-

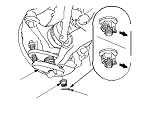

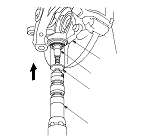

Using a yellow oil-based paint marker, paint a mark (A) to top of the knuckle ball joint as shown.

NOTE: The paint mark is used to identify a knuckle that has had the ball joint replaced. Do not replace the ball joint with the paint mark;

you must replace the knuckle.

-

Install all of the removed parts in the reverse order of removal, and note these items:

-

First install all the components, and lightly tighten the bolts and the nuts, then raise the suspension to load it with the vehicle's weight before fully tightening it to the specified torque values. Do not place the jack against the ball joint pin of the knuckle.

-

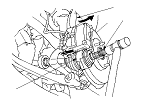

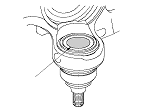

Be careful not to damage the ball joint boot when connecting the knuckle.

-

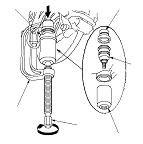

Before connecting the ball joint, degrease the threaded section and the tapered portion of the ball joint pin, and the ball joint connecting hole, and the threaded section and the mating surfaces of the castle nut.

-

Torque the castle nut to the lower torque specification, then tighten it only far enough to align the slot with the ball joint pin hole. Do not align the castle nut by loosening it.

-

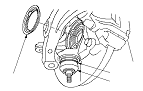

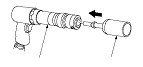

Use a new spindle nut on reassembly.

-

Before installing the spindle nut, apply a small amount of engine oil to the seating surface of the nut. After tightening, use a drift to stake the spindle nut shoulder against the driveshaft.

-

Before installing the wheel, clean the mating surfaces of the brake disc and the inside of the wheel.

-

-

|

|