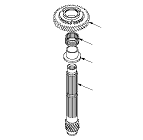

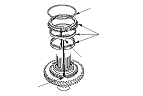

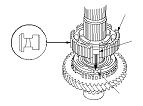

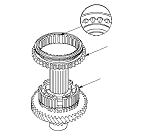

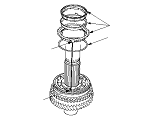

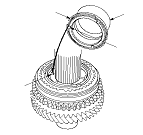

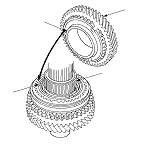

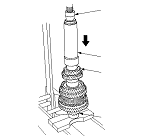

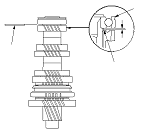

M/T Countershaft Reassembly

|

Exploded View

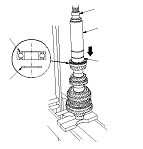

Special Tools Required

Inner driver handle, 40 mm

07746-0030100

Inner bearing driver attachment, 30 mm

07746-0030300

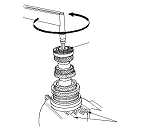

NOTE: Refer to the Exploded View, as needed, during this procedure.

|

|

|

|

|

|

|

|

|

|

|

|

|

|