|

|

|

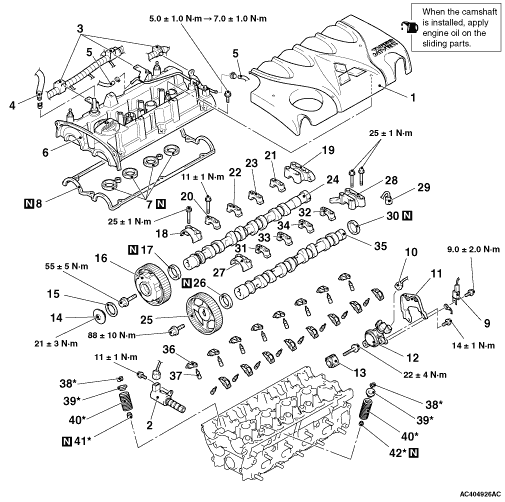

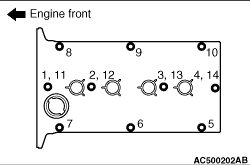

Removal steps

|

|

|

1.

|

Engine cover

|

|

>>N<<

|

2.

|

Oil feeder control valve

|

|

|

·

|

Ignition coil (Refer to GROUP 16, Ignition System - Ignition

Coil  ). ).

|

|

|

3.

|

Control wiring harness clamp

|

|

|

4.

|

Rocker cover PCV hose connection

|

|

|

5.

|

Vacuum hose connection

|

|

>>M<<

|

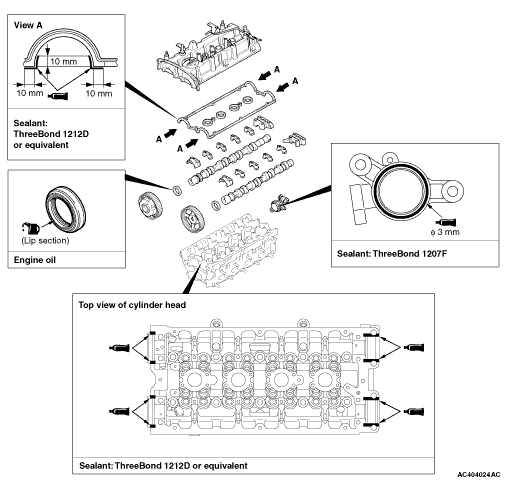

6.

|

Rocker cover assembly

|

|

|

7.

|

Spark plug guide oil seal

|

|

|

8.

|

Rocker cover gasket

|

|

|

9.

|

Noise condenser

|

|

|

10.

|

Camshaft position sensor connector connection

|

|

|

11.

|

Air intake pipe bracket

|

|

>>L<<

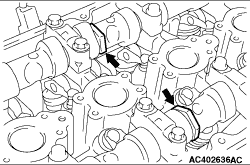

|

12.

|

Camshaft position sensor support

|

|

>>K<<

|

13.

|

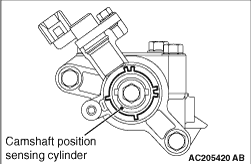

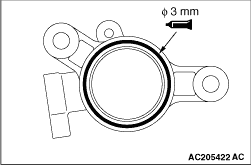

Camshaft position sensing cylinder

|

<<A>>

|

|

14.

|

Camshaft sprocket cap

|

|

|

15.

|

Washer

|

<<B>>

|

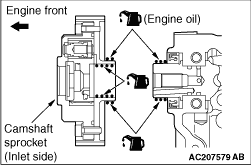

>>J<<

|

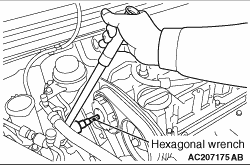

16.

|

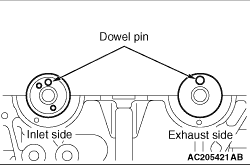

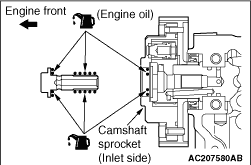

Camshaft sprocket (inlet side)

|

|

>>H<<

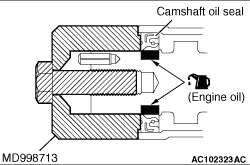

|

17.

|

Camshaft oil seal

|

|

>>F<<

|

18.

|

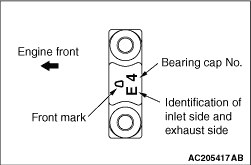

Camshaft bearing cap, front

|

|

>>F<<

|

19.

|

Camshaft bearing cap, rear right

|

|

>>F<<

|

20.

|

Camshaft bearing cap, No.2

|

|

>>F<<

|

21.

|

Camshaft bearing cap, No.5

|

|

>>F<<

|

22.

|

Camshaft bearing cap, No.3

|

|

>>F<<

|

23.

|

Camshaft bearing cap, No.4

|

|

>>E<<

|

24.

|

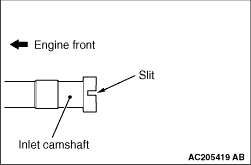

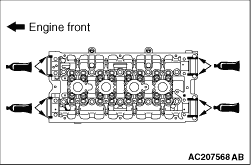

Inlet camshaft

|

<<B>>

|

>>I<<

|

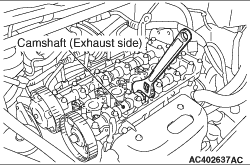

25.

|

Camshaft sprocket (exhaust side)

|

|

>>H<<

|

26.

|

Camshaft oil seal

|

|

>>F<<

|

27.

|

Camshaft bearing cap, front

|

|

>>F<<

|

28.

|

Camshaft bearing cap, rear left

|

|

|

29.

|

Waste gate solenoid valve connector connection

|

|

>>G<<

|

30.

|

Cylinder head camshaft end seal

|

|

>>F<<

|

31.

|

Camshaft bearing cap, No.2

|

|

>>F<<

|

32.

|

Camshaft bearing cap, No.5

|

|

>>F<<

|

33.

|

Camshaft bearing cap, No.3

|

|

>>F<<

|

34.

|

Camshaft bearing cap, No.4

|

|

>>E<<

|

35.

|

Exhaust camshaft

|

|

|

36.

|

Rocker arm

|

|

>>D<<

|

37.

|

Rocker arm lash adjuster

|

<<C>>

|

>>C<<

|

38.

|

Valve spring retainer lock

|

|

|

39.

|

Valve spring retainer

|

|

>>B<<

|

40.

|

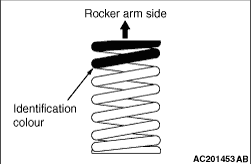

Valve spring

|

|

>>A<<

|

41.

|

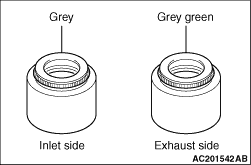

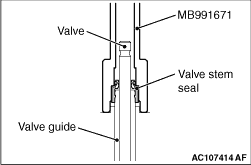

Inlet valve stem seal

|

|

>>A<<

|

42.

|

Exhaust valve stem seal

|

).

). ).

). ).

). ).

). ).

).