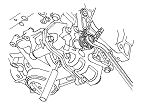

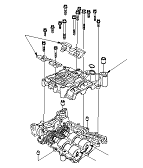

Engine Oil Pump Overhaul

|

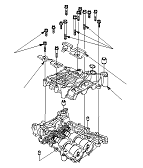

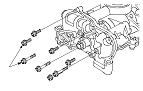

Exploded View

Special Tools Required

Pin driver, 6.0 mm

07744-0010500

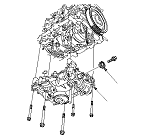

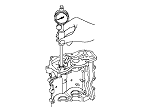

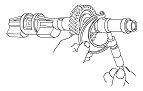

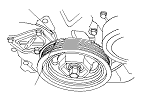

Oil Pump Removal

|

|

|

|

|

|

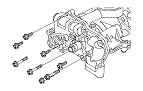

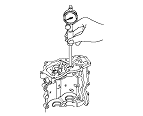

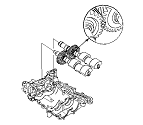

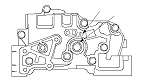

Oil Pump Inspection

|

|

||||||||

|

||||||||

|

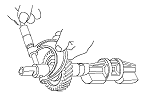

Balancer Shaft Inspection

|

||||||||

|

|

|

|||||||||||||||

|

|||||||||||||||||||||

|

|||||||

|

|

|

|

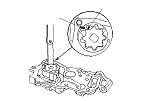

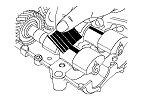

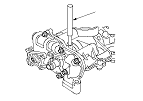

Oil Pump Installation

|

|

|

|

|

|