|

Special Tools Required

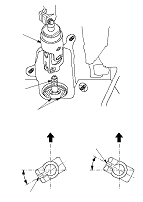

Ball joint remover, 28 mm

07MAC-SL00201

Subframe alignment pin

070AG-SJAA10S

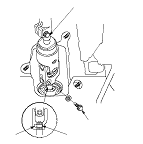

Engine support hanger

AAR-T1256-J00*

Subhanger stay

07MAK-PY30100

*: This special tool is available from Snap-on Tools International, LLC.

Note these items during removal:

-

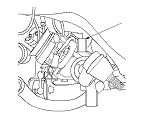

Use solvent and a brush, wash any oil and dirt off the end of the steering gearbox. Avoid any electrical parts. Blow dry with compressed air.

-

Be sure to remove the steering wheel before disconnecting the steering joint, or damage to the cable reel can occur.

-

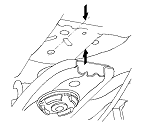

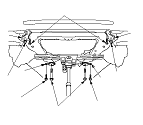

Lower the front subframe from the body and remove the steering gearbox through the gap produced by lowering the front subframe.

-

The illustrations show LHD model, RHD model is similar for items not shown in this section.

Removal

-

-

-

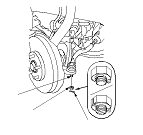

Remove the front wheels.

-

-

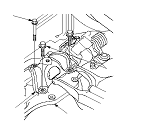

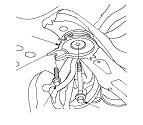

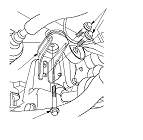

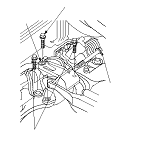

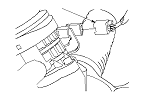

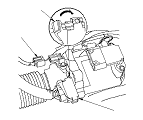

Remove the steering joint cover (A).

|