|

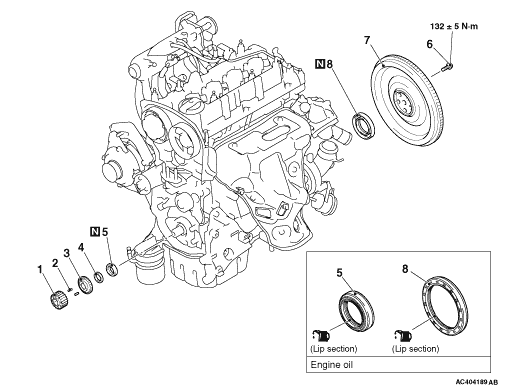

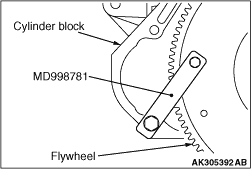

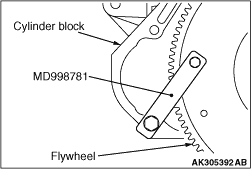

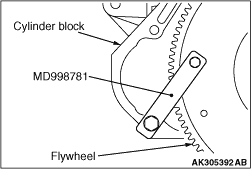

1.Use special tool flywheel stopper (MD998781) to secure the flywheel.

2.Remove the flywheel bolts.

|

|

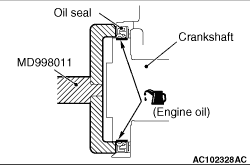

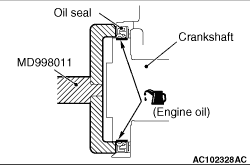

1.Apply a small amount of new engine oil to the entire inner diameter of the oil seal lip.

2.Use following special tool crankshaft rear oil seal installer (MD998011) to press-fit

the oil seal.

|

|

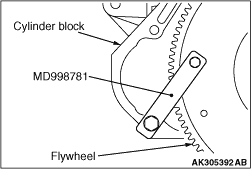

1.Use special tool flywheel stopper (MD998781) to secure the flywheel in the same manner

as removal.

2.Tighten the flywheel bolts to the specified torque.

Tightening torque: 132 ± 5 N·m

|

|

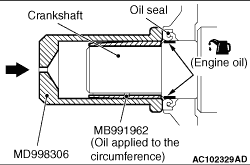

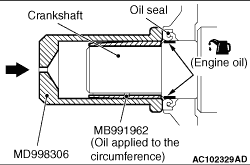

1.Apply a small amount of engine oil to the outer diameter of special tool crankshaft front

oil seal guide (MB991962) and install it to the crankshaft.

2.Apply a small amount of engine oil to the entire inner diameter of the oil seal lip.

3.Use special tool crankshaft front oil seal installer (MD998306) to press-fit the oil

seal.

|

|

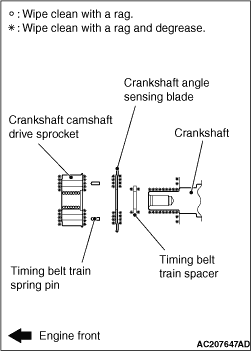

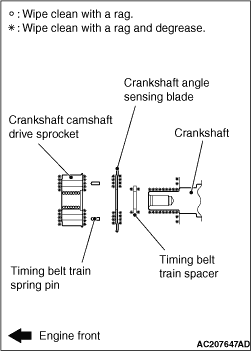

1.Wipe off the dirt on the crankshaft camshaft drive sprocket as shown in the figure using

a rag.

2.Wipe off the dirt on the crankshaft, the timing belt train spacer, the crankshaft

angle sensing blade and the crankshaft camshaft drive sprocket as shown in the figure using

a rag, and then degrease the areas.

| note |

Degrease them to prevent drop in the friction coefficient of the pressed area which is

caused by oil adhesion.

|

|

|

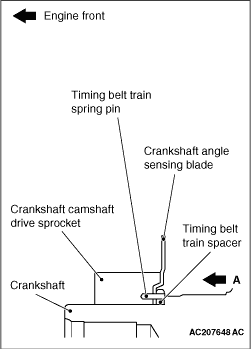

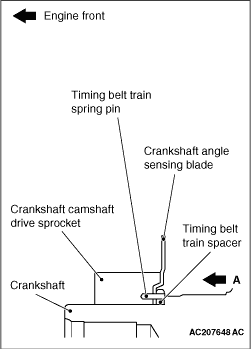

3.Install the balancer timing belt train spring pin, crankshaft angle sensing blade and

timing belt train spacer to the crankshaft camshaft drive sprocket.

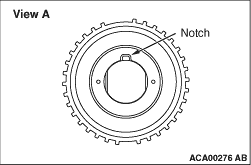

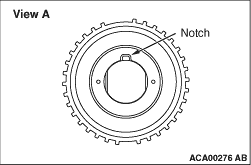

4.Fit the protrusion of the crankshaft camshaft drive sprocket with the crankshaft angle

sensing blade, and install them to the crankshaft.

|