|

|

Measure wheel alignment with alignment equipment on a

level surface. The front suspension, steering system, wheels, and tires should be serviced to

normal condition before measuring wheel alignment.

|

|

|

Standard value:

At the centre of tyre tread: 0 ± 2 mm

Toe-angle (per wheel): 0°00’ ± 0°06’

|

|

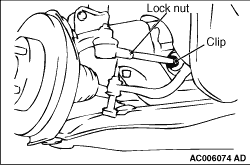

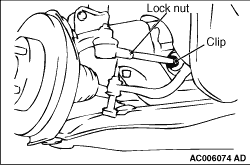

1.Adjust the toe-in by undoing the clip and lock nut, and turning the left and right tie

rod turnbuckles by the same amount (in opposite directions).

| note |

The toe will move out as the left turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear of the vehicle.

|

2.Install the clip and tighten the lock nut to the specified torque.

Tightening torque: 43 ± 7 N·m

3.Confirm that the toe-in is at the standard value.

4.Use a turning radius gauge to check that the steering angle is at the standard value.

|

|

|

To check the steering linkage, especially after the vehicle has been involved in an accident

or if an accident is presumed, it is advisable to check the toe-out angle on turns in addition

to the wheel alignment.

|

|

|

Conduct this test on the left turn as well as on the right turn.

|

|

|

Standard value:

Toe-out angle on turns (inner wheel when outer wheel at 20°)

|

21°21’

|

|

|

|

Standard value:

Item

|

Standard suspension

|

High ground clearance suspension

|

Camber

|

-0°30’ ± 0°30’*

|

-0°15’ ± 0°30’*

|

Caster

|

2°40’ ± 0°30’*

|

2°30’ ± 0°30’*

|

Kingpin inclination

|

13°20 ’± 0°30’

|

13°00’ ± 0°30’

|

|

|

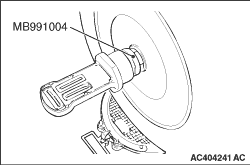

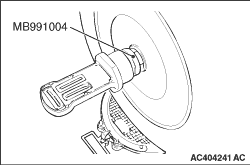

| note |

For vehicles with aluminium wheels, attach the camber/caster/kingpin

gauge to the driveshaft by using special tool wheel alignment gauge attachment (MB991004). Tighten

the special tool to the same torque 236 ± 19 N·m as the driveshaft nut.

|

|