|

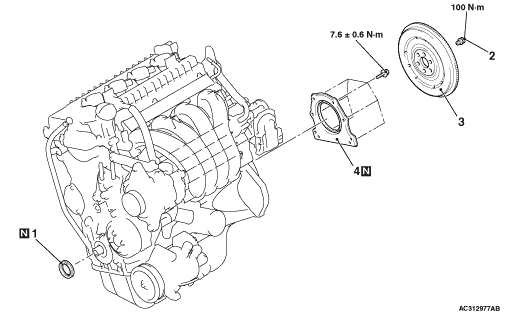

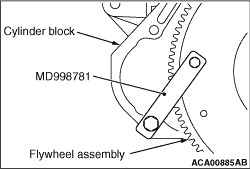

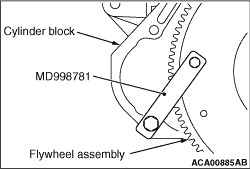

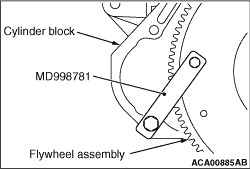

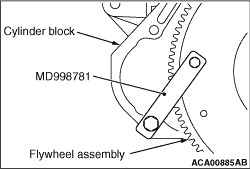

1.Use special tool flywheel stopper (MD998781) to secure the flywheel assembly.

2.Remove the flywheel bolts.

|

|

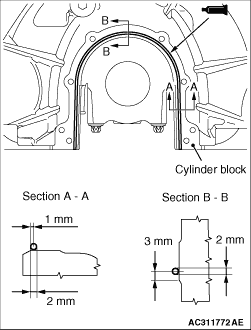

|

1.Remove sealant from the crankshaft rear oil seal case assembly mounting surface of

the cylinder block.

|

|

|

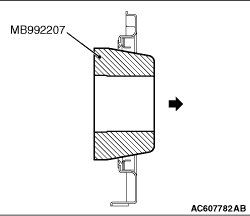

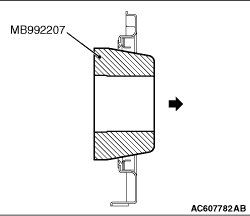

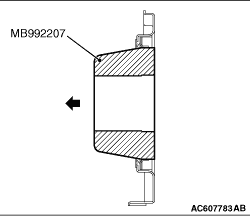

2.Apply a small amount of engine oil to the outer diameter of special tool oil seal

guide (MB992207).

|

|

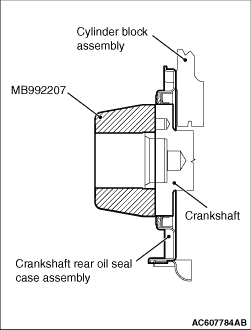

3.Pass the special tool oil seal guide (MB992207) through the crankshaft rear oil seal case

assembly in the direction shown in the figure (opposite to the direction of the crankshaft rear

oil seal case assembly installation).

| note |

This adjusts the direction of the oil seal lip.

|

|

|

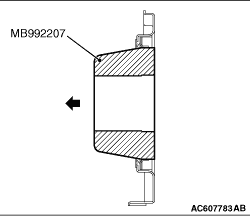

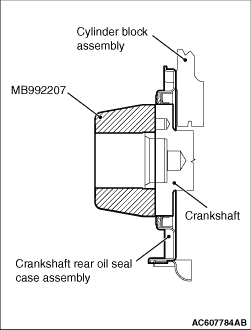

4.Install the special tool oil seal guide (MB992207) to the crankshaft rear oil seal case

assembly in the opposite direction from the direction in step 3 (in the direction of the crankshaft

rear oil seal case assembly installation).

|

|

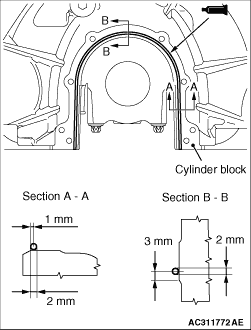

5.Apply a bead of specified sealant to the crankshaft rear oil seal case assembly mating

surface of the cylinder block as shown.

Specified sealant: ThreeBond 1217G or equivalent

| note |

Install the crankshaft rear oil seal case assembly immediately after applying sealant.

|

|

|

6.

| caution |

Install the crankshaft rear oil seal case assembly not

to damage the crankshaft rear oil seal.

|

Install the special tool oil seal guide (MB992207) to the crankshaft.

7.

| caution |

After the installation, until a sufficient period of time (one hour or

more) elapses, do not apply the oil or water to the sealant application area or start the engine.

|

Tighten the crankshaft rear oil seal case assembly mounting bolts to the specified torque.

Tightening torque: 7.6 ± 0.6 N·m

|

|

|

1.Remove the sealant, the engine oil and other adhering materials from the flywheel

assembly installation face, the crankshaft screw hole and flywheel bolts.

|

|

|

2.Install the flywheel assembly to the crankshaft.

|

|

3.Use special tool flywheel stopper (MD998781) to secure the flywheel assembly in the same

manner as removal.

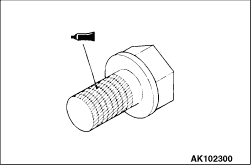

4.Apply a small amount of engine oil to the face of the flywheel bolt and the crankshaft

screw hole.

|

|

5.Apply specified sealant to the flywheel bolt threads.

Specified sealant: LOCTITE 2701 or equivalent

|

|

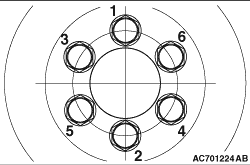

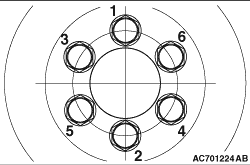

6.Tighten the flywheel bolts to the specified torque in two or three steps in the order

shown in the illustration.

Tightening torque: 100 N·m

|

|

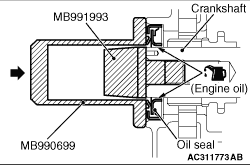

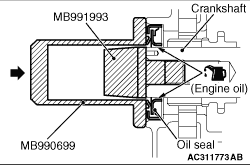

1.Apply a small amount of engine oil to the outer circumference of special tool crankshaft

front oil seal guide (MB991993) and install it to the crankshaft.

2.Apply a small amount of engine oil to the entire inner circumference of the oil seal

lip.

3.

| caution |

Install the crankshaft front oil seal not to damage the crankshaft

front oil seal.

|

Using special tool differential oil seal installer (MB990699), drive the oil seal so that

it is flush with the timing chain case assembly.

|