Clutch Replacement

|

Special Tools Required

Slide hammer weight

07741-0010201

Bearing remover shaft

07936-3710600

Driver handle, 15 x 135L

07749-0010000

Bearing driver attachment, 22 x 24 mm

07746-0010800

Ring gear holder

07LAB-PV00100

Shaft (clutch alignment tool),

07PAF-0020100

Taper cone (clutch alignment tool),

07PAF-0020200

Clutch alignment pilot, 21 mm

07PAF-0020370

Remover handle

07936-3710100

NOTE: The illustrations show K24Z3 engine model.

Engine Side

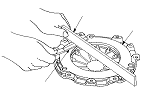

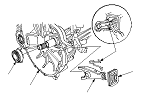

Pressure Plate Inspection and Removal

|

|

|

|

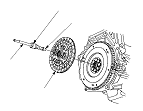

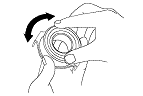

Clutch Disc Inspection and Removal

|

|

|||||||||||||||||||

|

|||||||||||||||||||

|

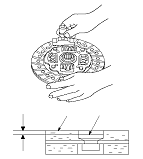

Flywheel Inspection

|

|

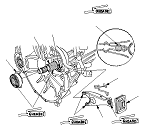

Flywheel Replacement

|

|

|

Crankshaft Pilot Bushing Inspection

|

|

Crankshaft Pilot Bushing Replacement

|

|

|

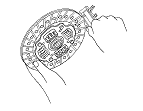

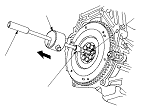

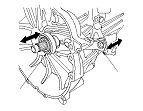

Clutch Disc and Pressure Plate Installation

|

|

|

|

Transmission Side

Release Bearing Removal

|

|

Release Bearing Inspection

|

|

Release Bearing Installation

|

|