|

1.Cover the oil groove of the oil control valve with a cardboard.

|

|

|

2.

| caution |

When installing the O-ring to the oil control valve,

take care not to damage the O-ring.

|

Apply the engine oil to the O-ring and install it to the oil control valve.

|

|

|

3.

| caution |

When installing the oil control valve to the cylinder

head, take care not to damage the O-ring.

|

Apply the engine oil to the O-ring and install the oil control valve to the cylinder head.

|

|

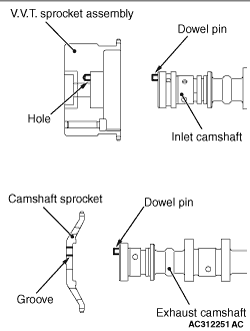

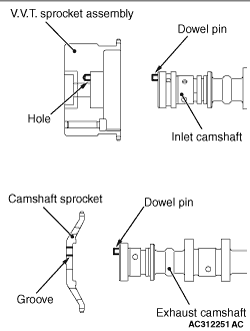

1.First, lift the V.V.T. sprocket assembly side of the camshaft sprocket, V.V.T. sprocket

assembly and the timing chain assembly. Then align the dowel pin of the inlet camshaft with the

V.V.T. sprocket assembly hole, and assemble the inlet camshaft and the V.V.T. sprocket assembly.

Temporarily tighten the mounting bolt.

2.Next, lift the camshaft sprocket side of the camshaft sprocket, V.V.T. sprocket assembly

and the timing chain assembly. Then align the dowel pin of the exhaust camshaft with the camshaft

sprocket groove, and assemble the exhaust camshaft and the camshaft sprocket. Temporarily tighten

the mounting bolt.

3.Place the inlet camshaft and exhaust camshaft on the installing location of the cylinder

head.

|

|

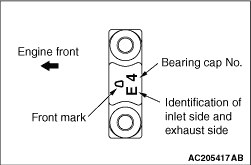

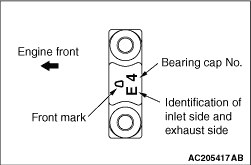

4.Camshaft bearing caps (No.2 to 5) are identical. To avoid confusion (bearing cap No. and

inlet/exhaust side), confirm each identification mark and face the front mark towards

the direction shown before installing them.

Identification mark (engraved on the front and bearing caps No.2 - 5)

I: Inlet side

E: Exhaust side

|

|

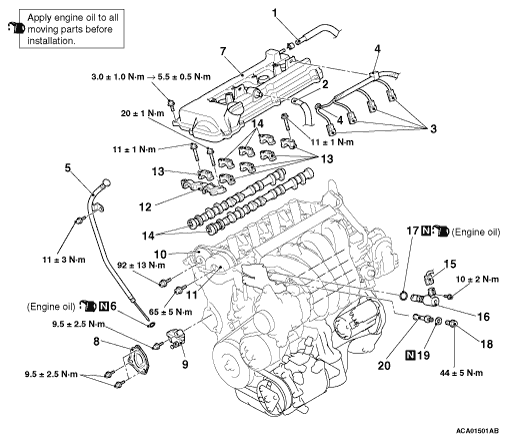

5.Tighten each camshaft bearing cap mounting bolts to the specified torque in the order

shown, and then tighten the front camshaft bearing cap mounting bolts as well.

Tightening torque:

11 ± 1 N·m (Camshaft bearing cap

mounting bolts)

20 ± 1 N·m (Front camshaft bearing cap mounting bolts)

|

|

6.While holding the inlet camshaft hexagonal area using a wrench or a similar tool, use

special tool torque wrench adapter (MB991992) to tighten the V.V.T. sprocket assembly mounting

bolt to the specified torque. Since the V.V.T. sprocket assembly mounting bolt is tightened

by special tool (MB991992), calculate the tightening torque by the following formula.

Tightening torque: (65 ± 5) × {L ÷ (L + 150)} N·m

65 ± 5: Tightening torque of the V.V.T. sprocket assembly

mounting bolt (unit: N·m)

L: Distance between the centre of a torque wrench drive and of its handle (unit:

mm)

150: Length of special tool (unit: mm)

|

|

7.While holding the exhaust camshaft hexagonal area using a wrench or similar tool, tighten

the camshaft sprocket mounting bolt to the specified torque.

Tightening torque: 92 ± 13 N·m

|

|

1.Install the timing chain tensioner with the pin or the similar tool to the cylinder block

through the timing chain case hole, and tighten the timing chain tensioner mounting bolts to

the specified torque.

Tightening torque: 9.5 ± 2.5 N·m

2.Pull out the pin or the similar tool of the timing chain tensioner.

|

|

|

1.Remove the sealant from the installation face of the timing chain tensioner cover

and the timing chain case assembly.

|

|

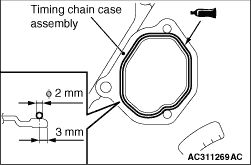

2.Apply a bead of the specified sealant to the mating surface of the timing chain case assembly.

Specified sealant: ThreeBond 1217G or equivalent

| note |

Install the timing chain case cover immediately after applying sealant.

|

|

|

|

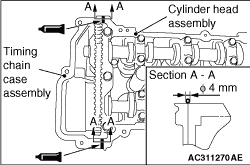

1.Remove the sealant from the cylinder head cover assembly and the matching area of

the cylinder head assembly and the timing chain case assembly.

|

|

2.

| caution |

After the installation, until a sufficient period of time (one hour or

more) elapses, do not apply the oil or water to the sealant application area or start the engine.

|

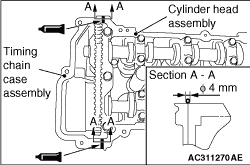

Apply sealant to the joint between the cylinder head and timing chain case assembly as

shown in the figure and install the cylinder head cover assembly to the cylinder head.

Specified sealant: ThreeBond 1217G or equivalent

| note |

Install the cylinder head cover assembly immediately after the application of sealant.

|

|

|

3.Tighten the cylinder head cover assembly mounting bolts to the specified torque in the

order of the numbers shown in the illustration.

Tightening torque: 3.0 ± 1.0 N·m

4.Tighten again the cylinder head cover assembly mounting bolts to the specified torque

in the order of number shown in the figure.

Tightening torque: 5.5 ± 0.5 N·m

|