|

1.The headlamps should be aimed with the proper beam setting equipment, and in accordance

with the equipment manufacture’s instructions.

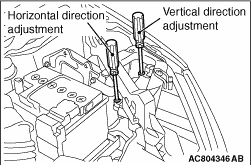

2.Alternately turn the adjusting screw to adjust the headlamp aiming.

|

|

|

1.Inspect for badly rusted or faulty headlamp assemblies.

|

|

|

2.These conditions must be corrected before a satisfactory adjustment can be made.

|

|

|

3.Inspect tyre inflation, and adjust if it is necessary.

|

|

|

4.If the fuel tank is not filled up, put weight in the luggage compartment to make up

for the fuel shortage so that the weight will become 90% of full-state weight or heavier.

(0.8 kg per litter)

|

|

|

5.There should be no other load in the vehicle other than driver or substituted weight

of approximately 75 kg placed in driver’s position.

|

|

|

6.Turn the headlamp levelling switch to the switch position "0." <Vehicles

with headlamp manual levelling system>

|

|

|

7.Thoroughly clean the headlamp lenses.

|

|

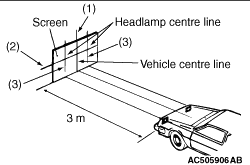

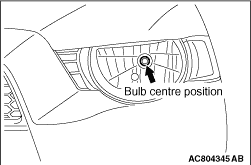

8.Place the vehicle on a level floor, perpendicular to a flat screen 3 m away from the bulb

centre position of the low-beam.

9.Rock vehicle sideways to allow vehicle to assume its normal position.

10.To correct for distortion of the suspension, rock the bumpers on the front/rear

side of the vehicle up and down three times alternately.

11.Run the engine at a speed of 2,000 r/min to charge the battery.

12.Four lines of adhesive tape (or equivalent markings) are required on screen or wall:

(1)

Position a vertical tape or mark so that it is aligned with the vehicle centre line.

(2)

Measure the distance from the bulb centre position to the floor. Transfer the measurement

to the screen. Horizontal tape or mark on the screen is for reference of vertical adjustment.

(3)

Measure the distance from the centre line of the vehicle to the centre of each headlamp.

Transfer the measurement to the screen. Vertical tape or mark on the screen with reference to

the centre line of each headlamp bulb.

|

|

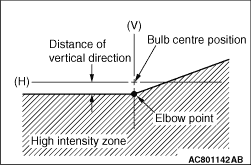

- The low-beam headlamp should project on the screen upper

edge of the beam (cut-off).

- If not the case, turn the adjusting screws to achieve the specified low-beam cut-off location

on the aiming screen.

|

|

Standard value:

Vertical direction; 36 mm (0.69°) below horizontal line (H)

Horizontal direction; Elbow point intersects the vertical line (V)

Limit:

Vertical direction; Between 21 mm (0.4°) to 51 mm (0.98°) downward

from the horizontal line (H)

Horizontal direction; ± 26 mm (± 0.5°) from the vertical

line (V)

| note |

The illustration shows LH drive vehicles. For RH drive vehicles, it is symmetrical.

|

|