LKAS Camera Aiming

|

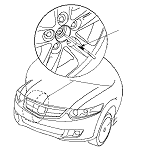

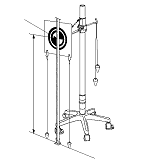

Special Tools Required

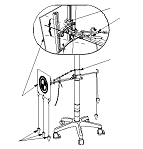

Rader aimer set

070AJ-SDA0100

or Camera/rader aimer set 070AJ-SDA0300*

*Available by rental from Honda Motor Europe Ltd. for Europe market

Prepare the items shown

NOTE: The LKAS camera must be re-aimed if the LKAS camera unit is removed, replaced or if aiming error occurs. When aiming is not finished, an LKAS indicator and a DTC is stored.

Cautions for the operation environment

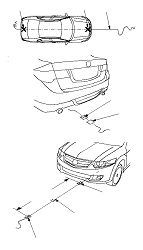

Set Up the vehicle

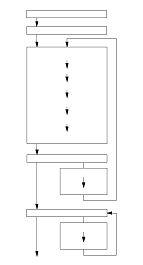

LKAS camera adjustment procedure

There are Static Aiming and Dynamic Aiming procedures, and they need to be done in that order.

|

|

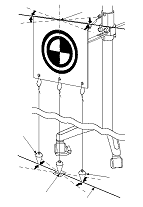

Precaution for the static camera aiming

To complete the aiming, it is necessary to succeed all of three targets (center, passenger's side, driver's side) detections. If the detection for any one of targets failed or aborted on the way, the condition will be the aiming uncompleted.

When the static camera aiming was failure for some reason, aiming failure code is displayed on the HDS. In this case,

troubleshoot the indicated failure code with the HDS.

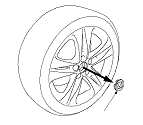

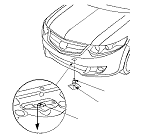

Vehicle Preparation

|

|

|

|

|

|

|

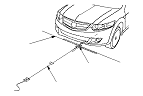

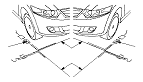

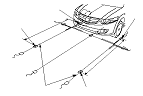

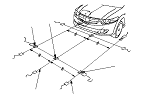

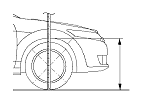

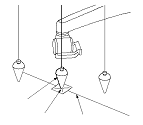

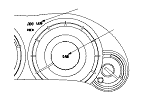

Target pattern surface height adjustment and positioning

|

|

|

|

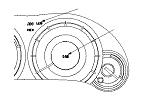

Implementation of the Static Camera Aiming

The static camera aiming status

|

|

|

|

The static camera aiming status

|

|

Precaution for the Dynamic Camera Aiming

Carry out the dynamic camera aiming on a road that has parallel and horizontal lanes that will allow the vehicle to be driven at speeds between 72−112 km/h (45−70 mph) for 10 minutes or more. The aiming will fail unless this is completed within 30 minutes. The dynamic camera aiming may not be successful if it is attempted in bad weather such as rain, fog or snow. The white or yellow lines on the road are not clearly visible due to the reflections caused by a wet road surface. When you do the dynamic camera aiming in the dark, turn the headlights on and ensure that the windscreen and headlights are clean. If the dynamic camera aiming fails for some reason, an aiming failure code is displayed on the HDS. In this case, carry out the troubleshooting for the code indicated using the HDS.

Implementation of the dynamic camera aiming

The dynamic camera aiming status

|

The dynamic camera aiming status

|