|

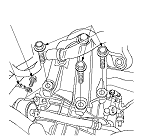

Special Tools Required

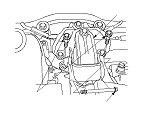

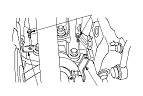

Engine support hanger

AAR-T1256-J00

*

Subhanger stay

07MAK-PY30100

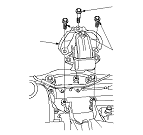

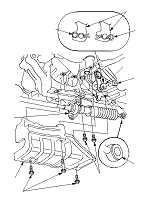

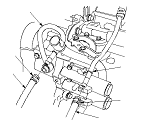

Subframe alignment pin

070AG-SJAA10S

*: This special tool is available from Snap-on Tools International, LLC.

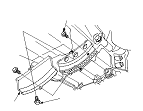

NOTE: Use fender covers to avoid damaging painted surfaces.

K24Z3 Engine Model

-

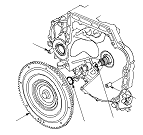

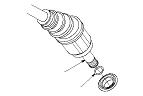

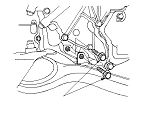

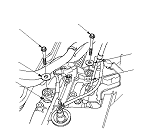

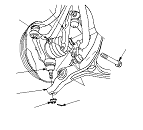

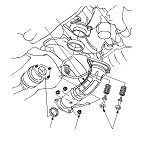

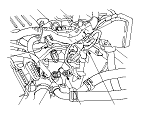

Install a new O-ring (A) the torque converter (B), then install the torque converter on the mainshaft (C).

-

Install the 14 x 20 mm dowel pins (D) in the torque converter housing.

-

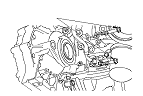

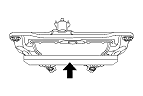

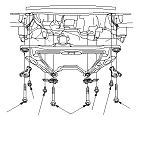

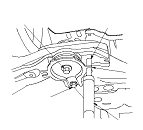

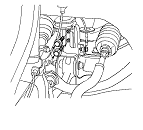

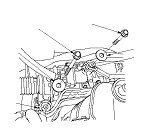

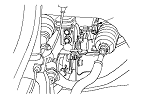

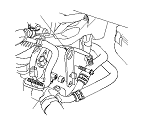

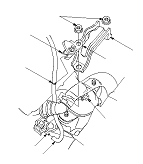

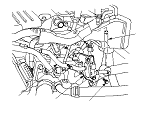

Place the transmission on a jack, and raise the transmission to the engine level, then fit the transmission to the engine.

|